Pile brace supporting structure screening method based on sacrifice yield rate

A technology of support structure and screening method, which is applied in basic structure engineering, excavation, instruments, etc., can solve the problems such as the influence of the safety performance of the parameter structure that cannot be truly reflected, the lack of consideration of similar points, and the improper handling of the head and tail points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

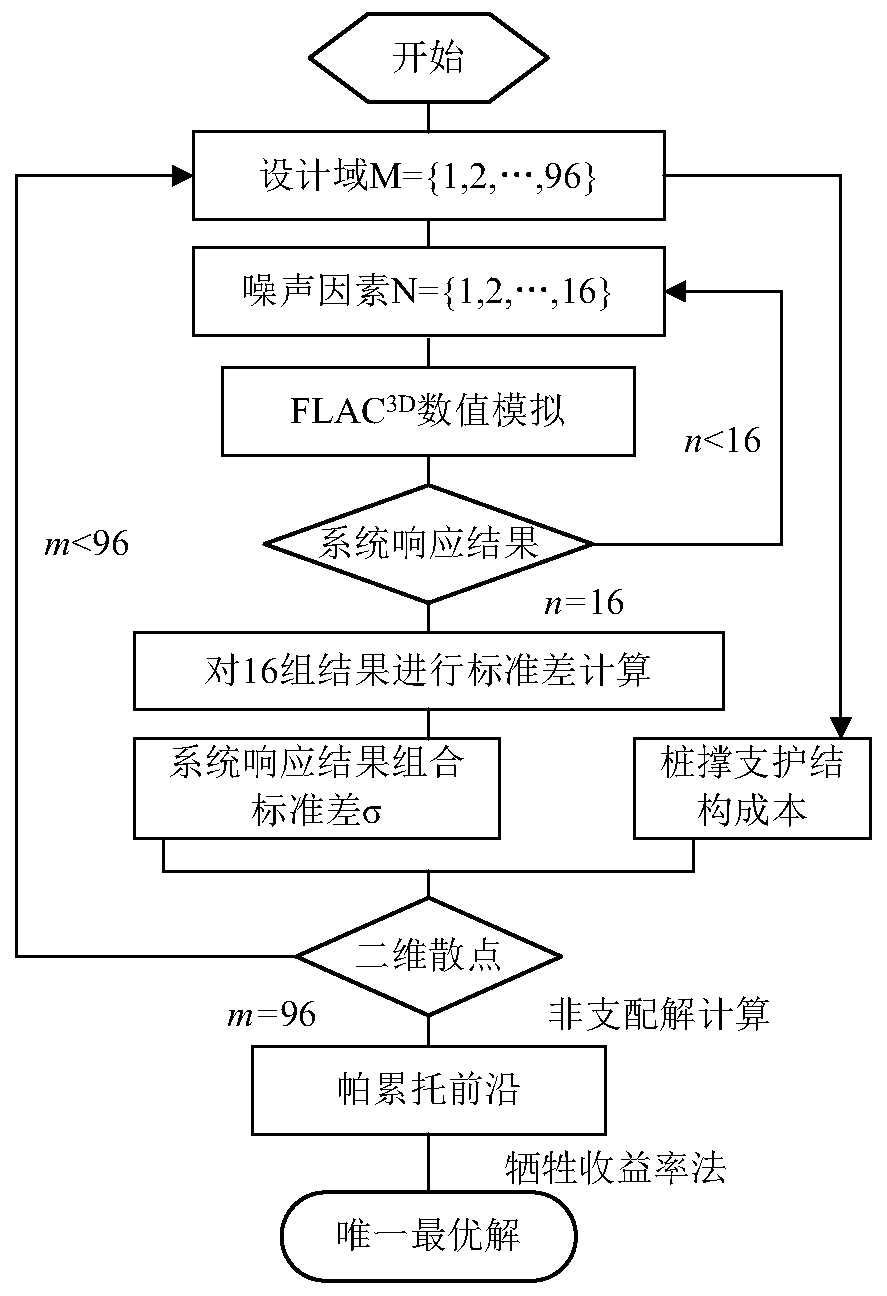

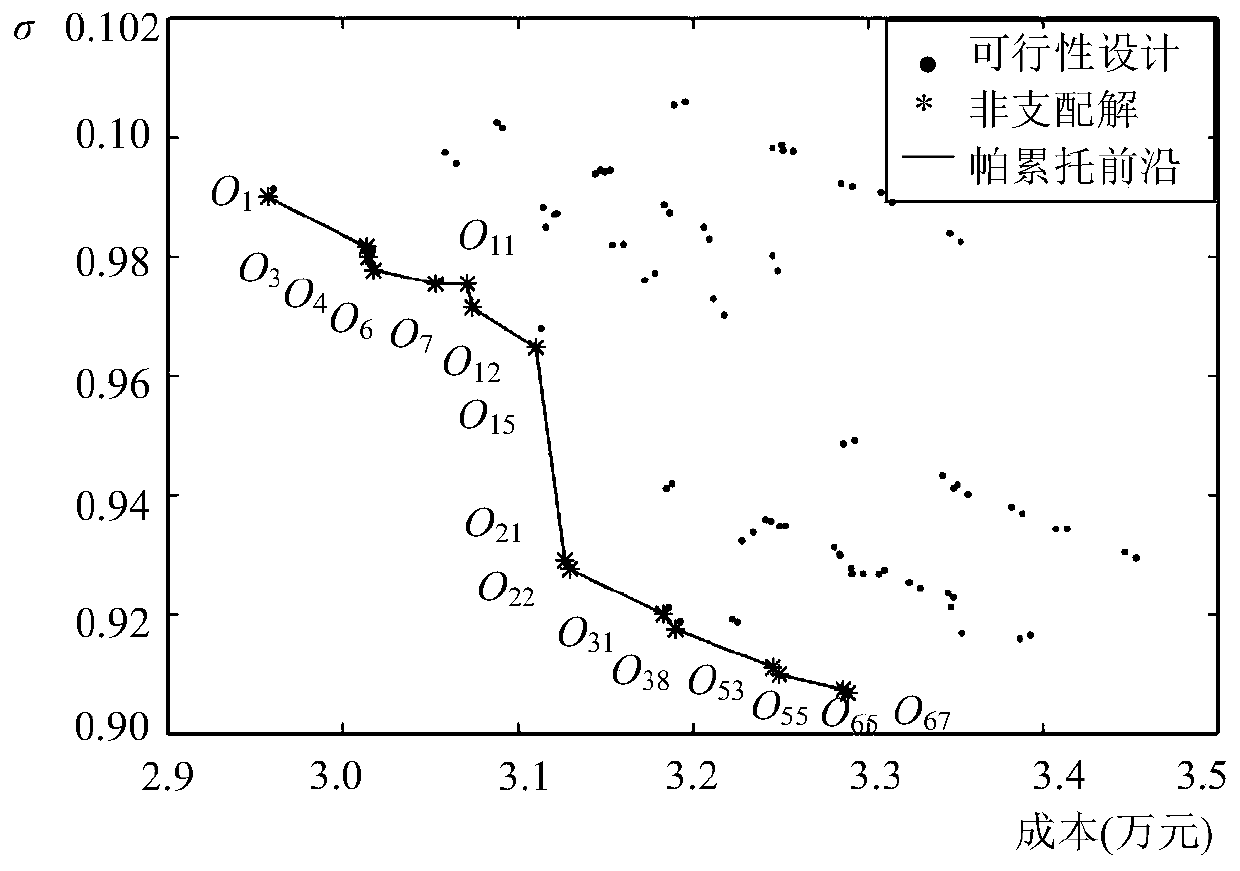

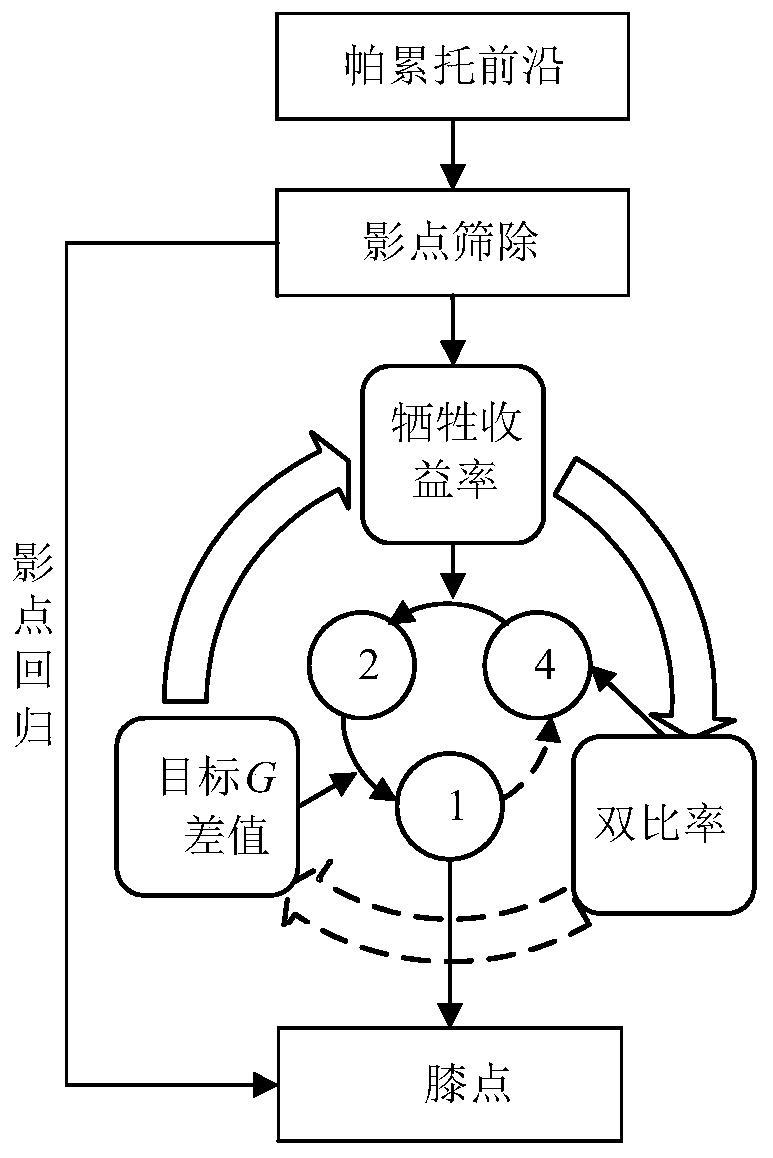

[0102] according to figure 1 The flow shown screens the pile support structure design scheme for the open-cut foundation pit of Qingxiushan Station Hall of Nanning Metro, and determines the foundation pit pile support structure with the lowest cost and the best robustness. The specific steps are as follows:

[0103] Step 1, design the foundation pit pile support structure according to the layout form and depth of the bored piles, the concrete material used, the internal support form, the concrete type and the column layout form, and form the feasible area of the foundation pit pile support structure;

[0104] The layout of bored piles is divided into Φ1200mm@1500mm and Φ1500mm@1700mm. The depth of bored piles is 35m and 40m. The concrete materials of bored piles are C35 and C30. Based on the foundation pit of bored piles There are 8 designs of pile support structure;

[0105] The internal support adopts the form of rectangular reinforced concrete internal support, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com