Preparation process for high-strength concrete

A high-strength concrete and preparation technology, applied in the field of concrete, can solve the problems of concrete toughness, strength improvement is not significant, strength and other properties are not very significant, and the possibility of winding is reduced, so as to improve the mechanical properties and overall stability, surface hydroxyl Enriches and improves the effect of tight junctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

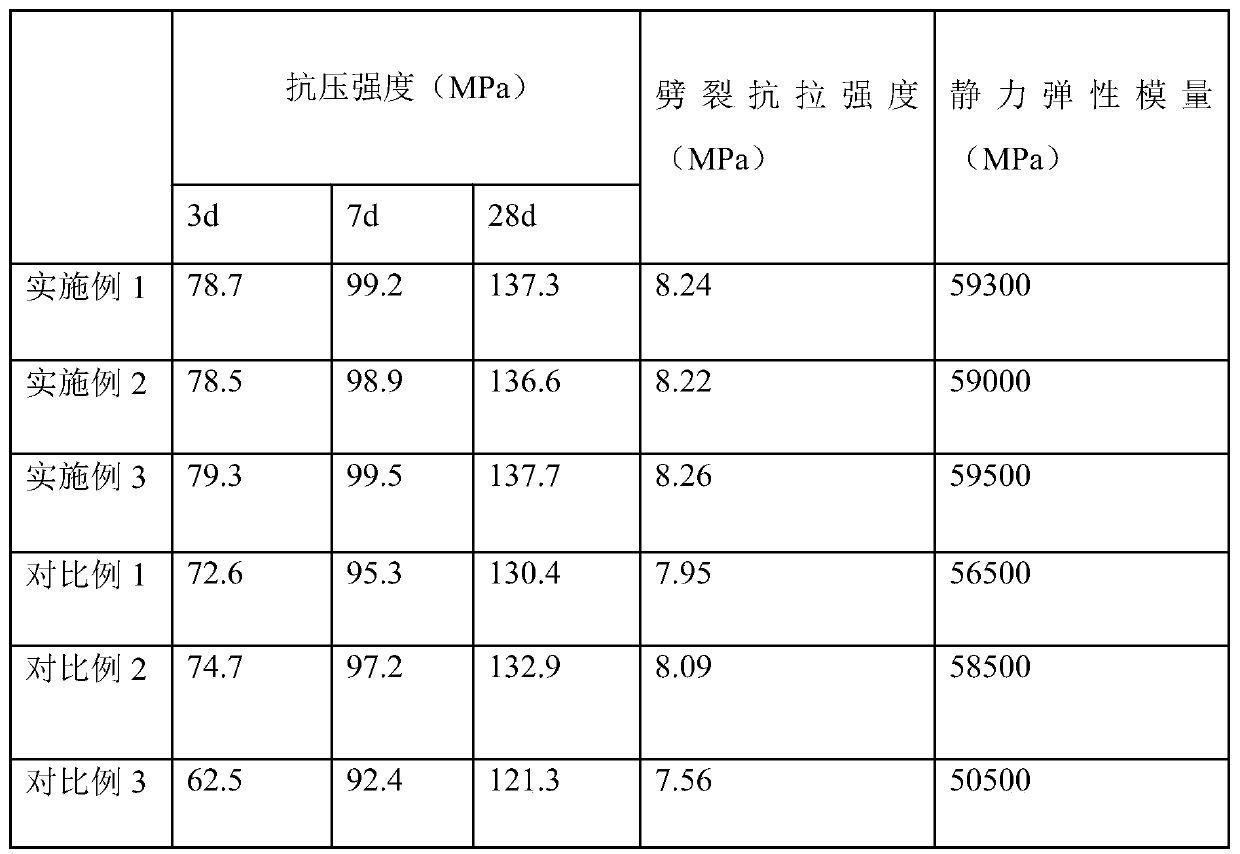

Examples

Embodiment 1

[0025] The preparation process of high-strength concrete of this embodiment includes the following steps:

[0026] Step 1: Mix coarse aggregate and fine aggregate according to a weight ratio of 2:1 and add them to the mixer for mixing. Stir for 1 hour until the coarse and fine aggregates are completely mixed, and then add modified alkali lignin and low-viscosity cellulose Ether, the stirring speed is increased to 200r / min, stirring for 20 minutes, then nano fillers are added, and the stirring is continued for 20 minutes, then the compatibilizer is added, and finally Portland cement and deionized water are added, the stirring speed is reduced to 100r / min, and stirring is performed for 1 hour , Get the initial mixture;

[0027] Step 2: Feed the primary mixture, cotton fiber, and modified steel fiber obtained in step 1 into a high-speed mixer for mixing, at a mixing speed of 1000r / min, and a mixing time of 30min, to obtain a secondary mixture;

[0028] Step three, send the spare second...

Embodiment 2

[0038] The preparation process of high-strength concrete of this embodiment includes the following steps:

[0039] Step 1: Mix coarse aggregate and fine aggregate according to a weight ratio of 2:1 and add them to the mixer for mixing. Stir for 2 hours until the coarse and fine aggregates are completely mixed, and then add modified alkali lignin and low-viscosity cellulose Ether, the stirring speed is increased to 300r / min, stirring for 30 minutes, then nano fillers are added, and the stirring is continued for 30 minutes, then the compatibilizer is added, and finally Portland cement and deionized water are added. The stirring speed is reduced to 100r / min, and stirring is carried out for 2 hours. , Get the initial mixture;

[0040] Step 2: Send the primary mixture, cotton fiber, and modified steel fiber obtained in step 1 into a high-speed mixer for mixing, at a mixing speed of 2000r / min, and a mixing time of 40min, to obtain a secondary mixture;

[0041] Step three, send the spare s...

Embodiment 3

[0051] The preparation process of high-strength concrete of this embodiment includes the following steps:

[0052] Step 1: Mix coarse aggregate and fine aggregate according to a weight ratio of 2:1 and add them to the mixer for mixing, stirring for 1.5h until the coarse and fine aggregates are completely mixed, and then add modified alkali lignin and low viscosity fiber For plain ether, increase the stirring speed to 250r / min, stir for 25 minutes, add nano fillers, continue stirring for 25 minutes, add compatibilizers, and finally add Portland cement and deionized water, and stir at 100r / min. 1.5h, get the initial mixture;

[0053] Step 2: Feed the primary mixture, cotton fiber, and modified steel fiber obtained in Step 1 into a high-speed mixer for mixing, at a mixing speed of 1500r / min, and a mixing time of 35min, to obtain a secondary mixture;

[0054] Step three, send the spare secondary mixture of step two into the plasma reactor for low-temperature plasma treatment, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com