Perovskite light-emitting diode based on pre-spin coating FABr and preparation method thereof

A light-emitting diode, perovskite technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as reducing industrial production costs, expensive and disadvantageous crown ether materials, and achieving less material usage , The preparation cycle is short, and the brightness is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

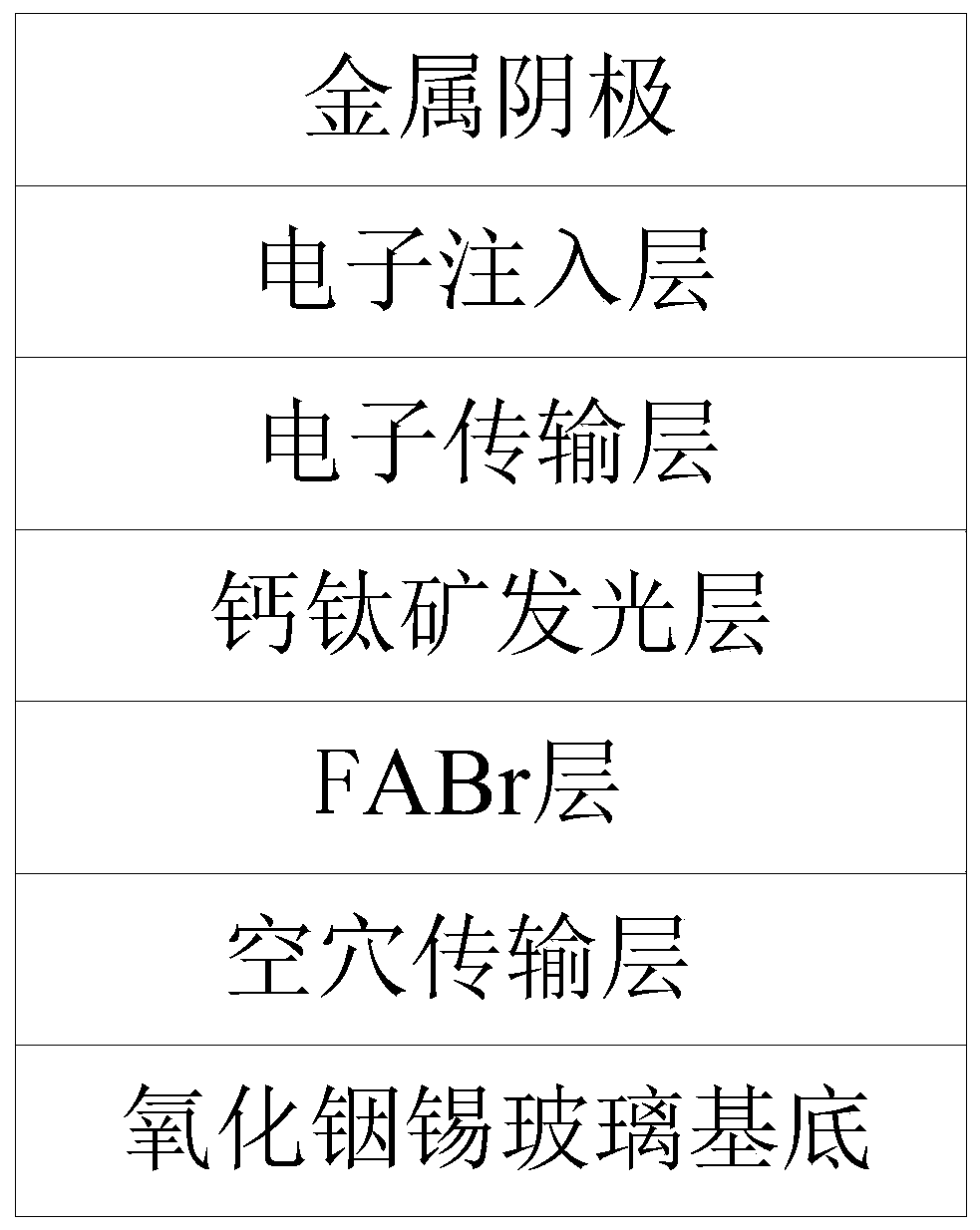

[0049] Perovskite light-emitting diode based on pre-spin-coated FABr, including indium tin oxide glass substrate, hole transport layer, FABr layer, perovskite light-emitting layer, electron transport layer, electron injection layer and metal cathode layered sequentially from bottom to top ;

[0050] The hole transport layer is prepared from polyethylenedioxythiophene:polystyrenesulfonic acid (PEDOT:PSS), and the film thickness is 45nm;

