Boron-nitrogen lubricant composition and its preparation method and the preparation of micro-quantity lubricant by the combination

A lubricant composition and micro-lubricant technology, applied in the field of lubrication, can solve the problems of affecting the health of operators, using a large amount of lubricant, wasting resources, etc., and achieve good degradable performance, good biodegradable performance, and lubricating performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Weigh 564.92 g (1 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them into a stirrer, stir and heat to 120° C., and fully react for 1 hour.

[0036] Step 2: Weigh 30.92 g (0.5 mol) of boric acid and add it to the stirrer of Step 1, keep it at 120 ° C for 3 hours, add 10 g of hydroxyethylethanolamine and continue stirring for about 1 hour to filter, which is the boron nitrogen type lubricating oil composition.

[0037] Step 3: Weigh 290 g of polyethylene glycol (PEG200) into Step 2 and keep it at 120° C. for 2 hours to form the boron nitrogen lubricant composition.

[0038] The boron-nitrogen lubricant composition prepared in Example 1 can be directly used as a micro-quantity lubricant, and it can be directly used in a micro-quantity lubrication device after adding 3 times of water and stirring to make it transparent.

[0039] The above-mentioned boron-nitrogen lubricant composition was subjected to a four-ball extreme pressure test using the ...

Embodiment 2

[0041] Step 1: Weigh 282.46 g (0.5 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them into a stirrer, stir and heat to 100° C., and fully react for 2 hours.

[0042] Step 2: Weigh 20.61g (1 / 3mol) of boric acid and add it to the stirrer of step 1, keep it at 100°C for 4 hours, add 8g of hydroxyethylethanolamine and continue stirring for about 1 hour to filter, which is boron nitrogen type lubricating oil composition .

[0043] Step 3: Weigh 280 g of polyethylene glycol (PEG300) and add it to Step 2, keep it at 100° C. for 3 hours to react, and then the boron-nitrogen lubricant composition is obtained.

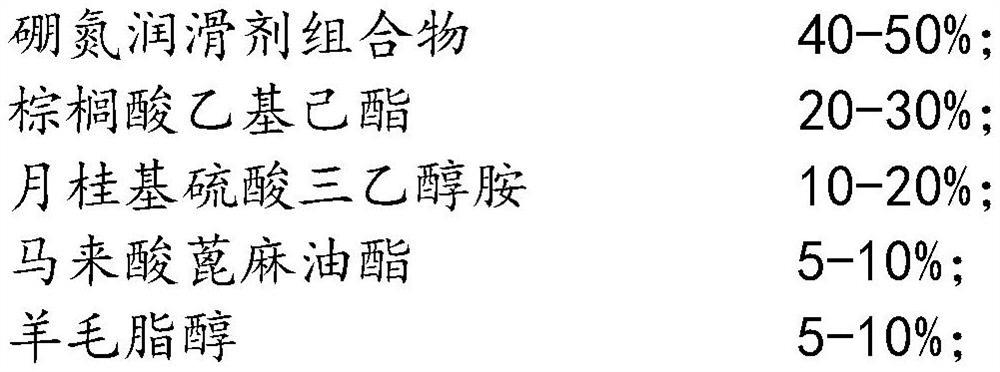

[0044] Weigh 500g of boron nitrogen lubricant composition, 200g of ethylhexyl palmitate, 100g of triethanolamine lauryl sulfate, 100g of castor oil maleate, and 100g of lanolin alcohol, mix and stir at 40°C until transparent or translucent It is a micro lubricant.

[0045] The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mo...

Embodiment 3

[0047] Step 1: Weigh 847.38 g (1.5 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them into a stirrer, stir and heat to 110° C., and fully react for 1.5 hours.

[0048] Step 2: Weigh 24.73g (0.4mol) of boric acid and add it to the stirrer of Step 1, keep it at 110°C for 3.5 hours, add 8g of hydroxyethylethanolamine and continue to stir for about 1 hour to filter, which is the boron nitrogen type lubricating oil composition.

[0049] Step 3: Weigh 500 g of polyethylene glycol (PEG1000) and add it to Step 2, and keep it at 110° C. for 2.5 hours to react to obtain a boron-nitrogen lubricant composition.

[0050] Weigh 400g of boron nitrogen lubricant composition, 300g of ethylhexyl palmitate, 200g of triethanolamine lauryl sulfate, 50g of castor oil maleate, and 50g of lanolin alcohol, mix and stir at 60°C until transparent or translucent It is a micro lubricant.

[0051] The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mol) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com