Current overload protection method

A current overload and current technology, applied in the field of circuits, can solve problems such as the failure of bimetallic strips to be heated and deformed normally, the failure of overload protectors, and double-chip bouncing fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] A current overload protection method, the steps of which are:

[0074] (1) Overload stage;

[0075] S1: Whether the current of the induction circuit of the protector body 100 is overloaded;

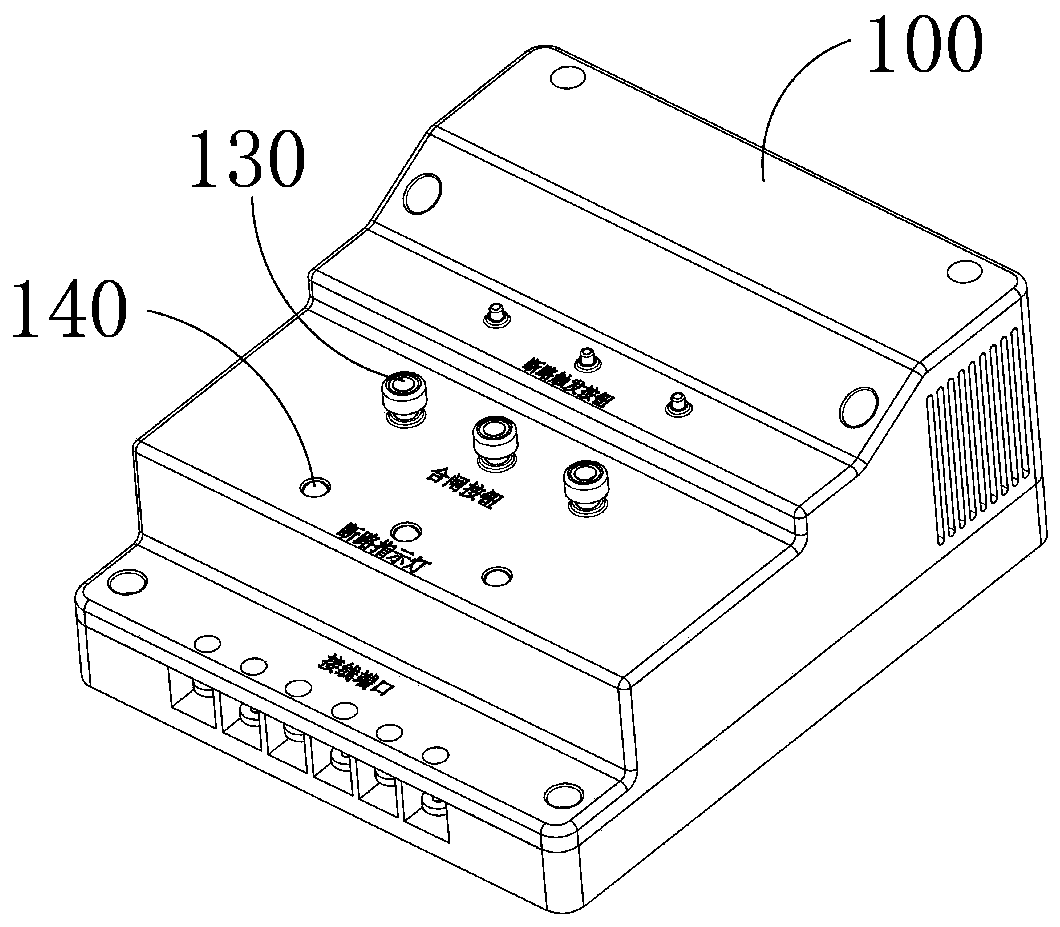

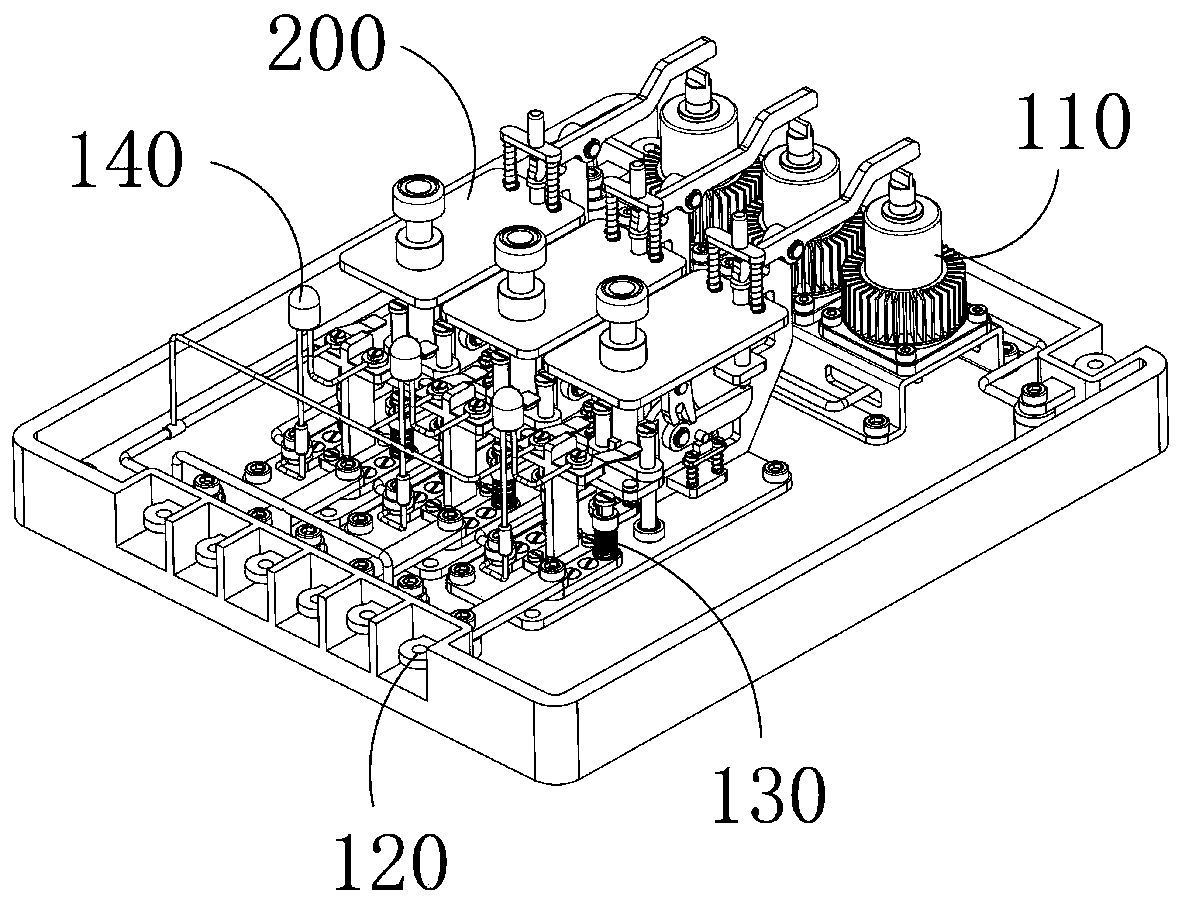

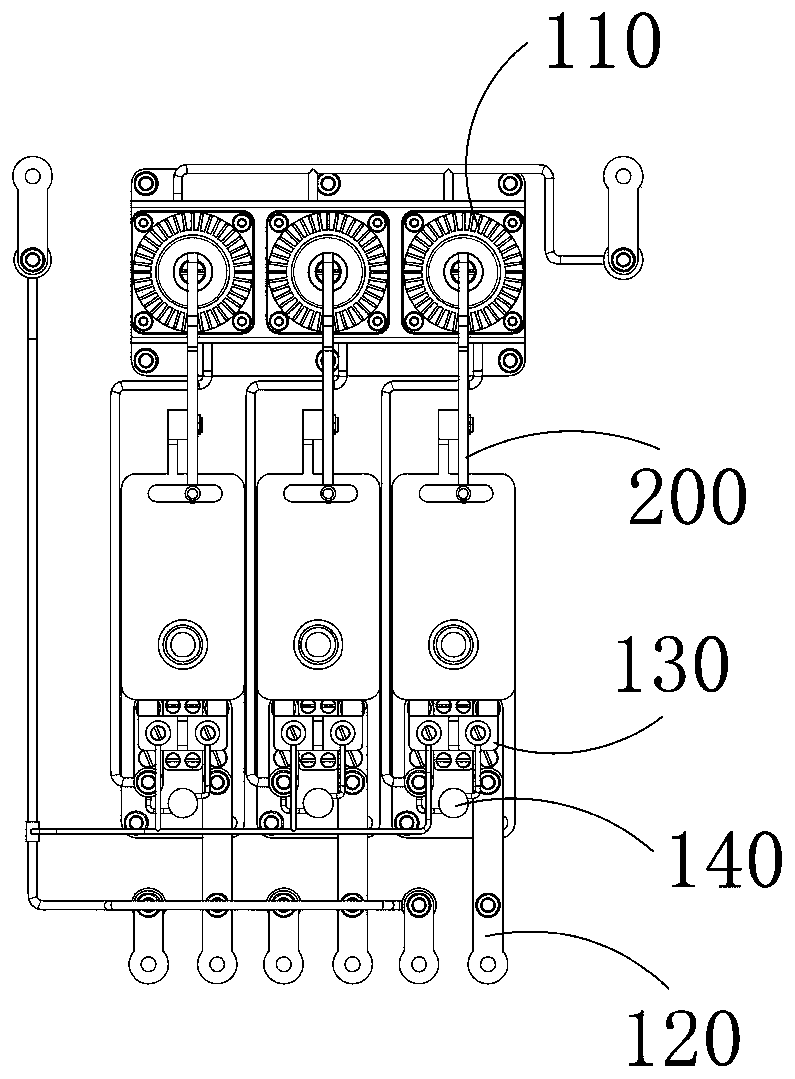

[0076] The protector body 100 includes a horizontally placed installation case, and a circuit wiring mechanism 120 and a protection mechanism are installed in the installation casing. The circuit connection mechanism 120 is used for circuit wiring between power supplies, electrical equipment, and protection mechanisms. The protection mechanism includes an overload sensing member 110 and a circuit connecting member 130. The overload sensing member 110 is used to automatically sense whether the circuit current is overloaded. The circuit connecting member 130 is used to control the circuit flow between the power supply current and the electrical equipment, and the circuit connecting member 130 It can be divided into the closed state that enables the current to be smoothly transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com