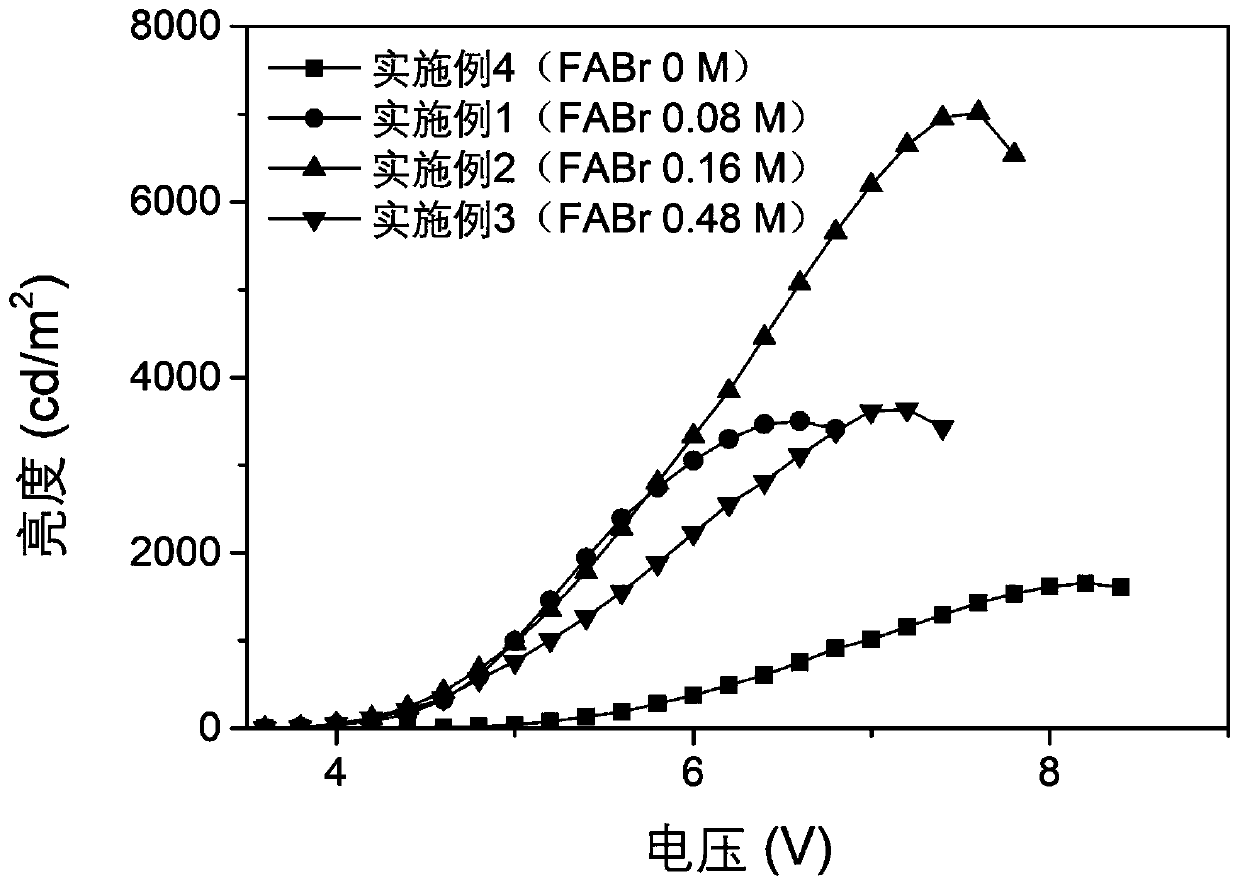

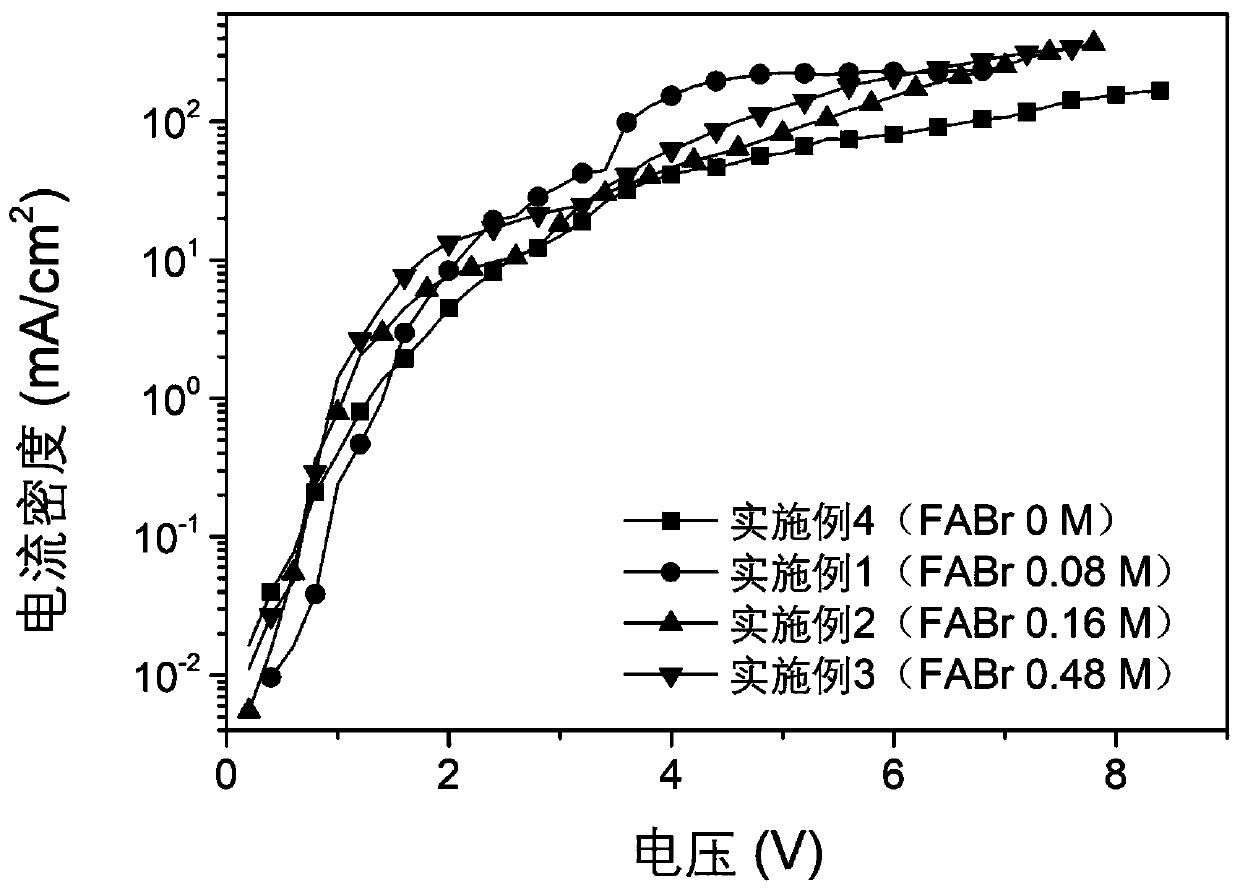

[0051] The FABr layer is prepared by spinning a FABr solution with a solution concentration of 0.08mol / L after 10mg FABr is dissolved in 1mL DMSO;

[0052] The perovskite luminescent layer is prepared by adding an anti-solvent dropwise during the spin coating process of the perovskite precursor solution, and the perovskite precursor solution is composed of 0.1468g PbBr 2 , 0.0336g MABr and 0.0404g PEABr were dissolved in 1mL DMSO; Pb in the obtained perovskite precursor 2+ The concentration is 0.5mol / L;

[0053] The electron transport layer...

specific Embodiment 2

[0063] Perovskite light-emitting diode based on pre-spin-coated FABr, including indium tin oxide glass substrate, hole transport layer, FABr layer, perovskite light-emitting layer, electron transport layer, electron injection layer and metal cathode layered sequentially from bottom to top ;

[0064] The hole transport layer is prepared from polyethylenedioxythiophene:polystyrenesulfonic acid (PEDOT:PSS), and the film thickness is 45nm;

[0065] The FABr layer is prepared by spinning a FABr solution with a solution concentration of 0.16mol / L after 20mg FABr is dissolved in 1mL DMSO;

