Cathode electrophoretic paint resin with high salt spray resistance and preparation method thereof

A cathodic electrophoresis and salt spray resistance technology, which is applied in the direction of electrophoretic coatings, coatings, etc., can solve the problems of not being able to achieve high salt spray resistance, so as to improve the salt spray resistance of the paint film, improve the quality, and high salt spray resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

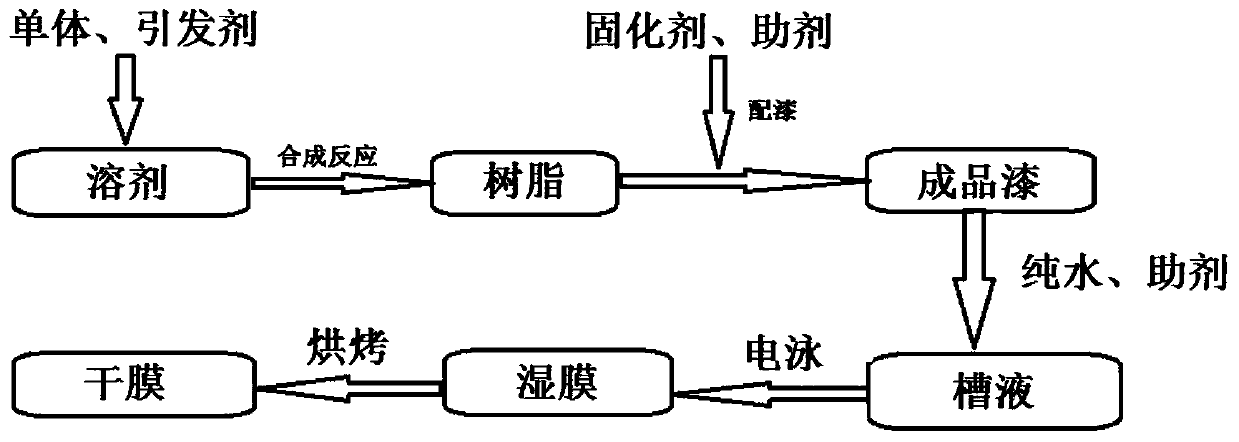

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0016] A kind of preparation method of cathodic electrophoretic paint resin of high salt spray resistance performance of the present invention, in its preferred embodiment, raw material comprises solvent, initiator, monomer and neutralizing agent; Said monomer comprises: methacrylic acid Methyl ester, styrene, hydroxyethyl methacrylate, dimethylaminoethyl methacrylate, butyl acrylate, phosphate monomer; the initiator includes: azobisisobutyronitrile; the solvent includes: isobutyronitrile One or more mixtures of propanol, ethylene glycol ether, ethylene glycol butyl ether, ethyl acetate, butyl acetate, ethylene glycol ether acetate and n-butanol; the neutralizer includes: formic acid, acetic acid and one of lactic acid;

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com