A kind of qled device reinforced by composite structure and its preparation method

A composite structure and device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as QLED light trapping, improve light-emitting capacity, overcome excessive air refractive index difference, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

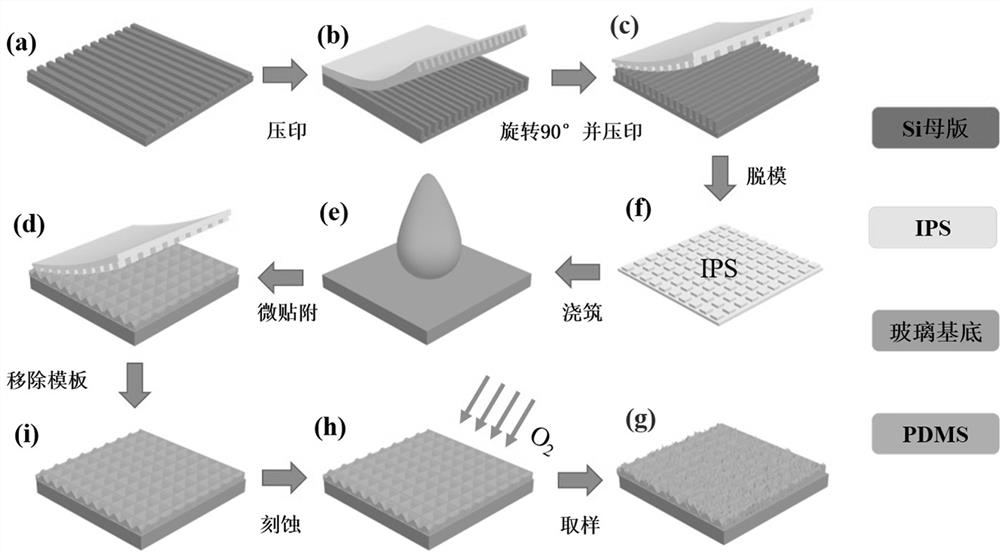

[0038] A method for preparing QLEDs enhanced by a composite structure, such as figure 1 shown, including the following steps:

[0039] (1) Spin-coat PEDOT:PSS layer, TFB layer, QDs layer and ZnO layer on the ITO side of the ITO glass substrate in turn, and then evaporate Al electrodes on the ZnO layer, and use curing glue to cure the Al electrodes to obtain the encapsulated QLED devices;

[0040] (2) The IPS template is a circle with a diameter of 8 cm. Cut it into four square structures with a size of 2.5 * 2.5 cm for use. Remove the protective layer on the IPS template and attach the side with the protective layer removed to the Si Then put the IPS template and the Si master into the center of the stage of the nanoimprinting instrument, and cover a layer of UV film on the IPS template as a protective layer, send the stage above the lifting platform and then lower it hatch, start the program for the first nanoimprinting, set the temperature of the first nanoimprinting at 15...

Embodiment 2

[0063] A method for preparing QLEDs enhanced by a composite structure, such as figure 1 shown, including the following steps:

[0064] (1) Spin-coat PEDOT:PSS layer, TFB layer, QDs layer and ZnO layer on the ITO side of the ITO glass substrate in turn, and then evaporate Al electrodes on the ZnO layer, and use curing glue to cure the Al electrodes to obtain the encapsulated QLED devices;

[0065] (2) The IPS template is a circle with a diameter of 8 cm. Cut it into four square structures with a size of 2.5 * 2.5 cm for use. Remove the protective layer on the IPS template and attach the side with the protective layer removed to the Si Then put the IPS template and the Si master into the center of the stage of the nanoimprinting instrument, and cover a layer of UV film on the IPS template as a protective layer, send the stage above the lifting platform and then lower it door, start the program for the first nanoimprinting, set the temperature of the first nanoimprinting at 145...

Embodiment 3

[0079] A method for preparing QLEDs enhanced by a composite structure, such as figure 1 shown, including the following steps:

[0080] (1) Spin-coat PEDOT:PSS layer, TFB layer, QDs layer and ZnO layer on the ITO side of the ITO glass substrate in turn, and then evaporate Al electrodes on the ZnO layer, and use curing glue to cure the Al electrodes to obtain the encapsulated QLED devices;

[0081] (2) The IPS template is a circle with a diameter of 8 cm. Cut it into four square structures with a size of 2.5 * 2.5 cm for use. Remove the protective layer on the IPS template and attach the side with the protective layer removed to the Si Then put the IPS template and the Si master into the center of the stage of the nanoimprinting instrument, and cover a layer of UV film on the IPS template as a protective layer, send the stage above the lifting platform and then lower it door, start the program for the first nanoimprinting, set the temperature of the first nanoimprinting at 155...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com