Thermal interface composite material, and preparation method and application thereof

A composite material and thermal interface technology, which is applied in the field of thermal interface composite materials and its preparation, can solve the problems of reduced mechanical properties, difficult processing, high cost, etc., achieve excellent thermal conductivity and mechanical properties, reduce the overall interface thermal resistance, and improve the surface area. The effect of external thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a thermal interface composite material. The specific preparation method includes the following steps:

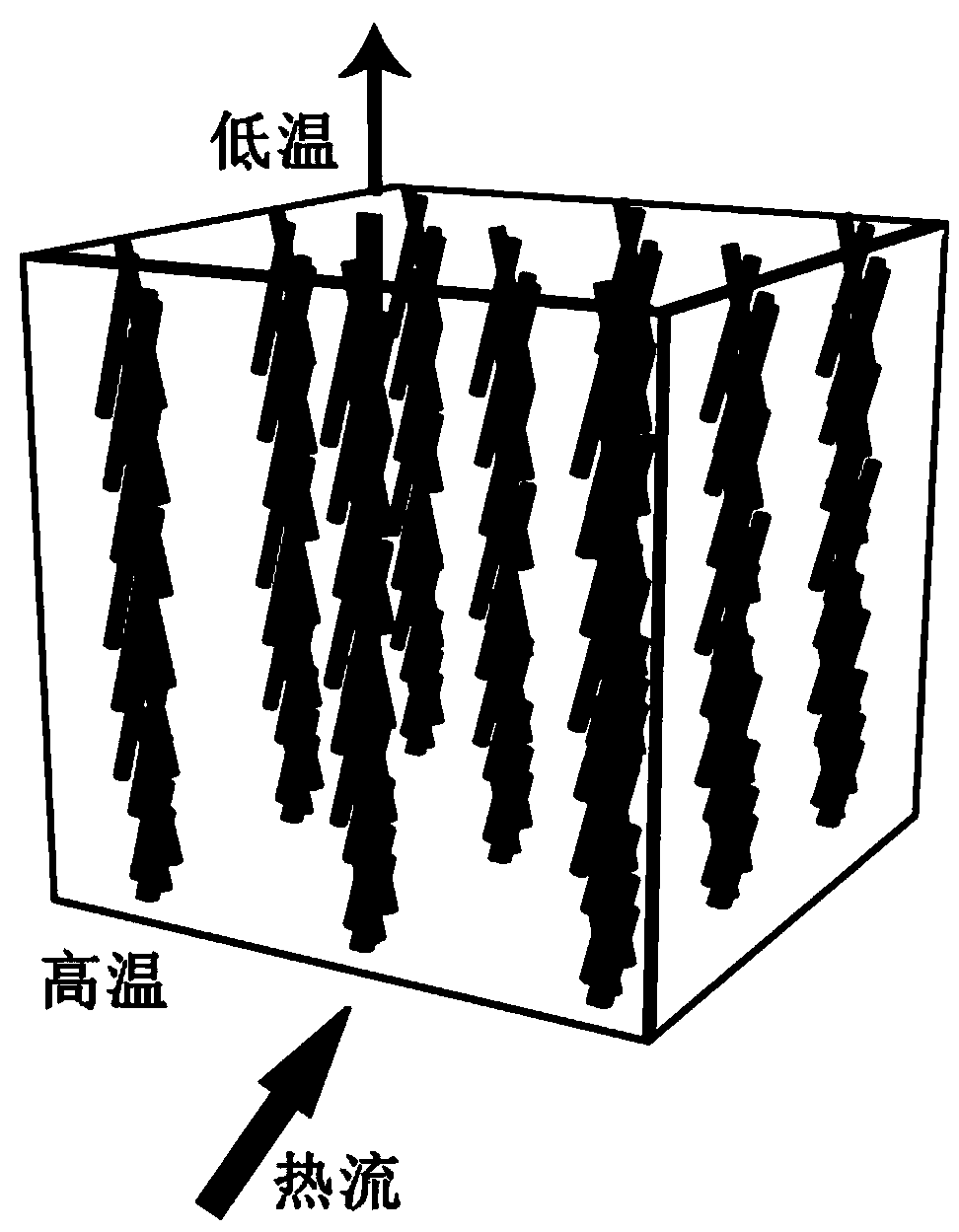

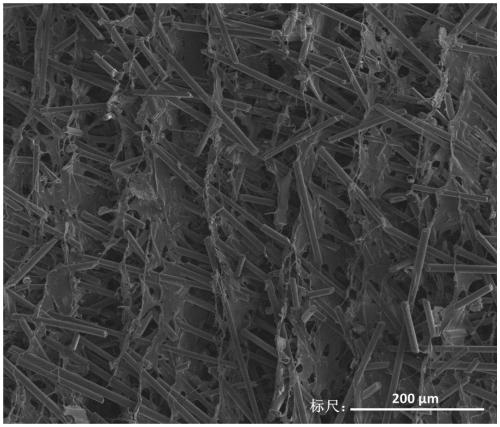

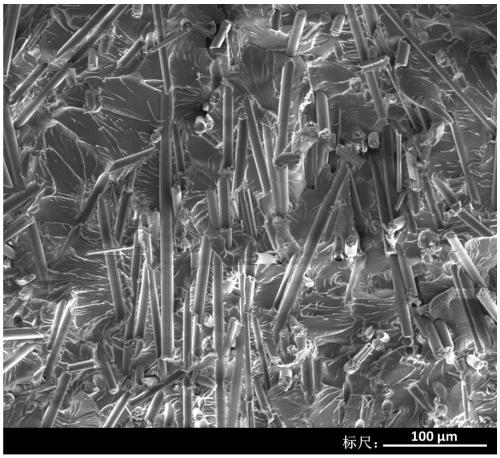

[0068] (1) Preparation of carbon fiber skeleton: Mix 0.8g of carbon fiber powder with surface hydrophilic treatment and an aqueous solution of binder, add appropriate amount of water to make 3mL suspension, stir first with magnet, and then mix under vacuum at 2000rpm After feeding for 20 minutes, a carbon fiber suspension with a volume percentage of carbon fibers of 12% is obtained; then the carbon fiber suspension is frozen with liquid nitrogen and vacuum dried for 24 hours to obtain the carbon fiber skeleton with carbon fibers arranged in a single orientation;

[0069] (2) Preparation of thermal interface composite material: The carbon fiber skeleton obtained in step (1) is completely immersed in epoxy resin, and then placed in a vacuum drying oven, vacuum filtration is carried out at 40°C for 3 hours; followed by gradient heating and curing And ...

Embodiment 2

[0073] This embodiment provides a thermal interface composite material. The specific preparation method includes the following steps:

