Normal temperature two-component liquid crack pouring sealant for pavements and preparation method thereof

A two-component, joint filling technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of poor aging resistance and wear resistance, difficult to meet the requirements of road joint filling, emulsified asphalt Problems such as poor bonding properties, to achieve the effect of high elongation, material saving, and enhanced bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing two-component liquid joint glue for normal temperature roads, comprising the following steps:

[0042]a. Preparation of component A:

[0043] ①. Weigh polyether polyol, chlorinated paraffin and dioctyl phthalate according to the ratio and add them to the reaction kettle, start stirring and heat up to 120°C, keep stirring and keep warm at 120°C, close the reaction kettle, and turn on the vacuum pump Vacuum to -0.02MPa for 3 hours;

[0044] ②. Stop vacuuming, stir and cool down to 85°C, add diphenylmethane diisocyanate (MDI), and react for 3 hours;

[0045] ③. After the reaction is completed, turn on the vacuum pump and continue to evacuate to -0.02MPa, keep it for 1 hour, release the closed system of the reactor and discharge; obtain A component;

[0046] b. Preparation of component B:

[0047] ④. Add polyether polyol, chlorinated paraffin, moca, coupling agent and light calcium powder into the reaction kettle, stir and heat to 120°C; then conti...

Embodiment 1

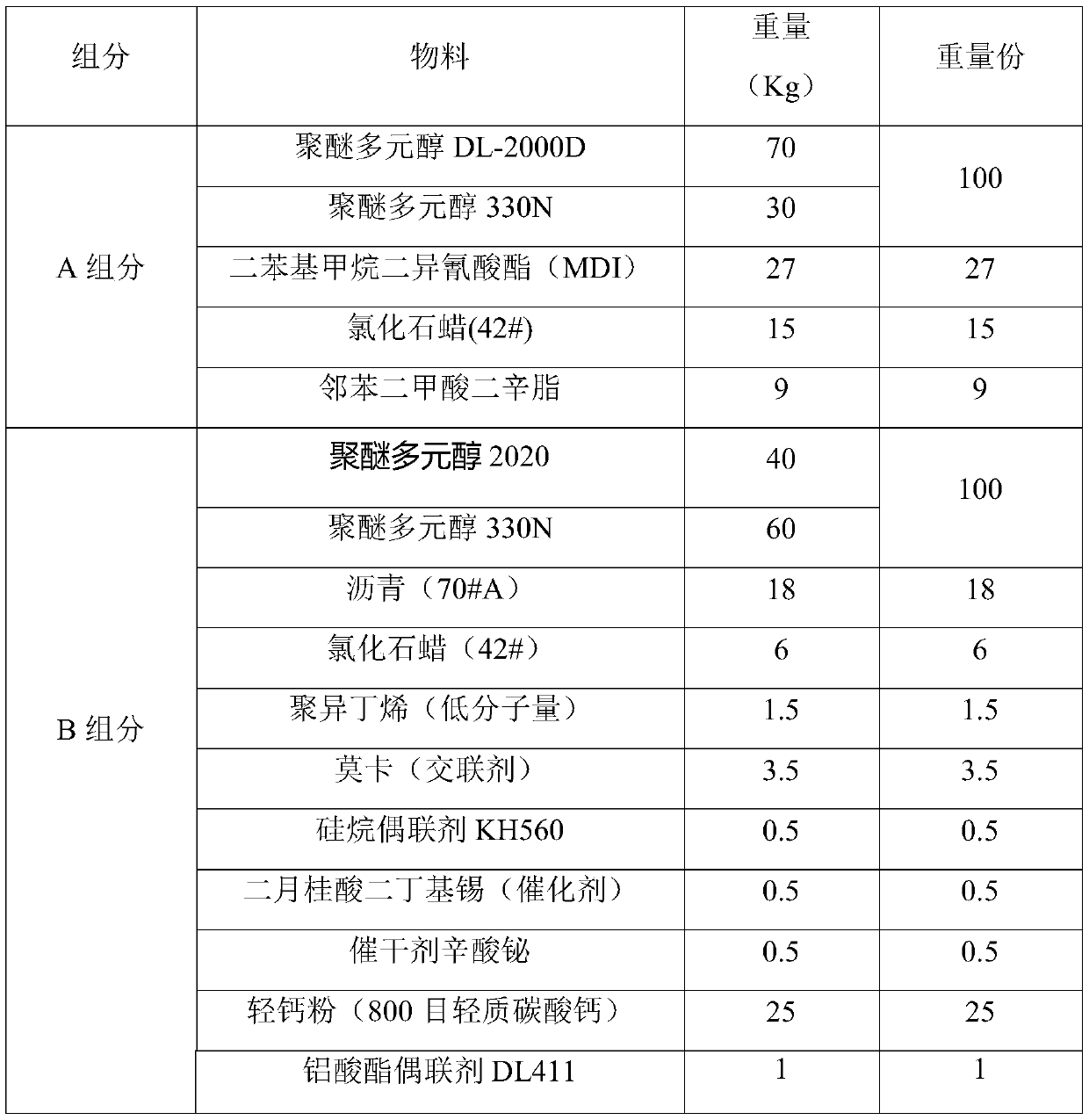

[0052] Embodiment 1 proportioning

[0053]

