Preparation method of ruthenium doped LDH/rGO composite material and application of composite material in hydrogen evolution reactions

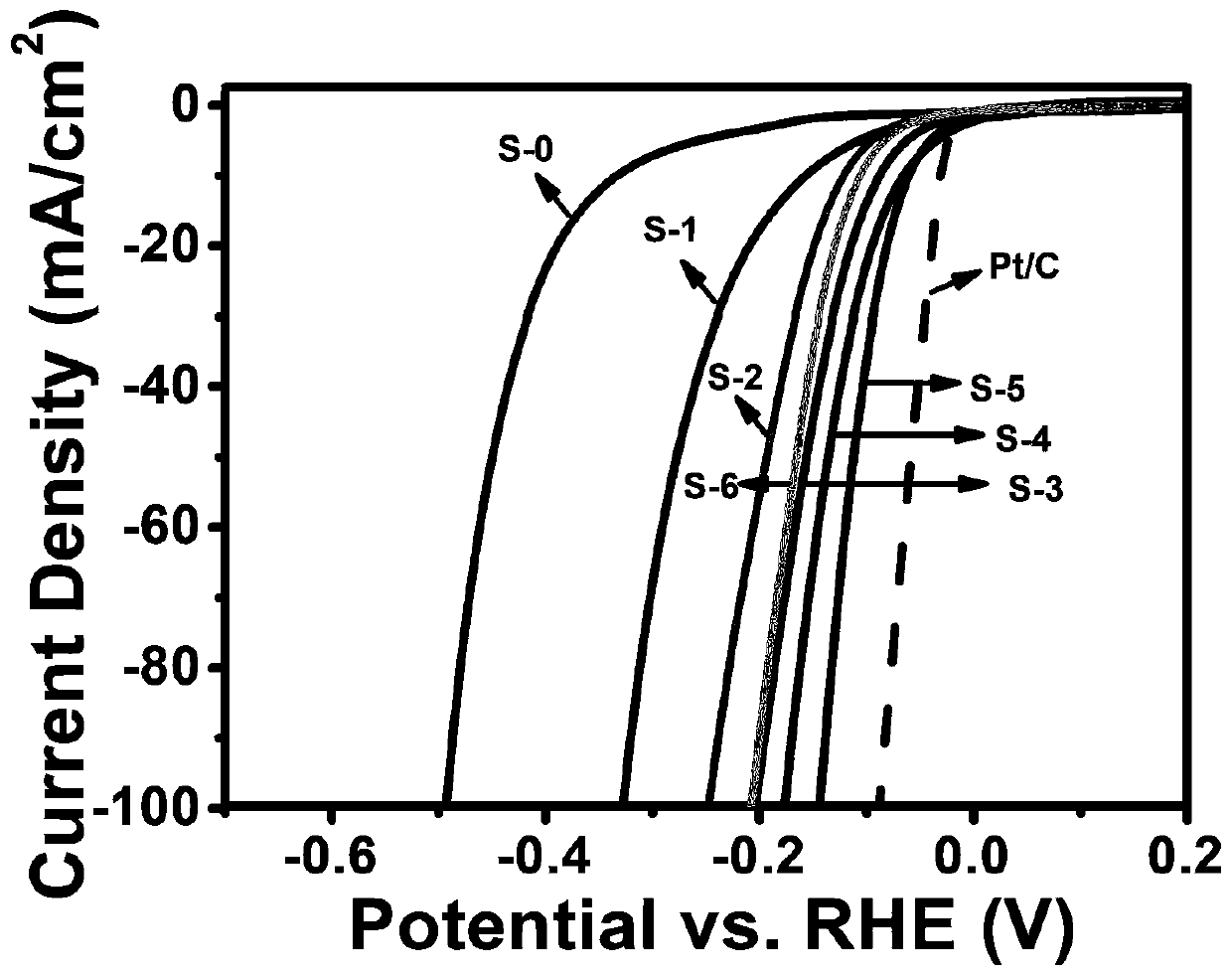

A composite material and hydrogen evolution reaction technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of large overpotential, poor conductivity, and the impact of hydrogen production catalyst catalysis Conversion rate and other issues to achieve the effect of improving hydrogen evolution performance, enhancing electrical conductivity, and accelerating water electrolysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Add 3.0g graphite powder to concentrated H 2 SO 4 with concentrated H 3 PO 4 In the mixed solution with a volume ratio of 9:1, add 18.0g KMnO 4 Slowly added to the above mixed solution, warmed up to 50°C and stirred for 12h; added 400mL of ice to cool to room temperature, then added 3mL of 30% H 2 o 2 , filtered, the filtrate was centrifuged (4000rpm, 10 minutes), after removing the supernatant, washed with water (200mL), 30% HCl aqueous solution (200mL) and ethanol (200mL) successively, and finally the product was washed with deionized water until neutral , freeze-dried to obtain graphene oxide.

