Corrosion-resistant high strength and toughness magnesium alloy tubular product and preparation process

A tough magnesium alloy and preparation process technology, applied in the field of corrosion-resistant high-strength and tough magnesium alloy pipes and preparation processes, can solve the problems of difficult plastic processing, poor deformation ability, etc., and achieve good corrosion resistance, uniform corrosion, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

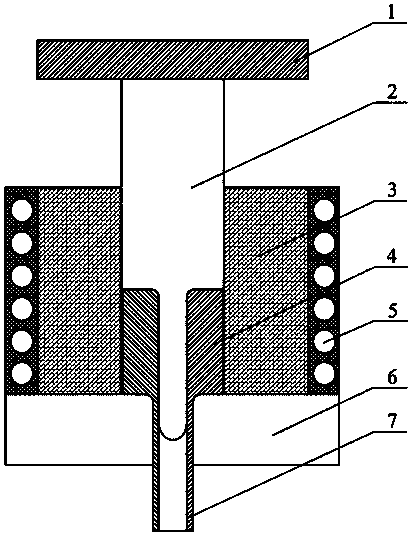

Image

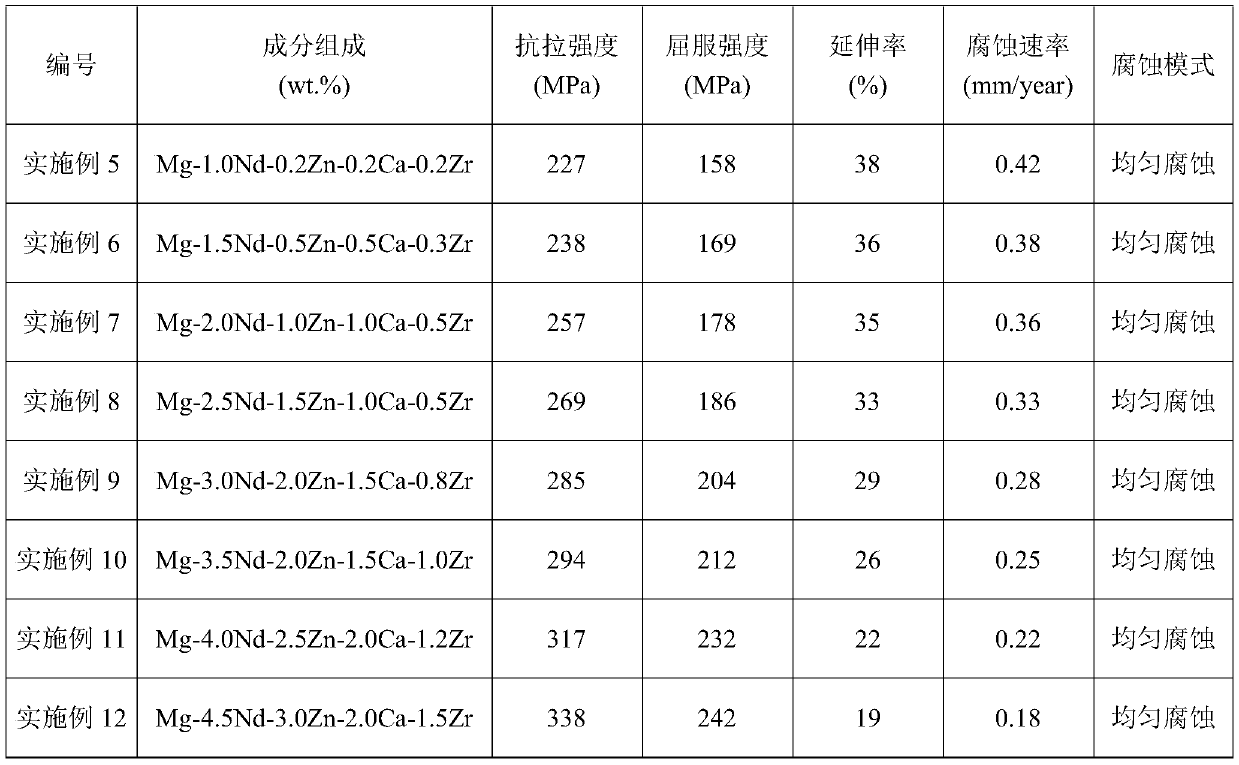

Examples

Embodiment 1

[0067] This example provides a corrosion-resistant high-strength magnesium alloy pipe, including the following components in mass percentage:

[0068] Nd 1.0%, Zn 0.1%, Ca 0.1%, Zr 0.1%, the balance is Mg, the total amount of impurity elements in the corrosion-resistant high-toughness magnesium alloy pipe <0.05%.

Embodiment 2

[0070] This example provides a corrosion-resistant high-strength magnesium alloy pipe, including the following components in mass percentage:

[0071] Nd 6.0%, Zn 5.0%, Ca 5.0%, Zr 4.0%, the balance is Mg, the total amount of impurity elements in the corrosion-resistant high-strength magnesium alloy pipe <0.05%.

Embodiment 3

[0073] This example provides a corrosion-resistant high-strength magnesium alloy pipe, including the following components in mass percentage:

[0074] Nd 3.0%, Zn 2.5%, Ca 2.5%, Zr 2.0%, the balance is Mg, the total amount of impurity elements in the corrosion-resistant high-toughness magnesium alloy pipe <0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com