Degradable lunch box

A lunch box and modified technology, applied in the field of degradable lunch boxes, can solve problems such as convenience and hazards, and achieve the effects of increasing carbon sequestration capacity, reducing costs, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

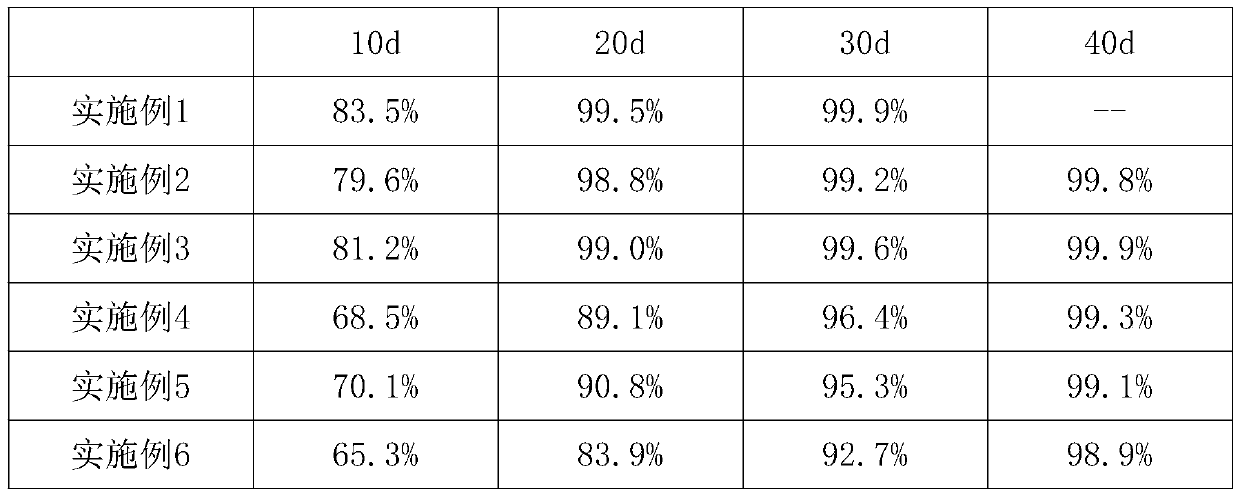

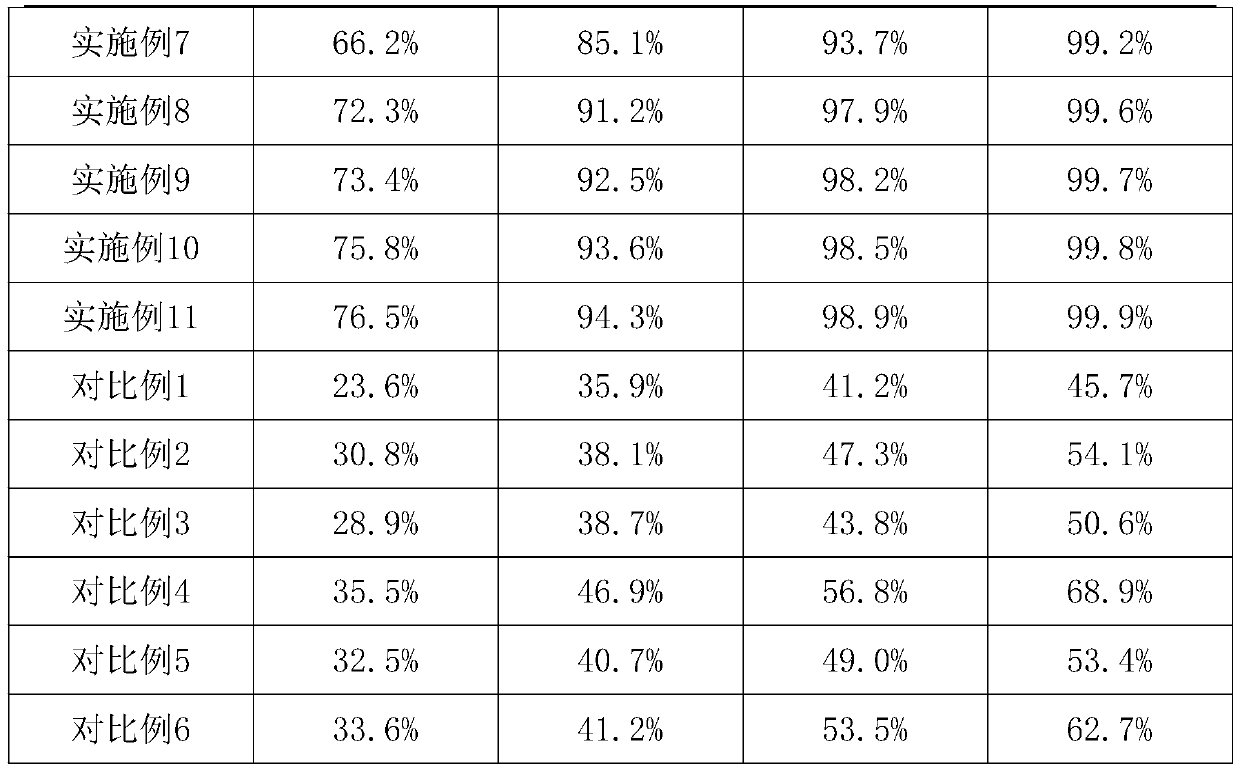

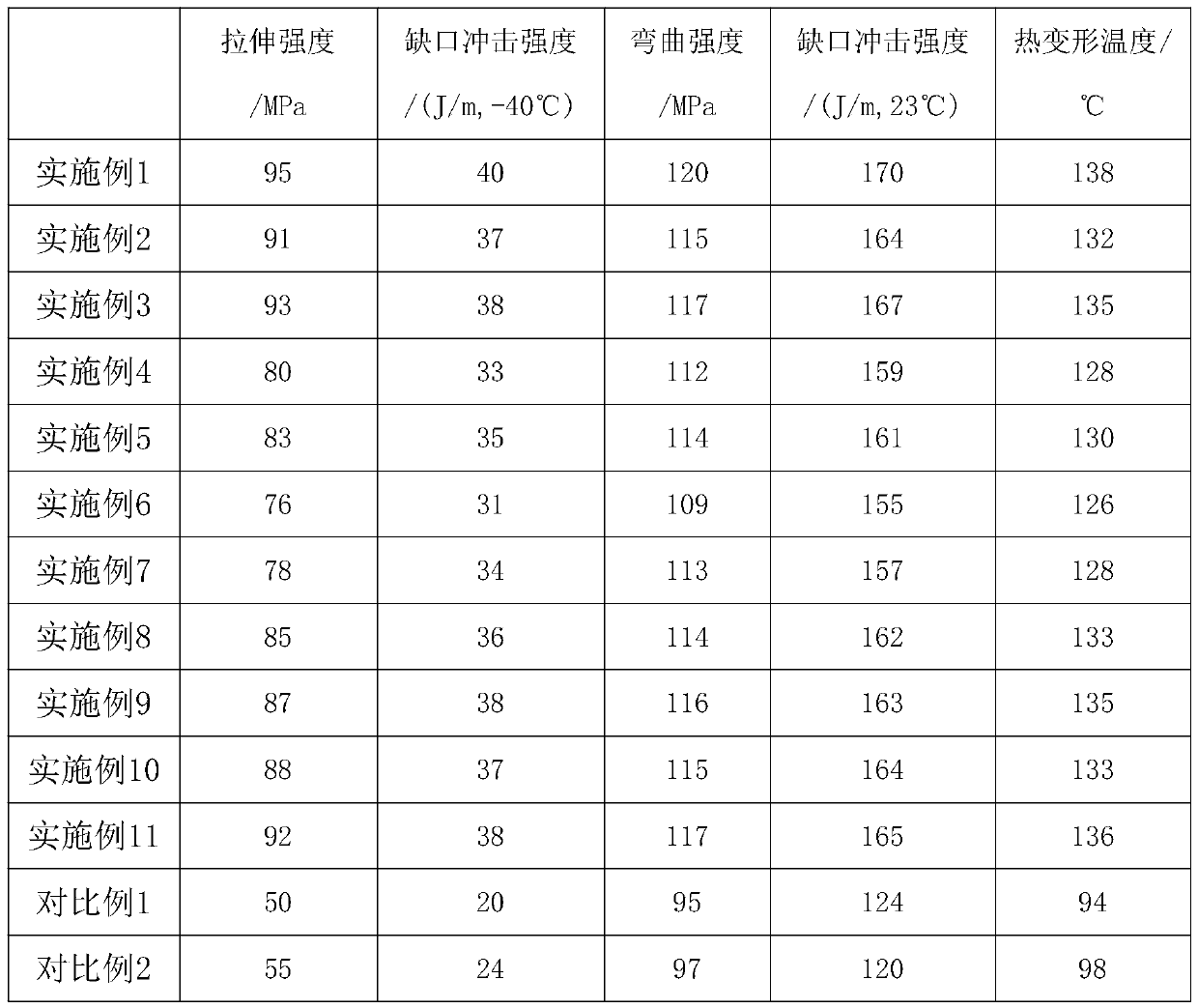

Examples

Embodiment 1

[0030] A degradable lunch box, made of the following raw materials in parts by weight: 45 parts of poly-β-hydroxybutyrate, 25 parts of modified polybutylene succinate, 25 parts of composite biochar, lignocellulose Airgel 15 parts, polylactic acid 15 parts, modified hydroxypropyl acetylated corn starch 8 parts, aluminate coupling agent 6 parts.

[0031] The preparation method of described modified polybutylene succinate is:

[0032] S1. Mix acetate starch and dimethyl sulfoxide with ethanol in a mass ratio of 1:0.3, and react with stirring at 60°C for 2 hours, then let stand for 24 hours to obtain modified acetate starch, the dimethyl sulfoxide Sulfone accounts for the mass of the mixed system;

[0033] S2. Add polybutylene succinate to the above-mentioned modified acetate starch, stir and react at 80°C for 3 hours to make modified polybutylene succinate; wherein, the modified acetate starch, polybutylene succinate The mass ratio of butanediol diacid is 1:2.

[0034] The pre...

Embodiment 2

[0040] This embodiment provides a degradable lunch box. Compared with Embodiment 1, the difference is that it is made of the following raw materials in parts by weight: 40 parts of poly-β-hydroxybutyrate, modified polysuccinic acid 30 parts of butanediol ester, 20 parts of composite biochar, 20 parts of lignocellulose airgel, 20 parts of polylactic acid, 5 parts of modified hydroxypropyl acetylated corn starch, and 5 parts of aluminate coupling agent.

Embodiment 3

[0042] This embodiment provides a degradable lunch box. Compared with Embodiment 1, the difference is that it is made of the following raw materials in parts by weight: 50 parts of poly-β-hydroxybutyrate, modified polysuccinic acid 20 parts of butylene glycol ester, 30 parts of composite biochar, 10 parts of lignocellulose airgel, 10 parts of polylactic acid, 10 parts of modified hydroxypropyl acetylated corn starch, and 8 parts of aluminate coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com