Mechanical torque speed reduction structure

A technology of deceleration structure and mechanical torque, applied in the field of mechanical torque deceleration mechanism and mechanical torque deceleration structure, can solve problems such as overload damage to mechanical parts, and achieve the effect of overcoming overload damage to mechanical parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

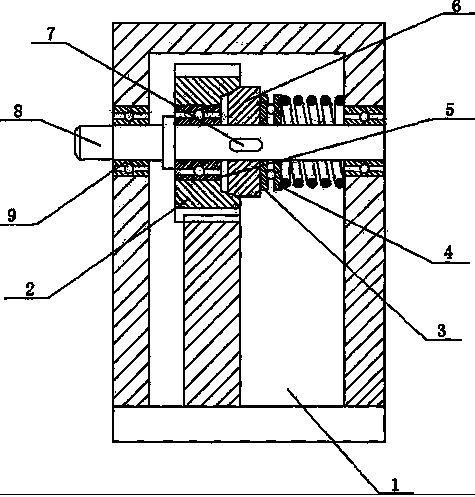

[0009] The torque reduction mechanism has a non-stage gear (2), the non-stage gear (2) is installed on the output shaft inside the reduction gear box (1) through the double-position bearing (5), and the torque friction disc (6) passes through the positioning key (7) Installed on the transmission output shaft (8) on one side of the unstaged gear (2); there are two parallel bearings (3), and the two parallel bearings (3) are installed on the transmission output shaft (8), one of which is (3) lean against the left side of the torque friction disc (6), and the other parallel bearing (3) leans against the inner right side of the reduction gearbox (1) box, and the two parallel bearings (3) A butterfly spring (4) is installed, and the butterfly spring (4) combines the torque friction disc (6) with the unstaged gear (2) through one of the parallel bearings (3), and the other parallel bearing (3) ) on the Belleville spring (4) is installed on the reduction gearbox (1) through the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com