Waterproof plate frame integrated floor structure and production method thereof

A waterproof board and floor slab technology, which is applied in the direction of floor slabs, chemical instruments and methods, and hydraulic material layered products, can solve problems that cannot be applied to the field of prefabricated buildings, so as to prevent water seepage and return, improve assembly rate, and waterproof performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

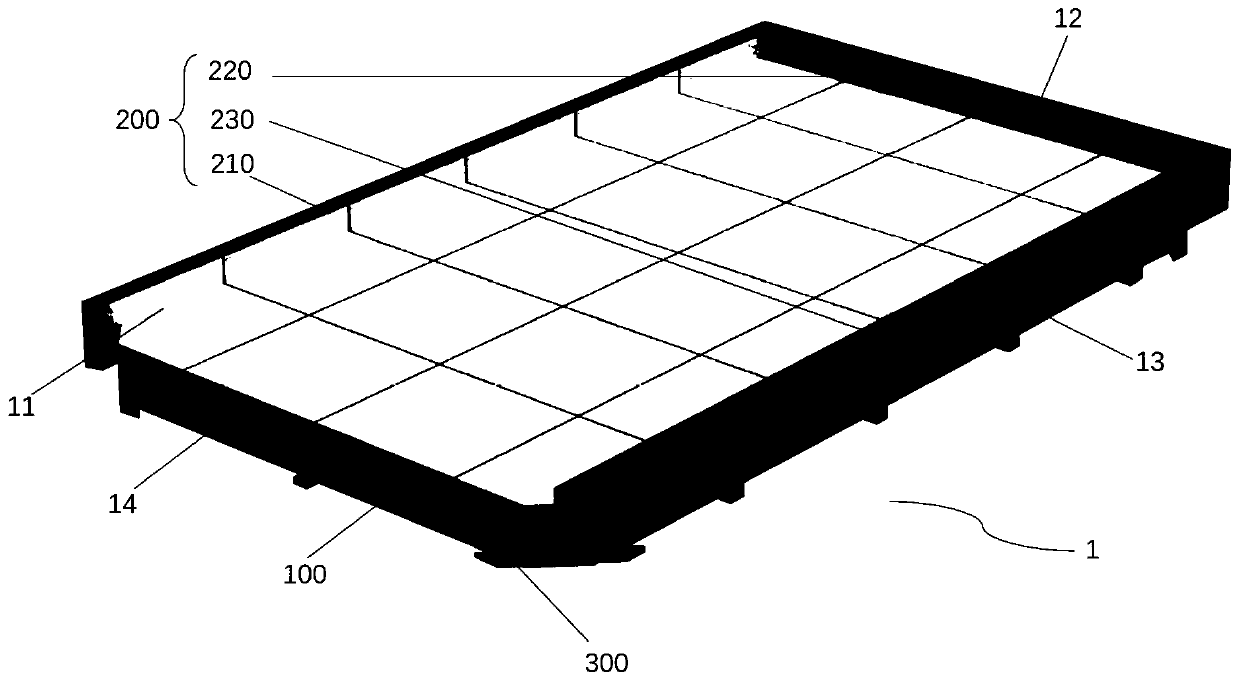

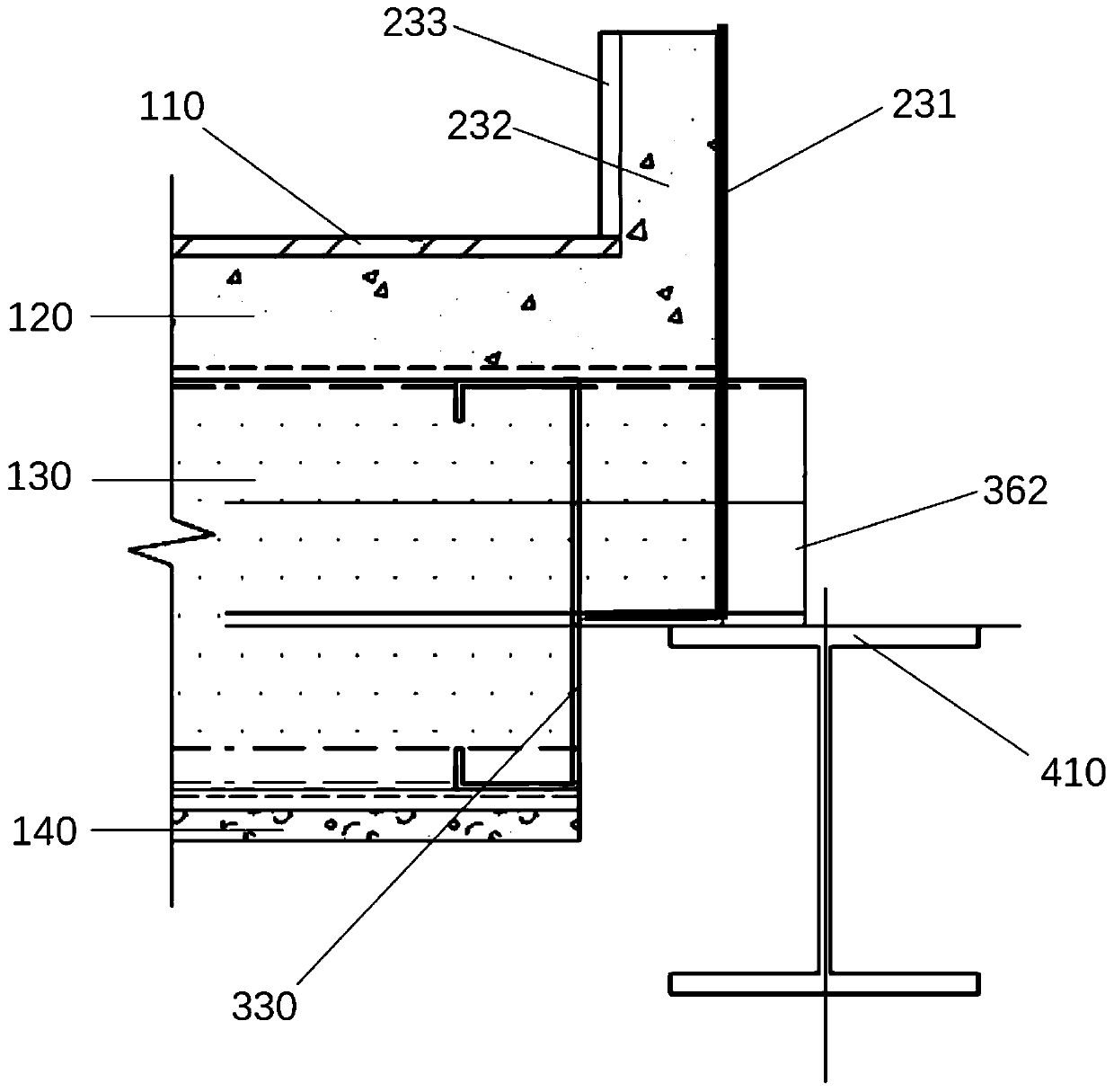

[0069] figure 1 A drawing of an exemplary flashing frame-in-one floor slab. like figure 1 As shown, the floor 1 of this embodiment is a quadrilateral, which includes a first edge 11 , a second edge 12 , a third edge 13 and a fourth edge 14 . The floor 1 includes a base layer 100 , a waterproof flange structure 200 and a floor steel frame structure 300 . Wherein, the floor steel frame structure 300 is embedded inside the base layer 100 . The waterproof cuff structure 200 includes a first waterproof cuff structure 210 , a second waterproof cuff structure 220 and a third waterproof cuff structure 230 . The first waterproof flange structure 210 is vertically disposed on the first edge 11 , the second waterproof flange structure 220 is vertically disposed on the second edge 12 and the third waterproof flange structure 230 is vertically disposed on the third edge 13 .

