High performance anti-radiation metal fabric

A metal fabric and anti-radiation technology, which is applied in the direction of metal layered products, lamination, coating, etc., can solve the problems of wear damage, poor softness and smoothness, and easy exposure of metal fibers, so as to improve the wear resistance and improve The effect of using comfort and improving the effect of radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

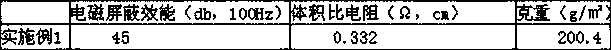

Embodiment 1

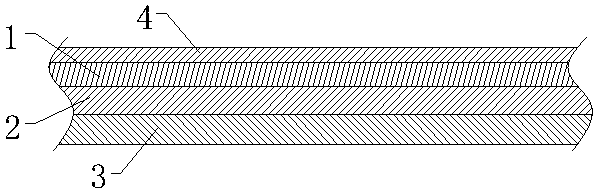

[0022] A high-performance radiation-proof metal fabric includes a wear-resistant layer 1, a radiation-proof layer 2 and a soft layer 3, the wear-resistant layer 1 is located on the upper end surface of the radiation-proof layer 2, and the radiation-proof layer 2 is located on the upper end surface of the soft layer 3.

[0023] The wear-resistant layer 1 includes 37 parts by weight of polyester fiber and 63 parts by weight of nylon fiber, and the anti-radiation layer includes 40 parts by weight of aluminum alloy fiber, 48 parts by weight of silver alloy fiber, 7 parts by weight of copper powder and 5 parts by weight of Titanium powder, soft layer comprises the bamboo fiber of 44 weight parts and the real silk fiber of 56 weight parts, and comprises following preparation steps:

[0024] Step 1, put the polyester fiber, nylon fiber, bamboo fiber and real silk fiber into the stirring kettle, then pour the antibacterial softener solution into the stirring kettle, and stir for 45min ...

Embodiment 2

[0032] A high-performance radiation-proof metal fabric includes a wear-resistant layer 1, a radiation-proof layer 2 and a soft layer 3, the wear-resistant layer 1 is located on the upper end surface of the radiation-proof layer 2, and the radiation-proof layer 2 is located on the upper end surface of the soft layer 3.

[0033] The wear-resistant layer 1 includes 55 parts by weight of polyester fiber and 45 parts by weight of nylon fiber, and the anti-radiation layer includes 50 parts by weight of aluminum alloy fiber, 42 parts by weight of silver alloy fiber, 5 parts by weight of copper powder and 3 parts by weight of Titanium powder, soft layer comprises the bamboo fiber of 67 weight parts and the real silk fiber of 33 weight parts, and comprises following preparation steps:

[0034] Step 1, put the polyester fiber, nylon fiber, bamboo fiber and real silk fiber into the stirring kettle, then pour the antibacterial softener solution into the stirring kettle, and stir for 45min ...

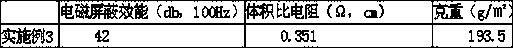

Embodiment 3

[0042] A high-performance radiation-proof metal fabric, comprising a wear-resistant layer 1, a radiation-proof layer 2 and a soft layer 3, the wear-resistant layer 1 is located on the upper end surface of the radiation-proof layer 2, and the radiation-proof layer 2 is located on the upper end surface of the soft layer 3.

[0043] The wear-resistant layer includes 45 parts by weight of polyester fiber and 55 parts by weight of nylon fiber, and the anti-radiation layer includes 44 parts by weight of aluminum alloy fiber, 46 parts by weight of silver alloy fiber, 5 parts by weight of copper powder and 5 parts by weight of titanium Powder, soft layer comprises the bamboo fiber of 50 weight parts and the real silk fiber of 50 weight parts, and comprises following preparation steps:

[0044]Step 1, put the polyester fiber, nylon fiber, bamboo fiber and real silk fiber into the stirring kettle, then pour the antibacterial softener solution into the stirring kettle, and stir for 45min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com