A transmission system for aerodynamics

A transmission system and aviation power technology, applied to transmission parts, automatic clutches, clutches, etc., can solve problems such as limited transmission torque, wear, and large shaft tension, and achieve good economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

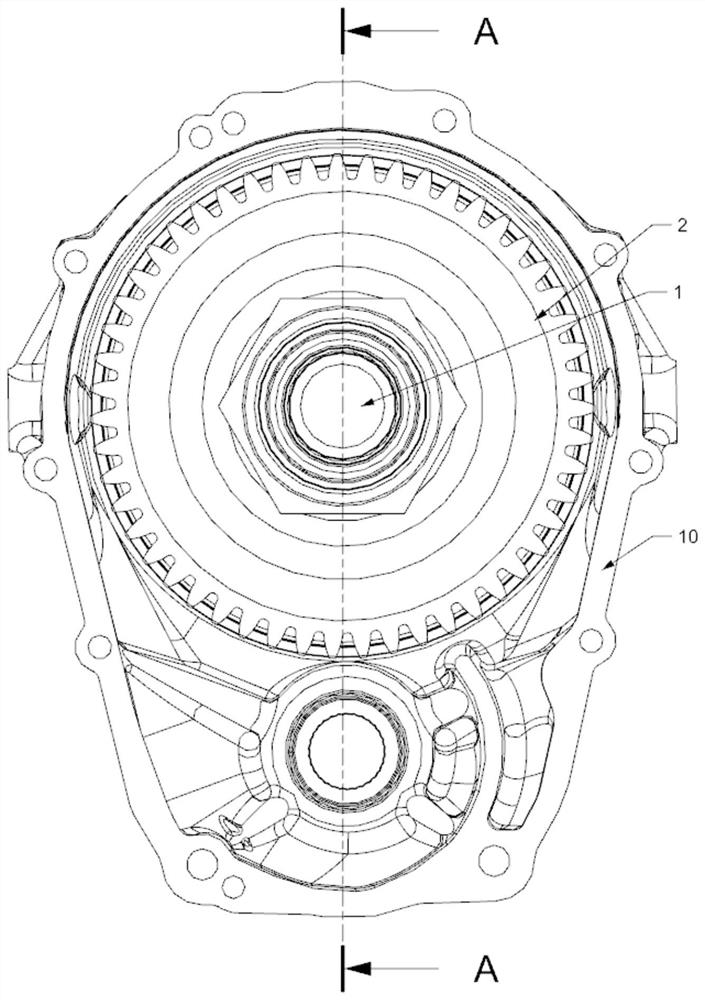

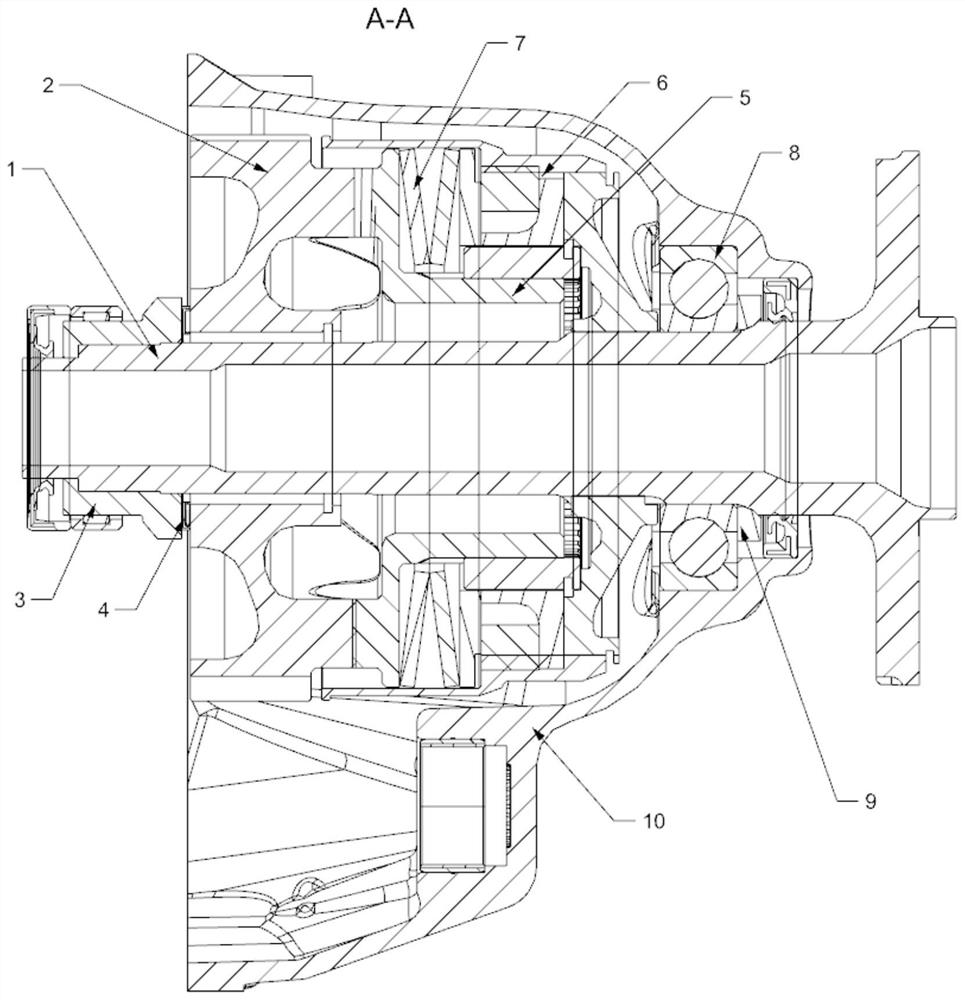

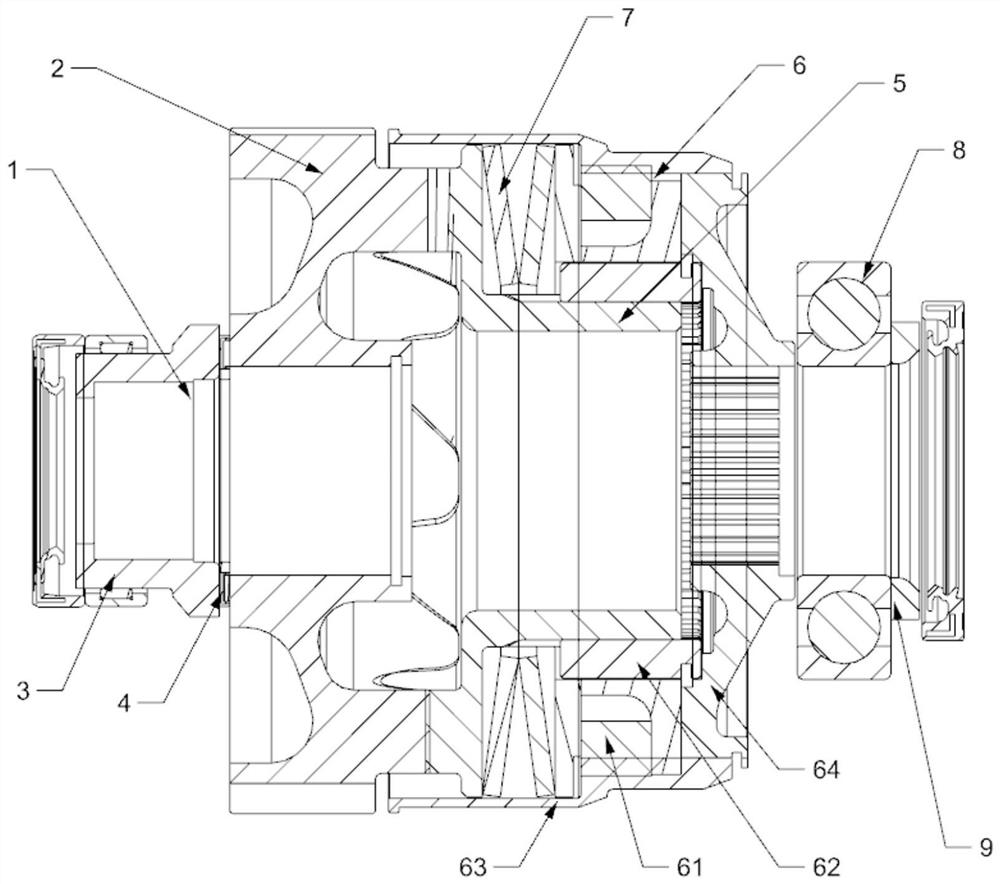

[0031] Example: such as Figure 1-6 As shown, this embodiment provides a transmission system for aerodynamics, for example, it can be used on aircraft such as drones and helicopters. Including a transmission shaft 1, the input end of the transmission shaft is vacantly sleeved with a driven gear 2 and one end of the driven gear is axially limited, the other end of the transmission shaft is used to connect a rotating member, and the rotating member Usually a propeller.

[0032] In this embodiment, the end of the driven gear away from the propeller is limited by the bushing 3 , and a needle bearing 4 is arranged between the end face of the bushing and the end face of the driven gear. The driven gear is meshed with the driving gear in the transmission case, and the driving gear is connected to the power output shaft of the aeroengine, and the engine transmits power to the driving gear, and then to the driven gear.

[0033] The other end of the driven gear is in transmission conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com