Die-cast aluminum alloy, preparation method thereof and communication product structural member

A technology of casting aluminum alloy and product structure, which is applied in the field of aluminum alloy materials, can solve the problems of limited use and poor fluidity, and achieve the effects of low production cost, improved fluidity, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Correspondingly, an embodiment of the present invention also provides a method for preparing a die-casting aluminum alloy, including the following steps:

[0063] S10. According to the composition ratio of the die-casting aluminum alloy, first add pure aluminum ingots into the melting furnace, and then add a metal element source that can provide other elemental components other than aluminum for melting after the aluminum ingot is melted;

[0064] S20. Casting after refining and degassing to obtain the die-casting aluminum alloy, the die-casting aluminum alloy includes the following components in mass percentage: magnesium: 0.1%-7%, zinc: 7%-35%, manganese: 0.2%-0.8%, iron: 0.1%-0.7%, titanium and / or zirconium: 0.07%-0.2%, unavoidable impurities ≤ 0.3%, and aluminum.

[0065] In some embodiments, the composition of the die-casting aluminum alloy may further include copper element. In some embodiments, the composition of the die-casting aluminum alloy may further includ...

example 1

[0083] A die-casting aluminum alloy, composed of the following components by mass percentage: silicon: 1.69%, magnesium: 5.62%, zinc: 8.52%, copper: 2.38%, manganese: 0.538%, iron: 0.121%, titanium: 0.104%, Zirconium 0.0015%, unavoidable impurity content ≤ 0.3%, the rest is aluminum.

[0084] The preparation method of the die-casting aluminum alloy in this example includes the following steps:

[0085] According to the composition ratio of the die-casting aluminum alloy, first add pure aluminum ingots into the melting furnace, heat to 730°C-760°C, and keep warm for 30 minutes to melt the aluminum ingots. After all the aluminum ingots are melted, add pure zinc ingots, aluminum silicon Alloy, iron powder, aluminum-manganese alloy, aluminum-copper alloy, aluminum-titanium alloy and aluminum-nickel alloy, then add refining agent and slag, then let it stand for 15 minutes to 25 minutes; then cool down to 700°C-720°C, add For pure magnesium ingots, stir evenly and keep warm for 15-...

example 2-3

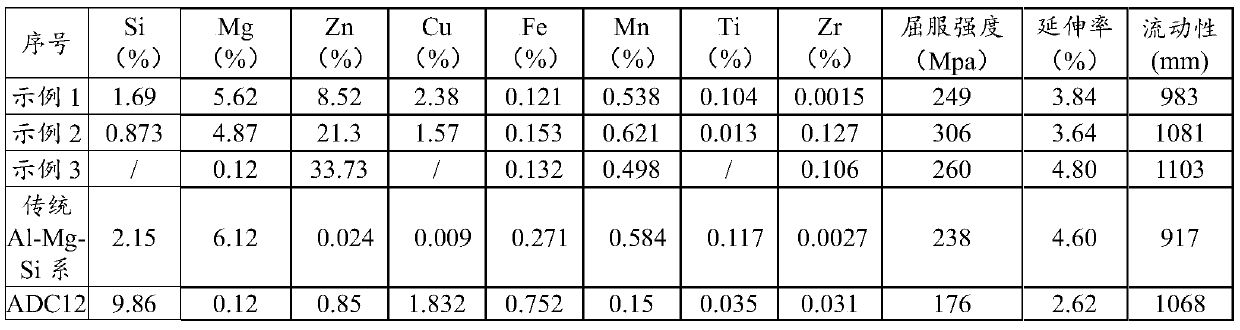

[0087] The specific formula of the die-casting aluminum alloy is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com