A kind of reduced graphene oxide-nickel base gradient coating and preparation method thereof

A graphene and gradient technology is applied in the field of reduced graphene oxide-nickel-based gradient coating and its preparation, and can solve the problems that the corrosion resistance of the coating needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

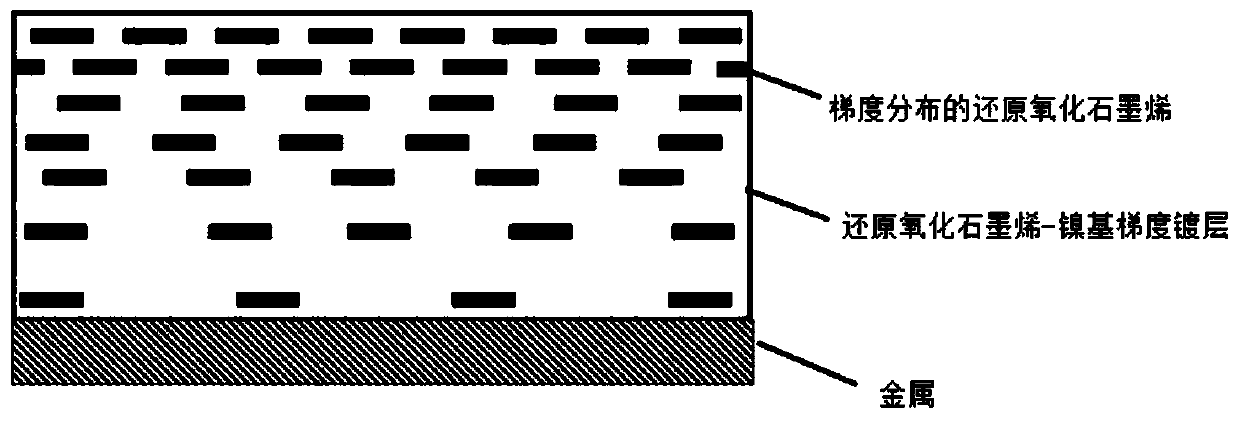

[0050] The invention provides a kind of preparation method of reduced graphene oxide-nickel base gradient coating, comprises the following steps:

[0051] Provide a plating solution, including graphene oxide in the plating solution;

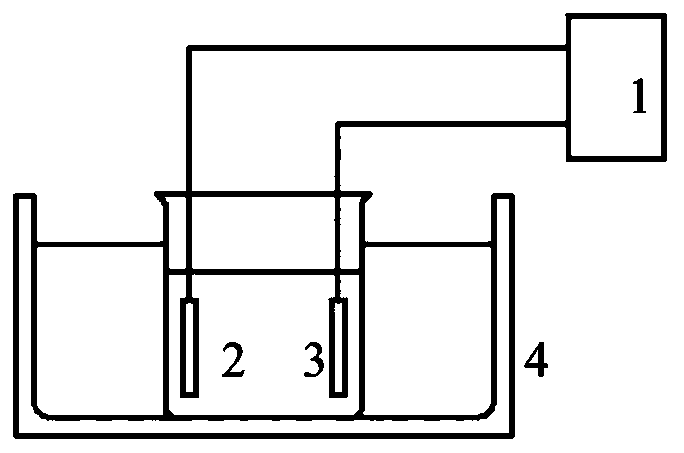

[0052] Using the nickel plate as the anode and the metal substrate to be plated as the cathode, using the plating solution for electroplating, forming a reduced graphene oxide-nickel-based gradient coating on the metal substrate to be plated;

