Corrosion-resistant metal powder coating material and preparation method thereof

A metal powder and corrosion-resistant technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of short service life, poor durability, and easy corrosion of metal powder coatings, and achieve long service life and enhanced corrosion resistance effect, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of a kind of corrosion-resistant metal powder coating of the present invention comprises the following steps: 1) get resin and solidifying agent, leveling agent, filler, degassing agent, wear-resisting agent, titanium dioxide and / or pigment, mix, At 95-125°C, extrude, tablet, and pulverize to obtain a base powder; 2) Add a bonding agent to the base powder obtained in step 1), stir, and the linear speed of the tip of the stirring paddle is 20- 40m / s, heat up to 55-65°C; 3) Take aluminum powder and pearl powder, preheat to 55-65°C, adjust the linear speed of the paddle tip of the stirring paddle in step 2) to 5-15m / s, At the same time, add preheated aluminum powder and pearl powder, bond for 1-5min, and cool down; 4) in the cooled material obtained in step 3), add a fluidity improver to control the blade tip linear velocity of the stirring paddle No more than 5m / s, mixing, sieving, packaging, and metal powder coatings.

[0029] Specifically, in the...

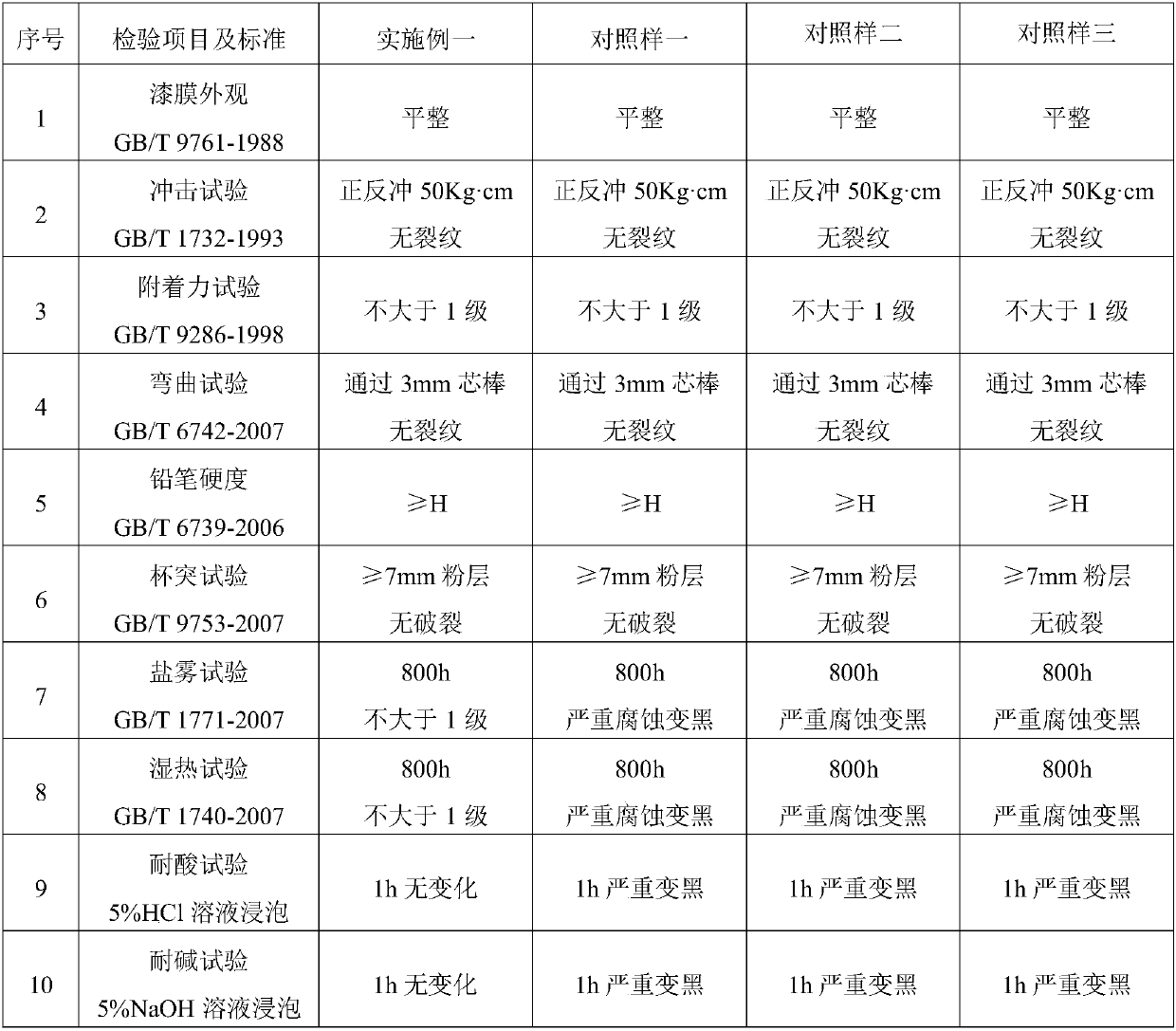

Embodiment 1

[0031] A kind of preparation method of corrosion-resistant metal powder coating of the present invention, comprises the following steps:

