Super junction device structure and preparation method thereof

A super-junction device and column structure technology, which is applied in the field of super-junction device structure and its preparation, can solve problems such as uneven defects in the super-junction drift region, and achieve the effects of optimizing reverse recovery characteristics, low cost, and increasing recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

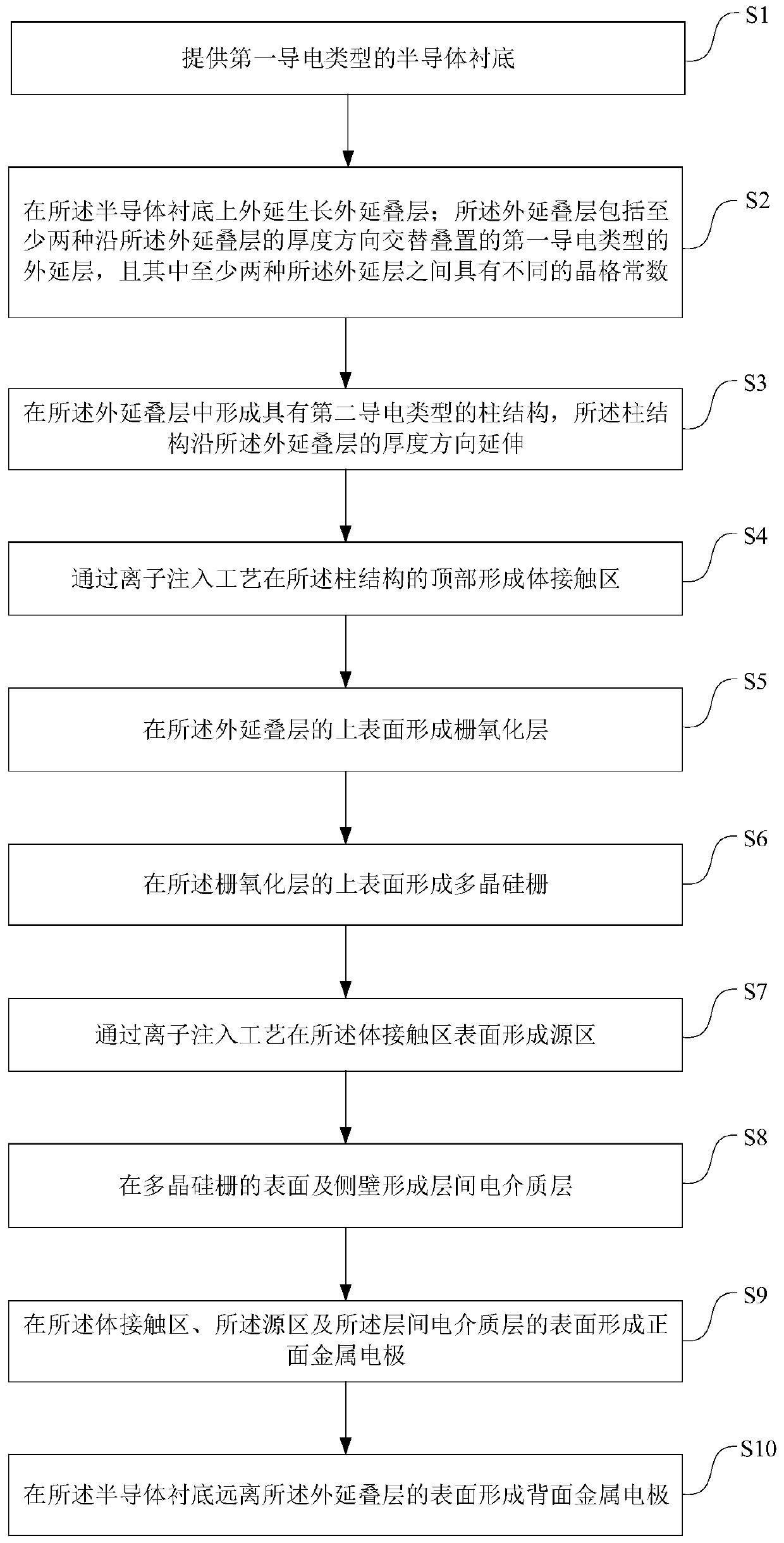

[0083] see Figure 1 to Figure 14 , the invention provides a method for preparing a superjunction device structure, comprising the following steps:

