Method for supporting carbon nitride photocatalyst on surfaces of glass beads

A glass bead and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of difficult large-scale preparation, cumbersome steps, easy to fall off, etc., to achieve controllability and repeatability Good properties, cheap and easy-to-obtain raw materials, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

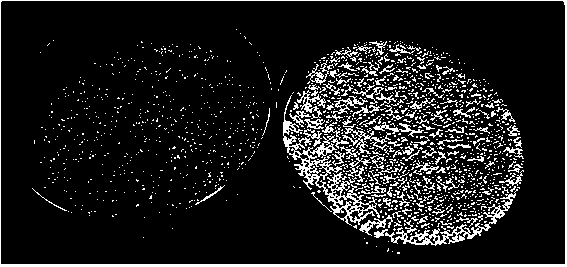

Embodiment 1

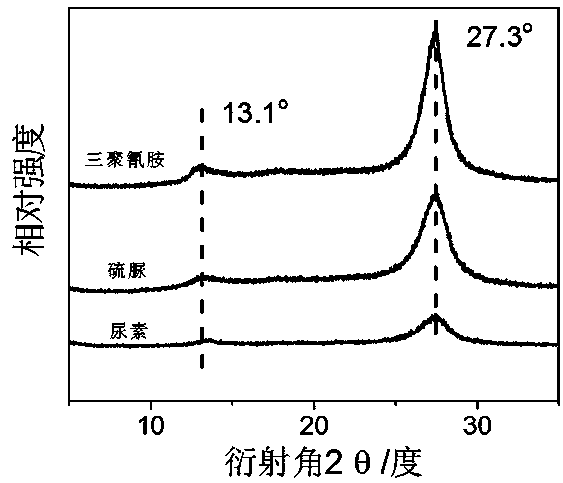

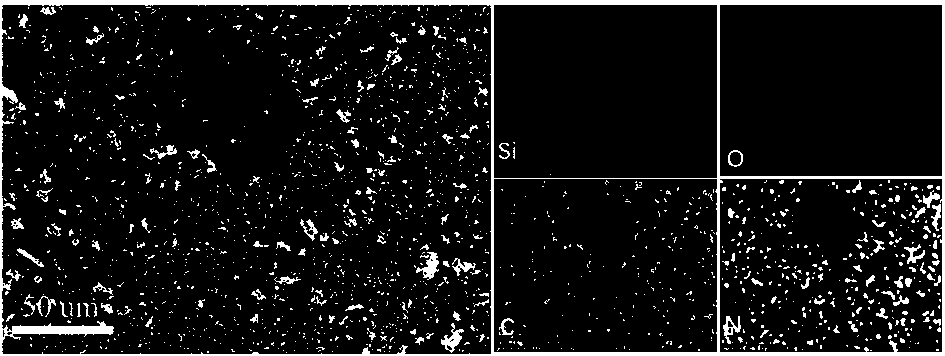

[0018] Put the 1mm glass beads after surface treatment into the newly prepared piranha solution, stir well overnight, after diluting the solution, take out the treated glass beads, put them into anhydrous In toluene solvent (the volume ratio of 3-aminopropyltrimethoxysilane and anhydrous toluene is 1:20), reflux at 110°C for 12 hours, separate, wash with dichloromethane and ethanol, and dry in a vacuum drying oven Dry, then mix with equal mass of urea evenly, place in an air muffle furnace, heat up to 550°C at 3°C / min, after heat treatment for 2h, cool down to room temperature naturally, then place in deionized water to rinse off the surface of the glass beads The excess carbon nitride material is used to obtain glass beads of carbon nitride photocatalysts uniformly loaded on the surface.

Embodiment 2

[0020] Put the 1 mm glass beads after surface treatment into the newly prepared piranha solution, and stir overnight. After diluting the solution, take out the treated glass beads and put them into anhydrous In toluene solvent (the volume ratio of 3-aminopropyltrimethoxysilane and anhydrous toluene is 1:10), reflux at 110°C for 12 hours, separate, wash with dichloromethane and ethanol, and dry in a vacuum drying oven Dry it, then mix it evenly with equal mass of dicyandiamide, put it in an air muffle furnace, raise the temperature to 600°C at 5°C / min, and after heat treatment for 2h, cool it down to room temperature naturally, then rinse it off in deionized water The excess carbon nitride material on the surface of the glass beads is used to obtain glass beads with carbon nitride photocatalysts evenly loaded on the surface.

Embodiment 3

[0022] Put the 2 mm glass beads after surface treatment into the newly prepared piranha solution, and stir overnight. After diluting the solution, take out the treated glass beads and put them in anhydrous In toluene solvent (the volume ratio of 3-aminopropyltrimethoxysilane and anhydrous toluene is 1:15), reflux at 110°C for 12 hours, separate, wash with dichloromethane and ethanol, and dry in a vacuum drying oven Dry, then mix with equal mass of urea, place in an air muffle furnace, heat up to 550°C at 2°C / min, after heat treatment for 2 hours, cool to room temperature naturally, then place in deionized water to wash off the surface of the glass beads The excess carbon nitride material is used to obtain glass beads of carbon nitride photocatalysts uniformly loaded on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com