[0032] 1) Take the raw materials used for the base powder according to the following parts by weight: polyester resin 35Kg, E-12 epoxy resin 35Kg, filler barium sulfate 16Kg, filler calcium carbonate 10Kg, leveling agent 1Kg, degassing agent benzoin 0.5Kg, poly Ethylene wax powder 0.5Kg, titanium dioxide 2Kg;

[0033] 2) Add the above-mentioned raw materials into the mixer, mix for 5 minutes, put the mixed mixture into the extruder and knead and extrude it at 125°C, then press it into tablets, and grind it with an air cyclone separation mill to obtain the average particle size 30μm powder, i.e. base powder, for later use;

[0034] 3) Weigh the raw materials used in the metal powder coating according to the following parts by weight: 100Kg of the above-mentioned base powder, 2.5Kg of double-coated aluminum powder, 1Kg of pearl powder, 0.5Kg...

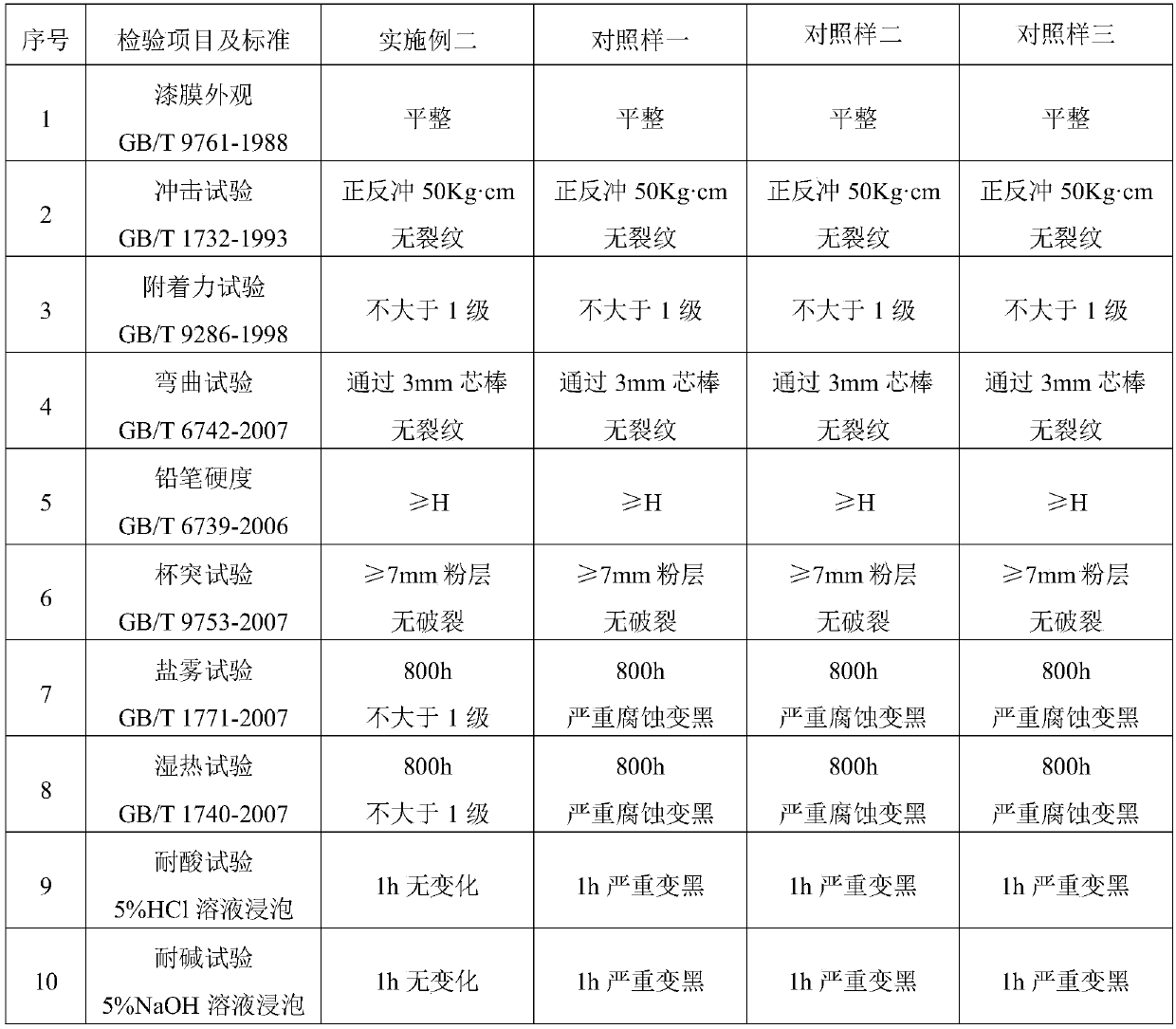

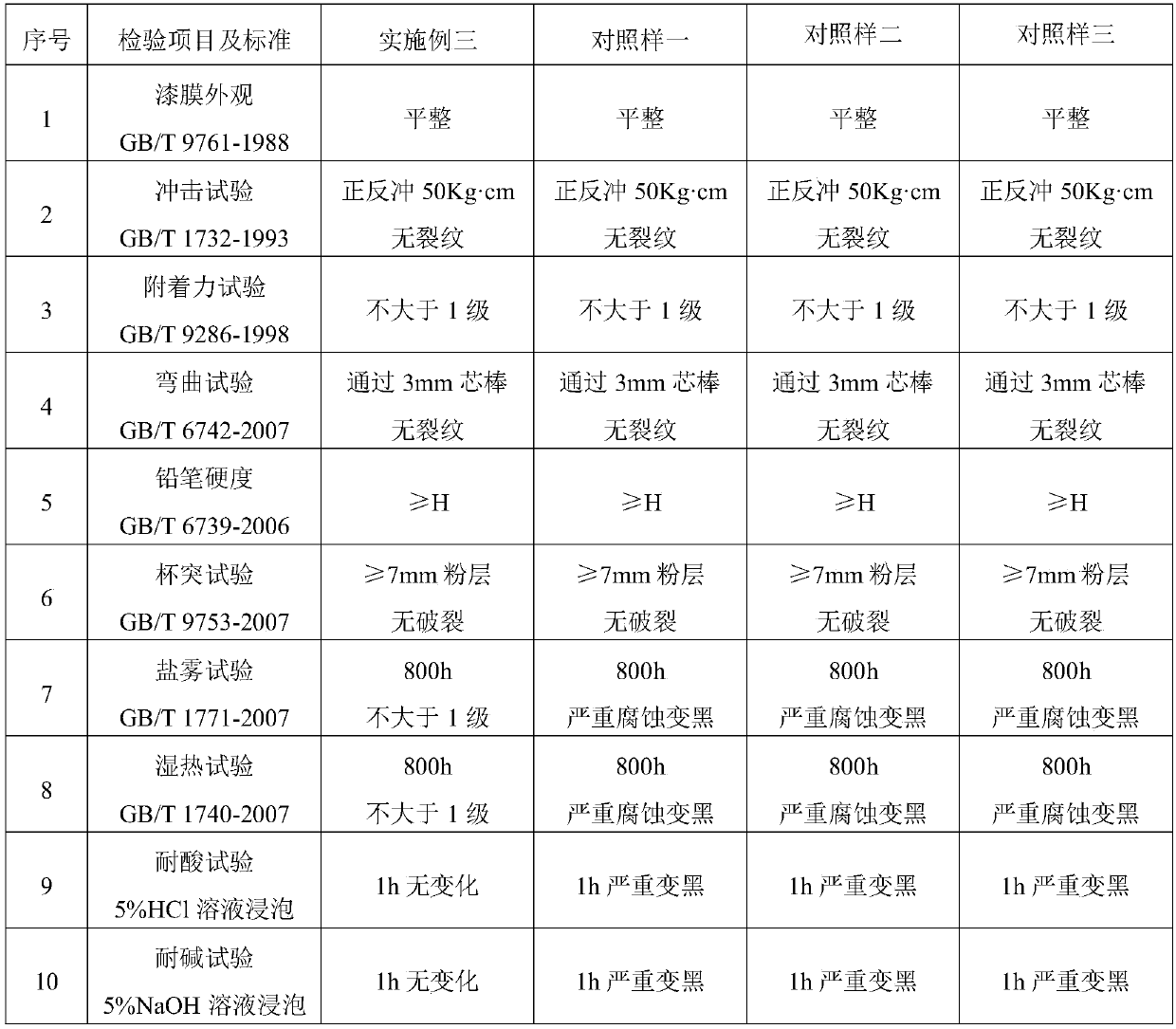

Embodiment 2

[0043] A kind of preparation method of corrosion-resistant metal powder coating of the present invention, comprises the following steps:

[0044] 1) Weigh the raw materials used for the base powder according to the following parts by weight: resin 73Kg, curing agent TGIC 5.5Kg, filler barium sulfate 20Kg, leveling agent 1Kg, degassing agent modified polyamide wax 0.5Kg;

[0045] 2) Add the above-mentioned raw materials into the mixer, mix for 10 minutes, put the mixed mixture into the extruder and knead and extrude it at 100°C, then press it into tablets, crush it, and grind the crushed tablets, Get the base powder and set aside;

[0046] 3) Weigh the raw materials used in the metal powder coating according to the following parts by weight: 100Kg of the above-mentioned base powder, 5kg of double-coated aluminum powder, 0.5Kg of pearl powder, 0.3Kg of polyethylene wax powder, 0.5Kg of polyamide wax powder, fumed silica 0.3Kg; Among them, double-coated aluminum powder is double...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com