[0074] (1) Preparation of carbon fiber skeleton: Mix 0.8 g of carbon fiber powder with surface hydrophilic treatment and an aqueous solution of binder, add an appropriate amount of water to make a 3 mL suspension, stir first with magnets, and then mix under vacuum at 1500 rpm. After feeding for 10 minutes, a carbon fiber suspension with a volume percentage of carbon fibers of 12% is obtained; then the carbon fiber suspension is frozen with liquid nitrogen and vacuum dried for 12 hours to obtain the carbon fiber skeleton with carbon fibers arranged in a single orientation;

[0075] (2) Preparation of thermal interface composite material: the carbon fiber skeleton obtained in step (1) is completely immersed in epoxy resin, and then placed in a vacuum drying oven, vacuum filtration is carried out at 30°C for 2 hours; followed by gradient heating and cu...

Embodiment 3

[0077] This embodiment provides a thermal interface composite material. The specific preparation method includes the following steps:

[0078] (1) Preparation of carbon fiber skeleton: Mix 0.8 g of carbon fiber powder with surface hydrophilic treatment and an aqueous binder solution, add a suitable amount of water to prepare 3 mL suspension, stir first with magnets, and then mix in vacuum at 1800 rpm. After 15 minutes, a carbon fiber suspension with a volume percentage of carbon fiber of 12% is obtained; then the carbon fiber suspension is frozen with liquid nitrogen and vacuum dried for 20 hours to obtain the carbon fiber skeleton with carbon fibers arranged in a single orientation;

[0079] (2) Preparation of thermal interface composite material: The carbon fiber skeleton obtained in step (1) is completely immersed in epoxy resin, and then placed in a vacuum drying oven, and vacuum filtration is performed at 35°C for 2.5 hours; then the temperature is gradually increased Curing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com