Waterborne acrylic acid and asphalt anti-corrosive paint and preparing technology thereof

A technology of acrylic asphalt and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of easy aging of coating films and poor application effects, and achieve good application effects, not easy to aging, and good compounding and synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

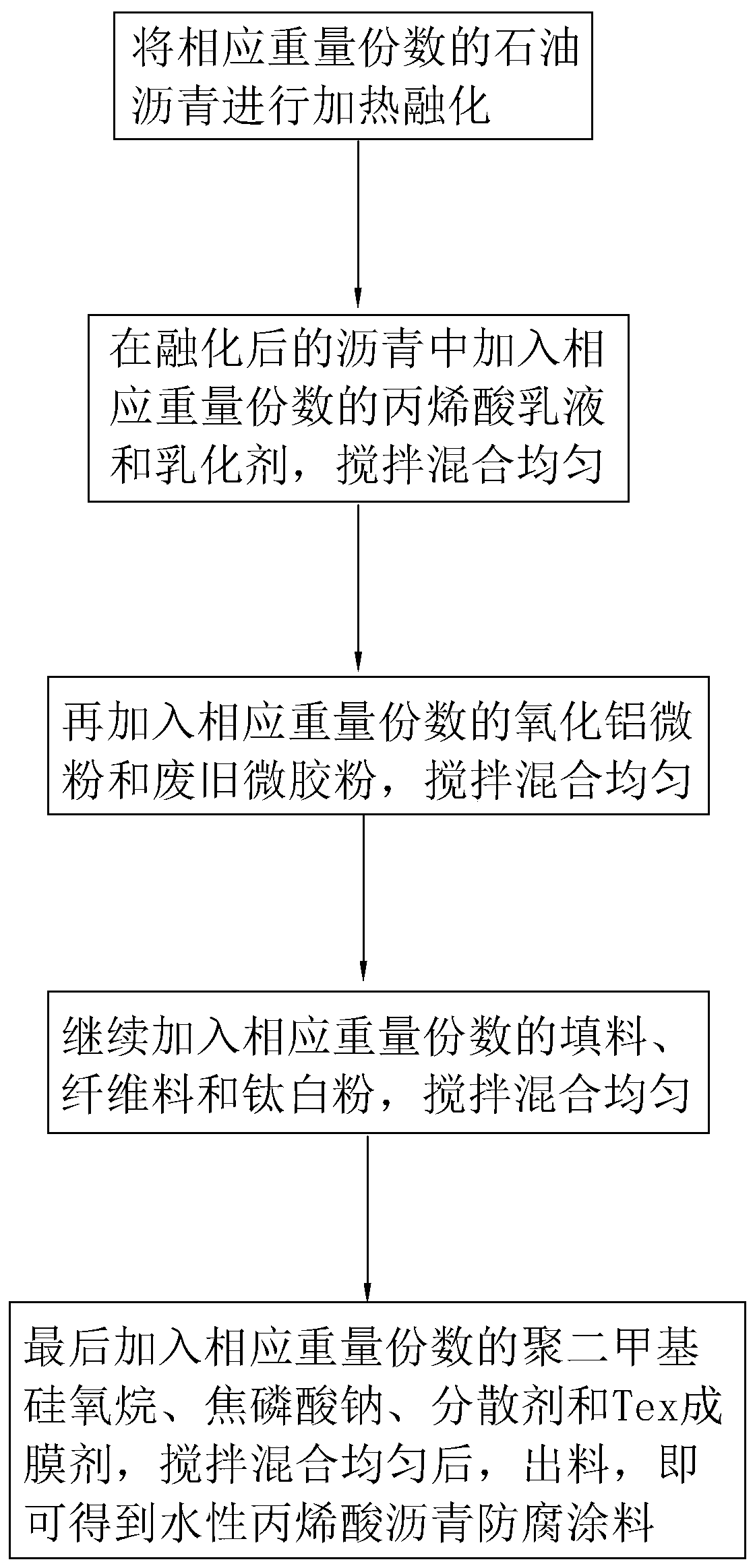

[0049] Embodiment 1: A kind of waterborne acrylic acid bitumen anticorrosion coating, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0050] Step 1, heating the petroleum asphalt in corresponding parts by weight, raising the temperature to 150° C., and heating and melting;

[0051] Step 2, add corresponding parts by weight of acrylic acid emulsion and fatty alcohol polyoxyethylene ether into the melted asphalt, stir and mix evenly, the stirring speed is 1200rpm, and the time is 20min;

[0052] Step 3, adding alumina micropowder and waste micronized rubber powder in corresponding parts by weight, stirring and mixing evenly, the stirring speed is 1500rpm, and the time is 20min;

[0053] Step 4, continue to add bentonite, basalt fiber and titanium dioxide in corresponding parts by weight, stir and mix evenly, the stirring speed is 2000rpm, and the time is 15min;

[0054] Step 5, finally add polydimethy...

Embodiment 2-8

[0056] Example 2-8: A waterborne acrylic asphalt anticorrosion coating, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0057] Each component and parts by weight thereof in table 1 embodiment 1-8

[0058]

[0059]

Embodiment 9

[0060] Embodiment 9: A kind of water-based acrylic asphalt anticorrosion coating, the difference from Example 1 is that step 4 is specifically set to continue to add the corresponding parts by weight of 1.6 parts of glass beads, 1.2 parts of basalt fiber and 2 parts titanium dioxide, stir and mix evenly, the stirring speed is 2000rpm, and the time is 15min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com