[0066] The perovskite luminescent layer is prepared by adding an anti-solvent dropwise during the spin coating process of the perovskite precursor solution, and the perovskite precursor solution is composed of 0.1468g PbBr 2 , 0.0336g MABr and 0.0404g PEABr were dissolved in 1mL DMSO; Pb in the obtained perovskite precursor 2+ The concentration is 0.5mol / L;

[0067] The electron transport layer...

specific Embodiment 3

[0077] Perovskite light-emitting diode based on pre-spin-coated FABr, including indium tin oxide glass substrate, hole transport layer, FABr layer, perovskite light-emitting layer, electron transport layer, electron injection layer and metal cathode layered sequentially from bottom to top ;

[0078] The hole transport layer is prepared from polyethylenedioxythiophene:polystyrenesulfonic acid (PEDOT:PSS), and the film thickness is 45nm;

[0079] The FABr layer is prepared by spin coating with a solution concentration of 0.48mol / L after 60mg FABr is dissolved in 1mL DMSO;

[0080] The perovskite luminescent layer is prepared by adding an anti-solvent dropwise during the spin coating process of the perovskite precursor solution, and the perovskite precursor solution is composed of 0.1468g PbBr 2 , 0.0336g MABr and 0.0404g PEABr were dissolved in 1mL DMSO; Pb in the obtained perovskite precursor 2+ The concentration is 0.5mol / L;

[0081] The electron transport layer is prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com