Alkali adding-based waste rubber processing method and system

A technology of alkali treatment and lye, applied in sustainable manufacturing/processing, textile/flexible product manufacturing, fiber chemical characteristics, etc., can solve the problems of high cost, unfavorable environmental protection, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

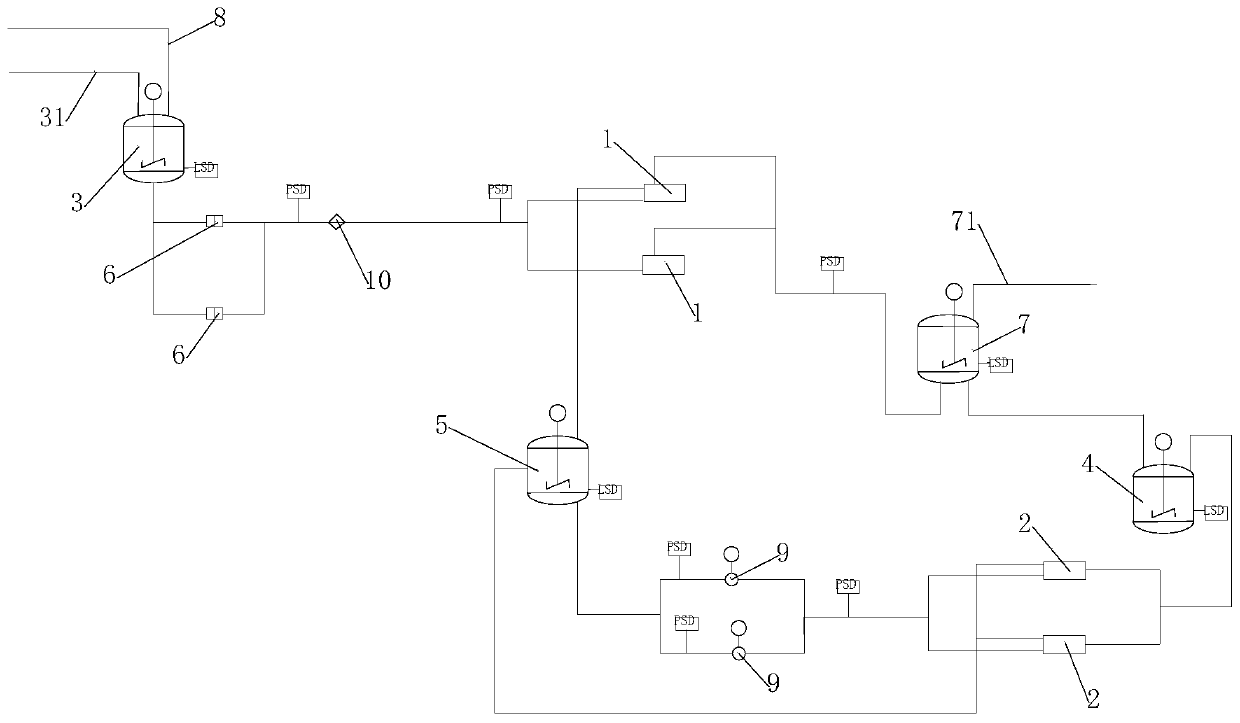

Method used

Image

Examples

Embodiment 1

[0037] A kind of method of processing waste rubber based on adding alkali of the present embodiment specifically comprises the following steps:

[0038] S1, input the waste glue into the waste glue tank 3 through the lye delivery pipeline and stir to obtain the self-assembled dispersion Ⅰ. Fiber blocks, short fibers and flocs of different lengths can be seen under the microscope, and the glue is turbid;