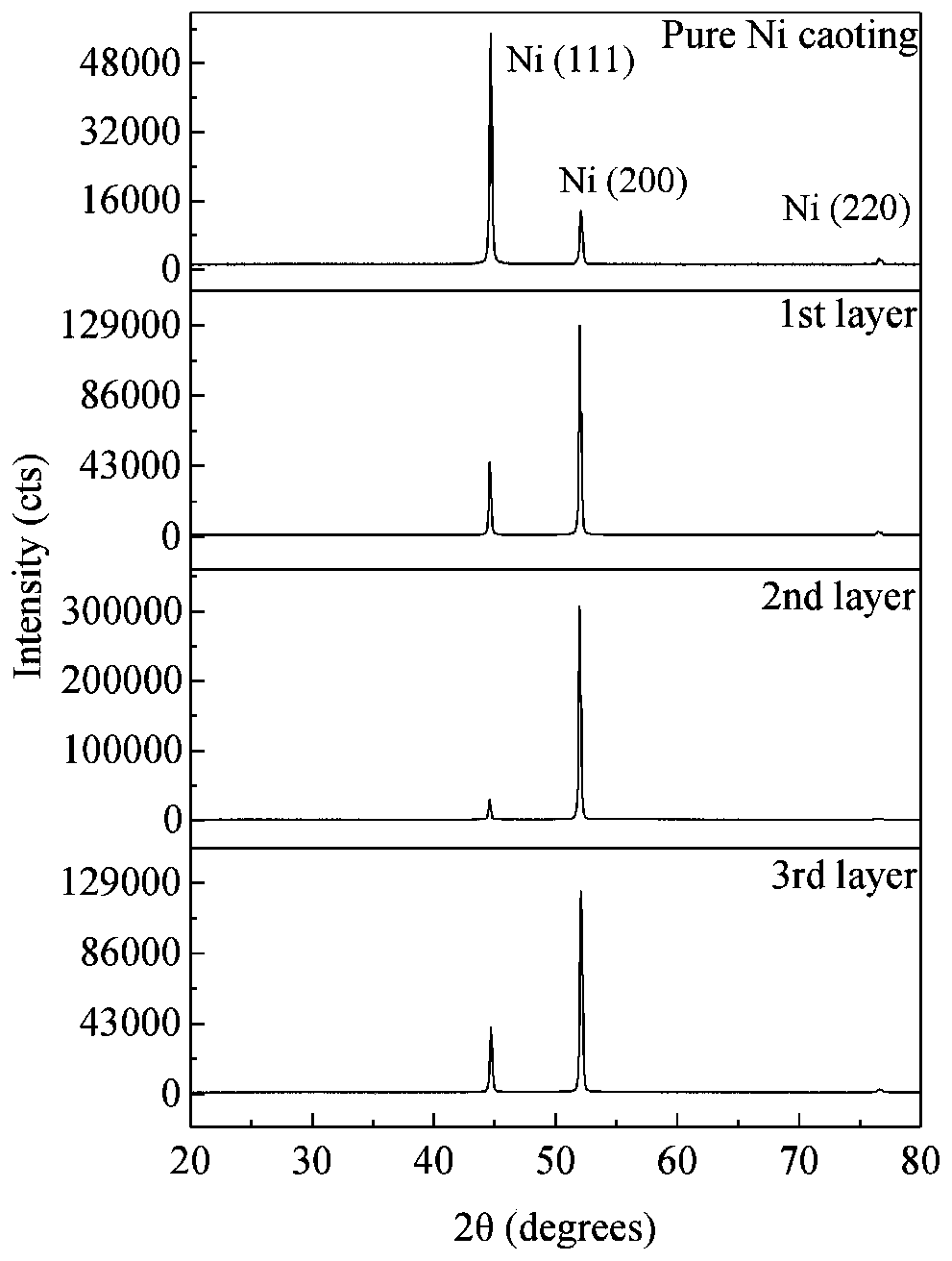

[0053] Wherein, the electroplating includes the first electroplating, the second electroplating and the third electroplating performed in sequence; the duty ratio of the first electroplating is 0.70-0.85, the duty ratio of the second electroplating is 0.55-0.60, and the duty ratio of the third electroplating is 0.70-0.85. The duty cycle is 0.20 ~ 0.40.

[0054] The invention provides a plating solution, which includes graphene oxide. In the present invention, the concentration of graphene oxide in the pl...

Embodiment 1

[0073] Pretreatment of the carbon steel test piece (20# steel, 50mm×25mm×2mm in size): use 150-2000# sandpaper to polish the surface of the carbon steel test piece step by step, and then use a polishing paste with a particle size of W3.5 Polish to the mirror surface and connect the wires; use silica gel to encapsulate the wires and the back of the carbon steel test piece, then use lye to clean and degrease the carbon steel test piece, and use acid to activate and derust the carbon steel test piece;

[0074] Preparation of plating solution: the composition and content of the plating solution are shown in Table 1;

[0075] The composition and content of the plating solution in Table 1

[0076]

[0077] Electroplating the pretreated carbon steel test piece: quickly put the pretreated carbon steel test piece into the constant temperature plating solution, connect the nickel plate (anode) to the anode of the pulse power supply, and put the carbon steel test piece (cathode) Conn...

experiment example 1

[0092] Use a magnetically driven reactor with a volume of 3L produced by Dalian Kemao Experimental Equipment Co., Ltd. to simulate CO 2 The coupon test in the saturated NaCl solution environment (hereinafter referred to as the first simulation environment), specifically the carbon steel test piece containing the gradient coating prepared in Example 1 is soaked in the NaCl solution of 3.5wt% (using the reactor fixture Fix the carbon steel test piece containing the gradient coating), the test temperature is 25°C, keep the exhaust valve of the reaction kettle fully open, make the inside of the reaction kettle under normal pressure conditions, and feed into the NaCl solution in the reaction kettle High-purity CO 2 (purity is 99.999%), until the pH value of NaCl solution does not change, promptly reaches saturated state, carry out hanging test (in the NaCl solution, continuously feed high-purity CO 2 , in order to maintain its saturated state, the duration of the experiment is 6h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com