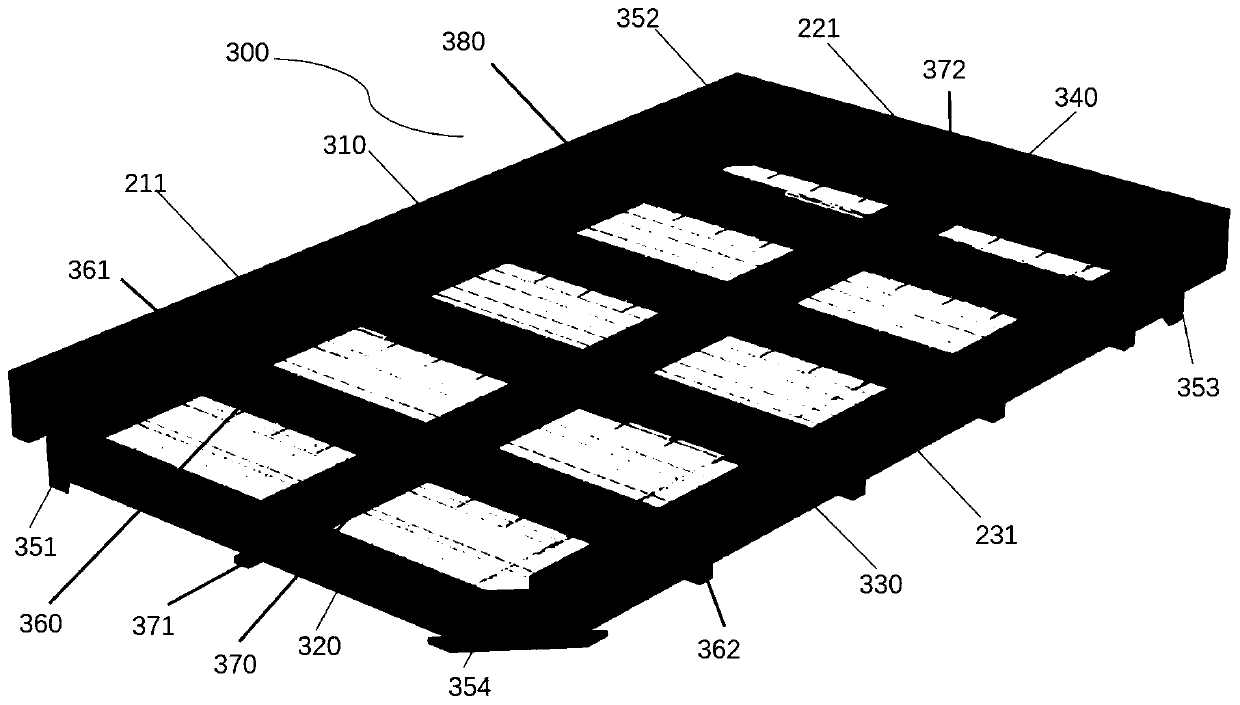

[0070] figure 2 It is a connection diagram of an exemplary floor steel frame structure and a waterproof flan...

Embodiment 2

[0076] This embodiment is a production method of a waterproof board frame combined with a floor slab structure, which includes the following steps:

[0077] 1. Lay out the line on the mold table of the production line, and set up the side formwork according to the size of the floor. At least one side of the mold table has a groove suitable for the waterproof flanging structure;

[0078] 2. The anti-beating process is to lay the tiles on the mold platform and the groove of the mold platform, and spray 3-5mm thick polymer mortar on the bottom of the tiles;

[0079] 3. Apply 20mm thick C30 fine stone concrete on the polymer mortar;

[0080] 4. Add welded steel wire mesh above the skeleton structure, add welded steel wire mesh on the bottom of the steel frame structure, hoist the steel frame structure into the formwork, and pour 500kg / m in the formwork 3 foam cement;

[0081] 5. Apply cement mortar on the surface of the concrete and press it into the grid cloth, remove the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com