Preparation method and solar nitrogen fixation application of indium sulfide photocatalyst with sulfur vacancies

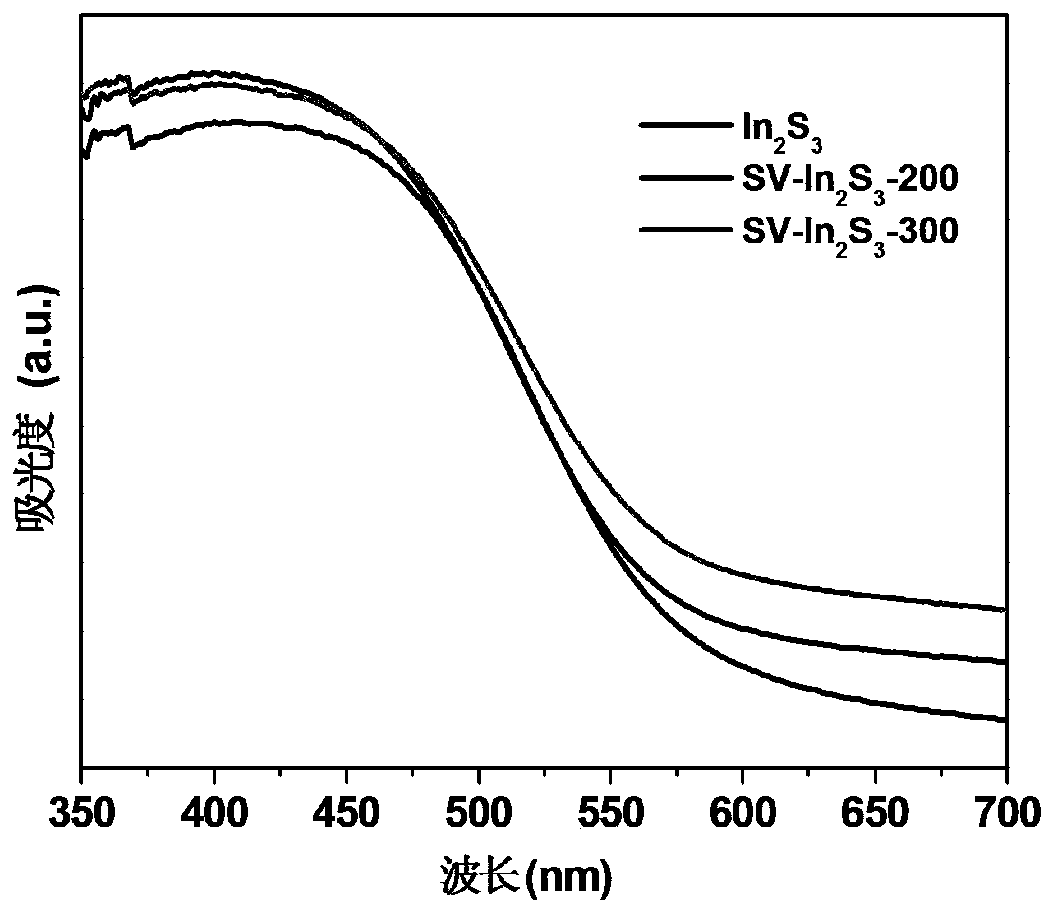

A photocatalyst and indium sulfide technology, applied in the field of photocatalytic materials, can solve the problems of low utilization rate of visible light, fast recombination of photogenerated electron holes, etc., and achieve the effects of reducing environmental pollution, high quantum efficiency and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add 0.408g of indium nitrate hydrate and 0.2g of terephthalic acid into 12mL of N,N-dimethylformamide (DMF) solution, stir thoroughly for 30min until the solution is clear, then put it into a 1-2MPa autoclave, and heat it at 100℃ Constant temperature hydrothermal reaction 48h. The product was cooled to room temperature for centrifugation and washed 6 times with N,N-dimethylformamide (DMF) and ethanol solution respectively. After vacuum drying at 60°C, the powder was collected to obtain MIL-68(In). Add 0.01g MIL-68(In) and 0.6g thiourea to 80mL ethanol solution, stir thoroughly for 30min until the solution becomes clear, then put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 180°C for 3h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the powder to obtain In 2 S 3 . will get In 2 S 3 The powder is calcined under a nitrogen ...

Embodiment 2

[0062] Add 0.408g of indium nitrate hydrate and 0.2g of terephthalic acid into 12mL of N,N-dimethylformamide (DMF) solution, stir thoroughly for 30min until the solution is clear, then put it into a 1-2MPa autoclave, and heat it at 100℃ Constant temperature hydrothermal reaction 48h. The product was cooled to room temperature for centrifugation and washed 6 times with N,N-dimethylformamide (DMF) and ethanol solution respectively. After vacuum drying at 60°C, the powder was collected to obtain MIL-68(In). Add 0.01g MIL-68(In) and 0.6g thiourea to 80mL ethanol solution, stir thoroughly for 30min until the solution becomes clear, then put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 180°C for 3h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the powder to obtain In 2 S 3 . will get In 2 S 3 The powder is calcined under a nitrogen ...

Embodiment 3

[0064] Add 0.408g of indium nitrate hydrate and 0.2g of terephthalic acid into 12mL of N,N-dimethylformamide (DMF) solution, stir thoroughly for 30min until the solution is clear, then put it into a 1-2MPa autoclave, and heat it at 100℃ Constant temperature hydrothermal reaction 48h. The product was cooled to room temperature for centrifugation and washed 6 times with N,N-dimethylformamide (DMF) and ethanol solution respectively. After vacuum drying at 60°C, the powder was collected to obtain MIL-68(In). Add 0.01g MIL-68(In) and 0.6g thiourea to 80mL ethanol solution, stir thoroughly for 30min until the solution becomes clear, then put it into a 1-2MPa autoclave, and conduct a constant temperature hydrothermal reaction at 180°C for 3h. The product was cooled to room temperature, centrifuged and washed 6 times with water and ethanol solution respectively, and dried at 60°C to collect the powder to obtain the final product In 2 S 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com