[0054] Preparation:

[0055] a. Preparation of component A:

[0056] ①. Weigh polyether polyol DL-2000D 80Kg, polyether polyol 330N 20Kg, chlorinated paraffin (42#) 20Kg, and dioctyl phthalate 12.5Kg according to the proportion, add them to the reaction kettle, and start stirring Heat and keep the temperature at 120°C, close the reaction kettle, turn on the vacuum pump to evacuate to -0.02MPa for 3 hours;

[0057] ②. After vacuuming is completed, turn on the water circulation to stir and cool down and keep it at 85°C, add 15Kg of diphenylmethane diisocyanate (MDI) through negative pressure, and react for 3 hours;

[0058] ③. After the reaction is completed, continue to evacuate to -0.02MPa, keep it for 1 hour, cool down to 60°C, release the closed system of the reactor and discharge; obtain A component;

[0059] b. Preparation of component B:

[0060] ④. Add polyether polyol 2020 30Kg, polyether polyol 330N70Kg, chlorinated p...

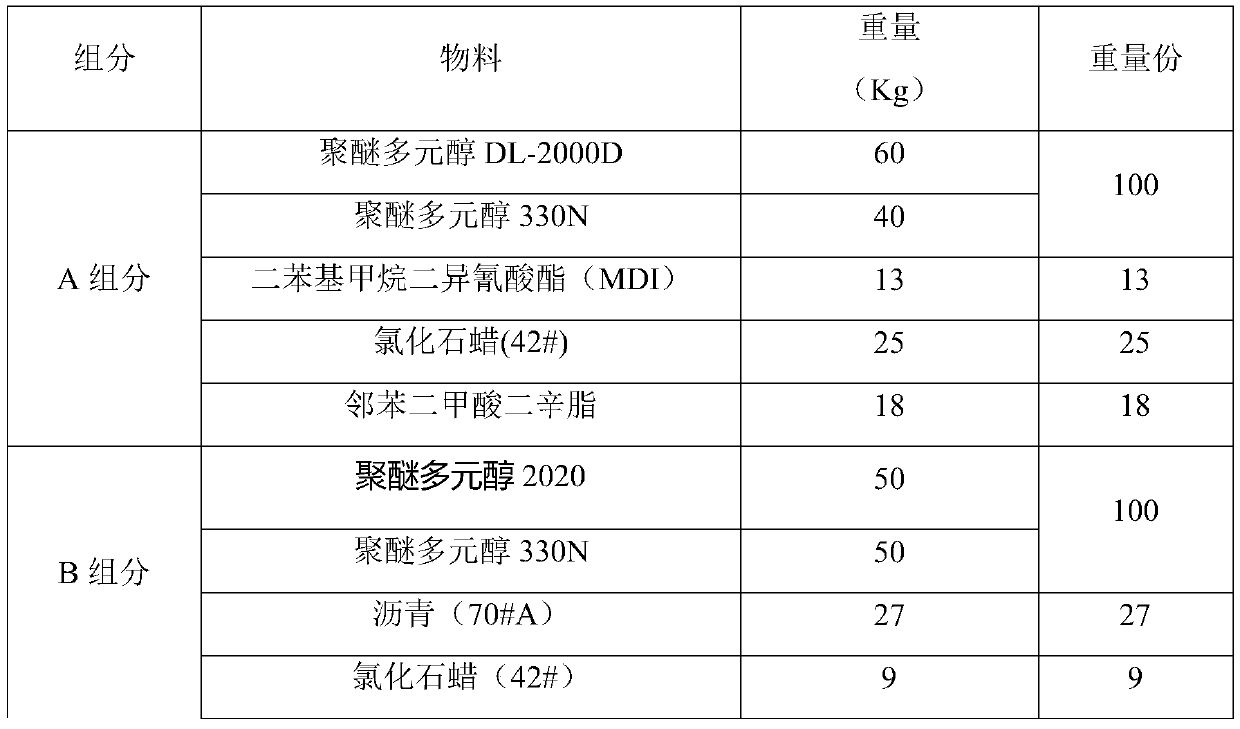

Embodiment 2

[0065] Proportion:

[0066]

[0067] Preparation:

[0068] a. Preparation of component A:

[0069] ①.Weigh 70Kg of polyether polyol DL-2000D, 30Kg of polyether polyol 330N, 15Kg of chlorinated paraffin (42#), and 9Kg of dioctyl phthalate according to the proportion, add them to the reaction kettle, stir and heat Raise the temperature to 120°C, close the reaction kettle, turn on the vacuum pump to evacuate to -0.02MPa for 3 hours, put the barreled diphenylmethane diisocyanate (MDI) into a 70°C water bath to keep warm for later use.

[0070] ②. Vacuuming is completed, turn on the water circulation and cool down to 85°C, add 27Kg of diphenylmethane diisocyanate (MDI) through negative pressure, and close the reactor for 3 hours;

[0071] ③. After the reaction is completed, continue to evacuate to -0.02MPa, keep it for 1 hour, cool down to 60°C, release the closed system of the reactor and discharge; obtain A component;

[0072] b. Preparation of component B:

[0073] ④. Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com