Modified PP and preparation method thereof

A modified and thermoplastic polyester technology, applied in the field of modified PP and its preparation, and the field of twin-screw extruders for the preparation of modified PP, can solve the problems of poor stiffness and impact performance, large shrinkage, easy cracking, etc. The effect of improving stiffness and impact toughness, reducing molding shrinkage, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

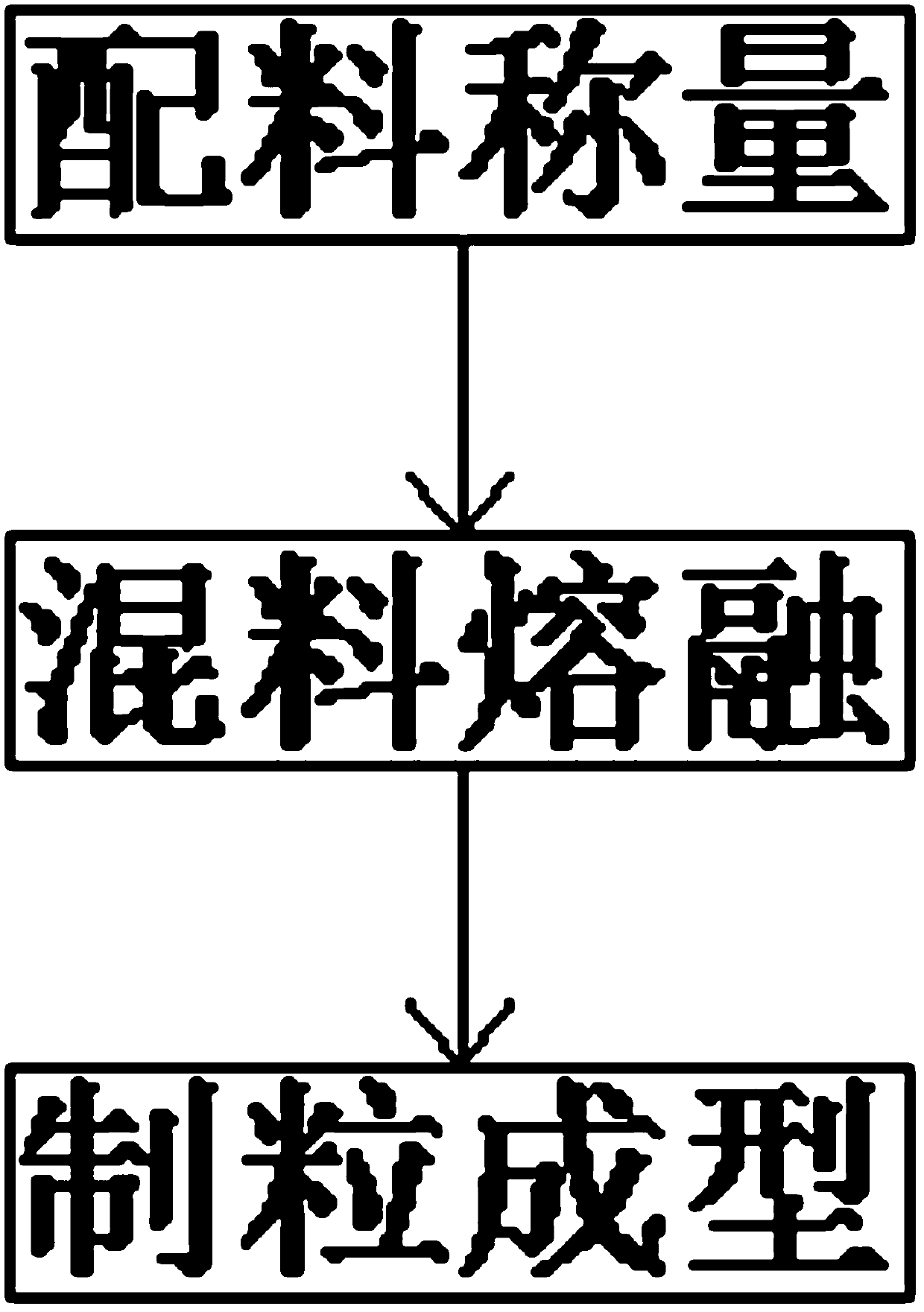

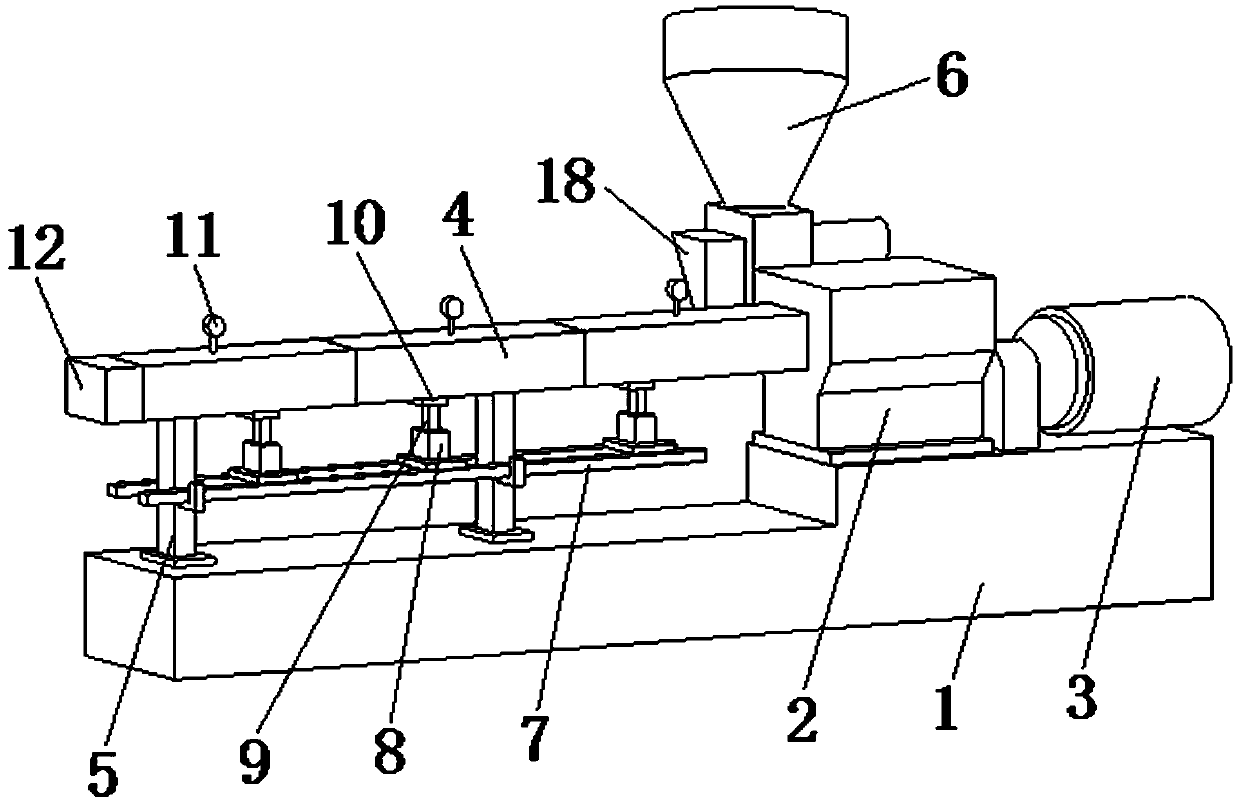

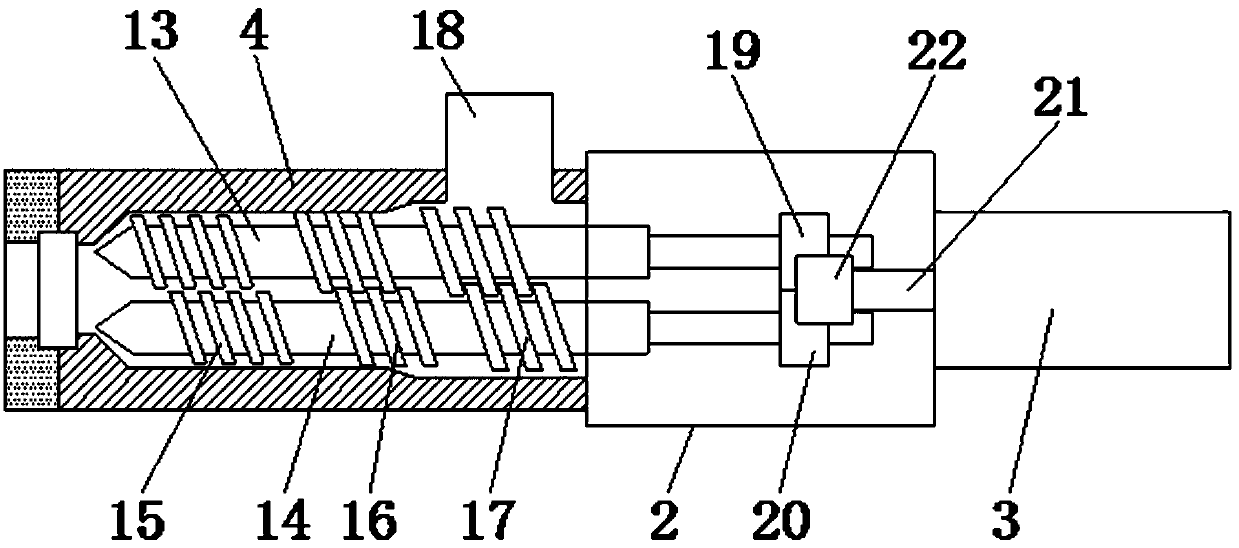

[0027] Such as figure 1 As shown, a modified PP is prepared from the following raw materials in parts by weight: 28 parts of PP resin, 30 parts of EPDM, 15 parts of talcum powder, 16 parts of polycarbonate, polyamide 14 parts, 12 parts of modified polyphenylene ether, 16 parts of thermoplastic polyester, 1 part of stabilizer, 4 parts of compatibilizer and 3 parts of antioxidant, and the stabilizer includes one of sodium silicate, urea and potassium chlorate or Various, the compatibilizer is PP-G-MAH, and the antioxidant is sec-butyl-p-phenylenediamine antioxidant.

[0028] A preparation method of modified PP, the specific steps are as follows:

[0029] (1) Ingredients weighing: Weigh the following raw materials according to parts by weight: PP resin, EPDM, talcum powder, polycarbonate, polyamide, modified polyphenylene ether, thermoplastic polyester, stabilizer agents, compatibilizers and antioxidants;

[0030] (2) Blending and melting: Add the raw materials weighed in step...

Embodiment 2

[0033] Such as figure 1As shown, a modified PP is prepared from the following raw materials in parts by weight: 29 parts of PP resin, 31 parts of EPDM, 20 parts of talcum powder, 17 parts of polycarbonate, polyamide 15 parts, 13 parts of modified polyphenylene ether, 17 parts of thermoplastic polyester, 2 parts of stabilizer, 5 parts of compatibilizer and 4 parts of antioxidant, the stabilizer includes one of sodium silicate, urea and potassium chlorate or multiple, the compatibilizer is PP-G-MAH, and the antioxidant is sec-butyl-p-phenylenediamine antioxidant.

[0034] A preparation method of modified PP, the specific steps are as follows:

[0035] (1) Ingredients weighing: Weigh the following raw materials according to parts by weight: PP resin, EPDM, talcum powder, polycarbonate, polyamide, modified polyphenylene ether, thermoplastic polyester, stabilizer agents, compatibilizers and antioxidants;

[0036] (2) Blending and melting: Add the raw materials weighed in step (1...

Embodiment 3

[0039] Such as figure 1 As shown, a modified PP is prepared from the following raw materials in parts by weight: 30 parts of PP resin, 32 parts of EPDM, 30 parts of talcum powder, 18 parts of polycarbonate, polyamide 16 parts, 14 parts of modified polyphenylene ether, 18 parts of thermoplastic polyester, 3 parts of stabilizer, 6 parts of compatibilizer and 5 parts of antioxidant, and the stabilizer includes one of sodium silicate, urea and potassium chlorate or multiple, the compatibilizer is PP-G-MAH, and the antioxidant is sec-butyl-p-phenylenediamine antioxidant.

[0040] A preparation method of modified PP, the specific steps are as follows:

[0041] (1) Ingredients weighing: Weigh the following raw materials according to parts by weight: PP resin, EPDM, talcum powder, polycarbonate, polyamide, modified polyphenylene ether, thermoplastic polyester, stabilizer agents, compatibilizers and antioxidants;

[0042] (2) Blending and melting: Add the raw materials weighed in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com