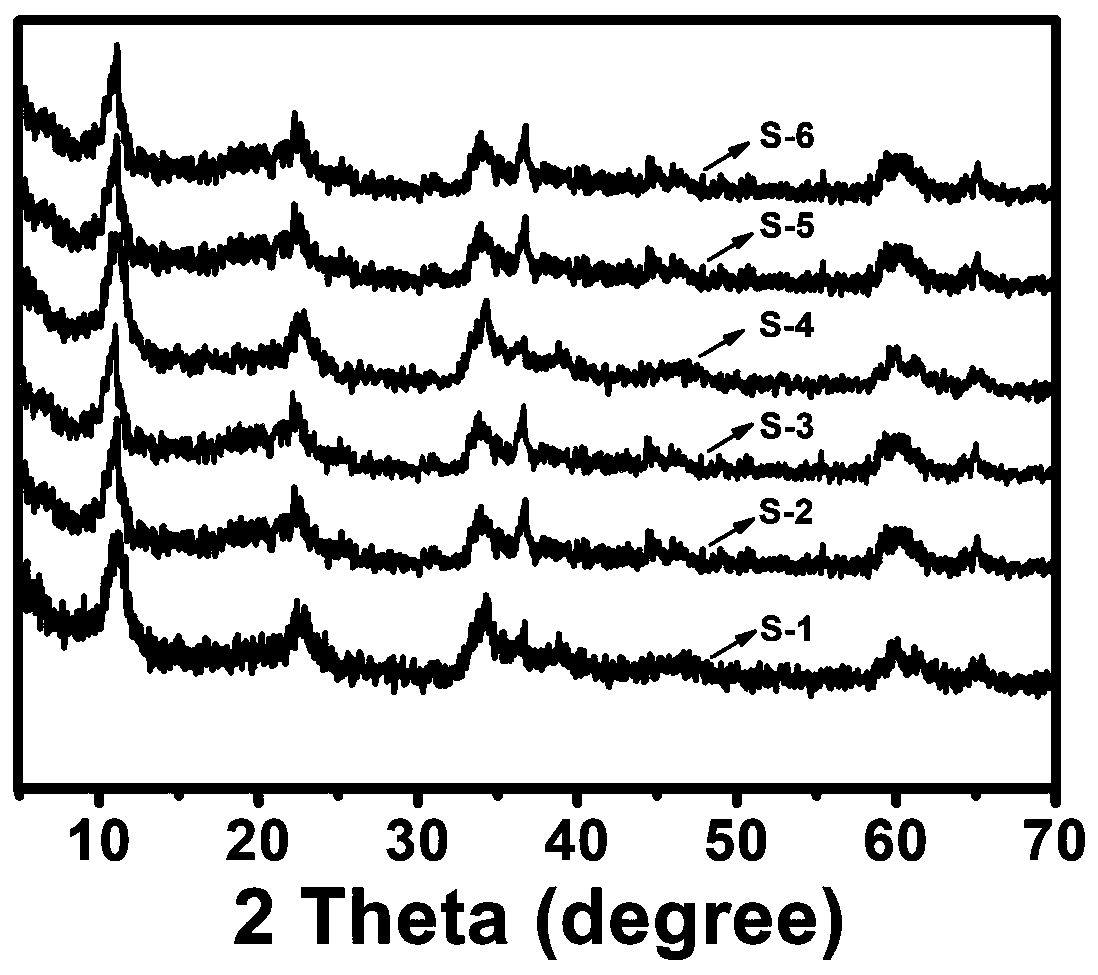

[0021] 2. Weigh 300mg of GO obtained in step 1 and disperse it in 20.0ml of 0.25M Co(NO 3 ) 2 Sonicate the clarified solution for 12 hours, add 1.5, 3, 5, 7, 9, 11 mL of RuCl with a concentration of 12.238 mg / mL 3 Aqueous solution, sonicated for 12h, then quickly added to 100ml of 0.125M ammonia solution continuously fed with pure oxygen, stirred at 40°C for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com