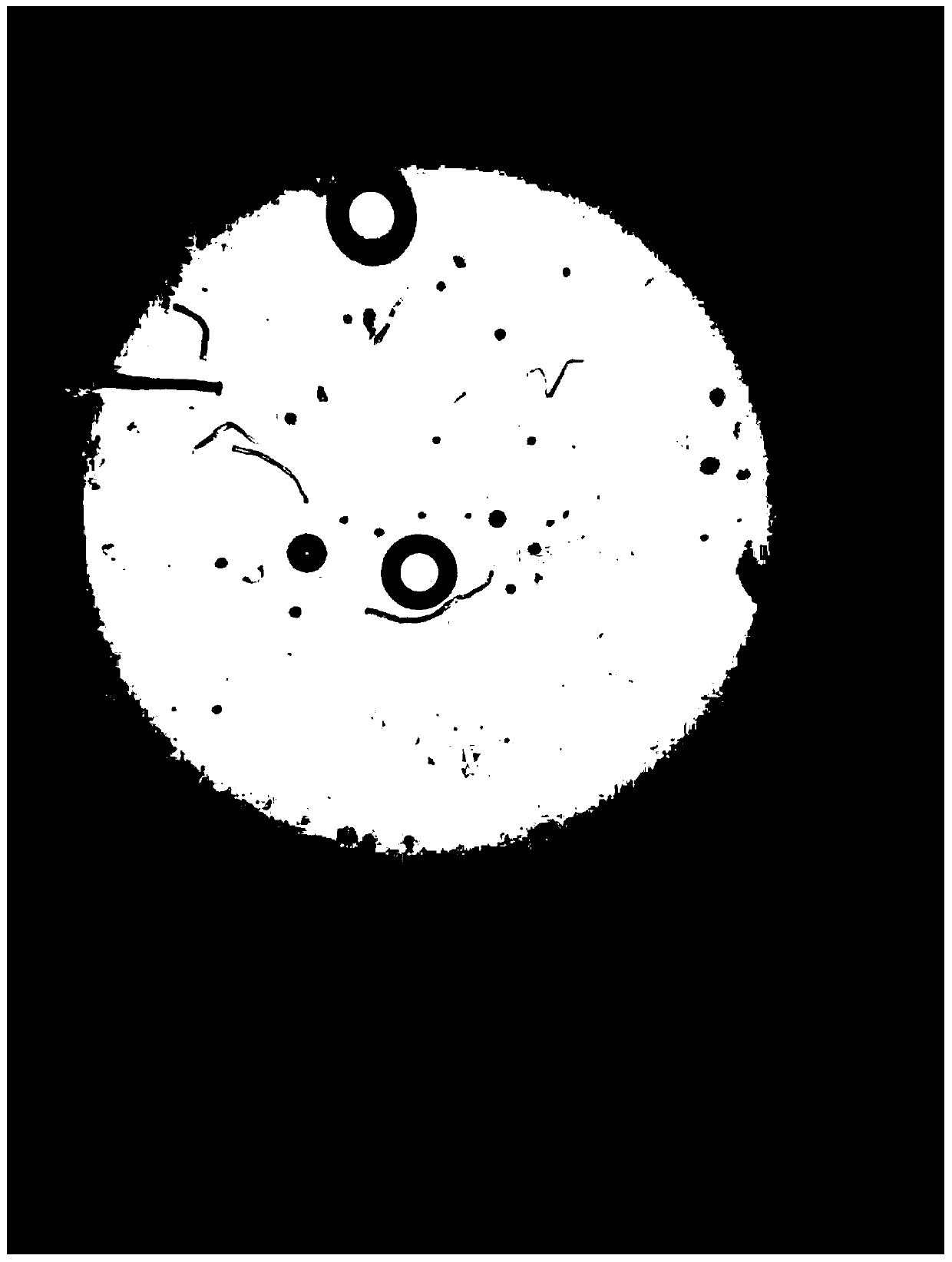

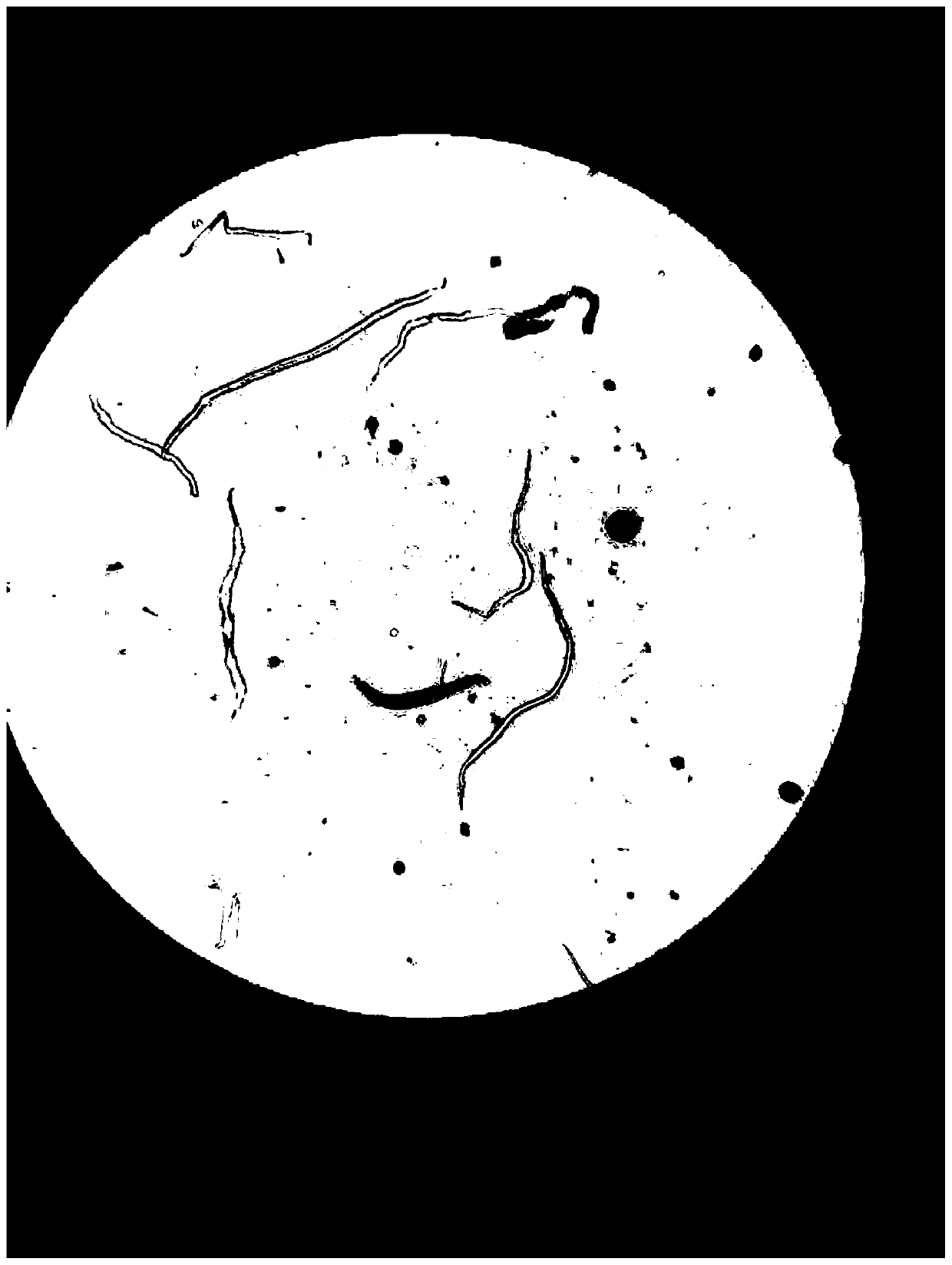

[0039] S2, adding high-concentration lye to the self-assembly dispersion I and stirring to obtain the self-assembly dispersion II, observing under a microscope that the fiber blocks, short fibers of different lengths and flocs dissolve rapidly, and the glue is clear; figure 2 as shown, figure 2 It is the breaking condition of cellulose under high-concentration lye (above 140g / L); image 3 It is the condition of cellulose breakage under low concentration of lye (below 140g / L). Compared figure 2 and image 3 It can be seen that the use of high-concentration lye can make ...

specific Embodiment approach 1

[0046] A method for treating waste rubber based on adding alkali, comprising the following steps:

[0047] S1, input the waste rubber into the waste rubber tank and stir, the stirring speed is 20rmp, and the stirring time is 15min, to obtain the self-assembly dispersion I;

[0048] S2, adding a sodium hydroxide solution with a concentration of 450g / L to the self-assembly dispersion I and stirring, the stirring speed is 20rmp, and the stirring time is 15min to obtain the self-assembly dispersion II; the self-assembly dispersion The concentration of II is 140g / L. The volume ratio of the self-assembly dispersion I to the lye is 3:0.8.

[0049] S3, filtering the self-assembly dispersion II.

specific Embodiment approach 2

[0051] A method for treating waste rubber based on adding alkali, comprising the following steps:

[0052] S1, input the waste rubber into the waste rubber tank and stir, the stirring speed is 22rmp, and the stirring time is 20min, to obtain the self-assembly dispersion I;

[0053] S2, adding a sodium hydroxide solution with a concentration of 430g / L to the self-assembly dispersion I and stirring, the stirring speed is 22rmp, and the stirring time is 20min to obtain the self-assembly dispersion II; the self-assembly dispersion The concentration of II is 150g / L. The volume ratio of the self-assembly dispersion I to the lye is 3:0.9.

[0054] S3, filtering the self-assembly dispersion II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com