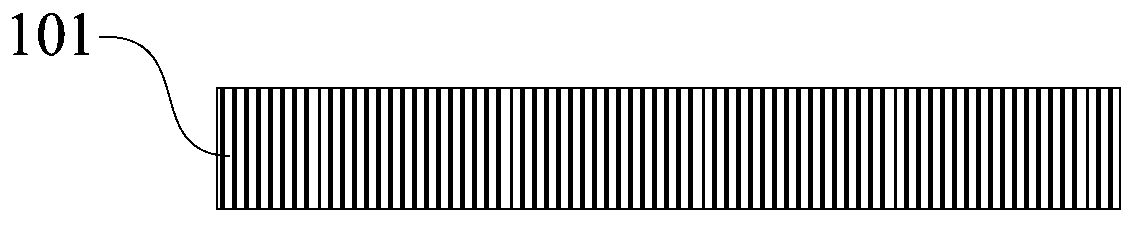

[0084] 1) providing a semiconductor substrate 101 of the first conductivity type;

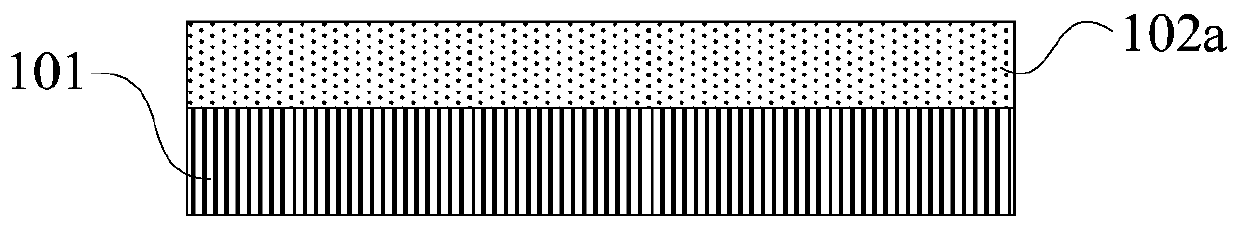

[0085] 2) epitaxially growing an epitaxial stack 102 on the semiconductor substrate 101; the epitaxial stack 102 includes at least two epitaxial layers of the first conductivity type stacked alternately along the thickness direction of the epitaxial stack 102, and wherein at least two of the epitaxial layers have different lattice constants;

[0086] 3) Forming a column structure 103 of the second conductivity type in the epitaxial stack 102 , and the column structure 103 extends along the thickness direction of the epitaxial stack 102 .

[0087] In step 1), see figure 1 The S1 step and figure 2 , providing a semiconductor substrate 101 of the first conductivity type. figure 2 is a schematic cross-sectional view of the semiconductor substra...

Embodiment 2

[0127] Such as Figure 15 As shown, this embodiment provides a super junction device structure and its fabrication method. Compared with Embodiment 1, the difference of this embodiment is that the epitaxial stack 202 on the semiconductor substrate 201 includes three The epitaxial layers of the first conductivity type stacked alternately along the thickness direction of the epitaxial stack 202 specifically include a first epitaxial layer 202a, a second epitaxial layer 202b and a third epitaxial layer 202c.

[0128] As an example, in Figure 15 Among them, the first epitaxial layer 202a and the second epitaxial layer 202b are silicon germanium layers, and the third epitaxial layer 202c is a silicon layer. Wherein, germanium in the first epitaxial layer 202a and the second epitaxial layer 202b have different atomic percentages and percentages. Optionally, the atomic percent content of germanium in the first epitaxial layer 202a is 5%, and the atomic percentage content of german...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com