A kind of method for upgrading lignin heavy oil to prepare bio-oxygenated fuel

A technology of oxygenated fuel and heavy oil, which is applied in the field of modification and upgrading of lignin bio-oil, upgrading of low-value lignin heavy oil to prepare high-grade biological oxygenated fuel, and can solve the problem of easy coking and low efficiency of the catalyst and other problems, to achieve high energy utilization rate, suppress coking in the process, and achieve the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

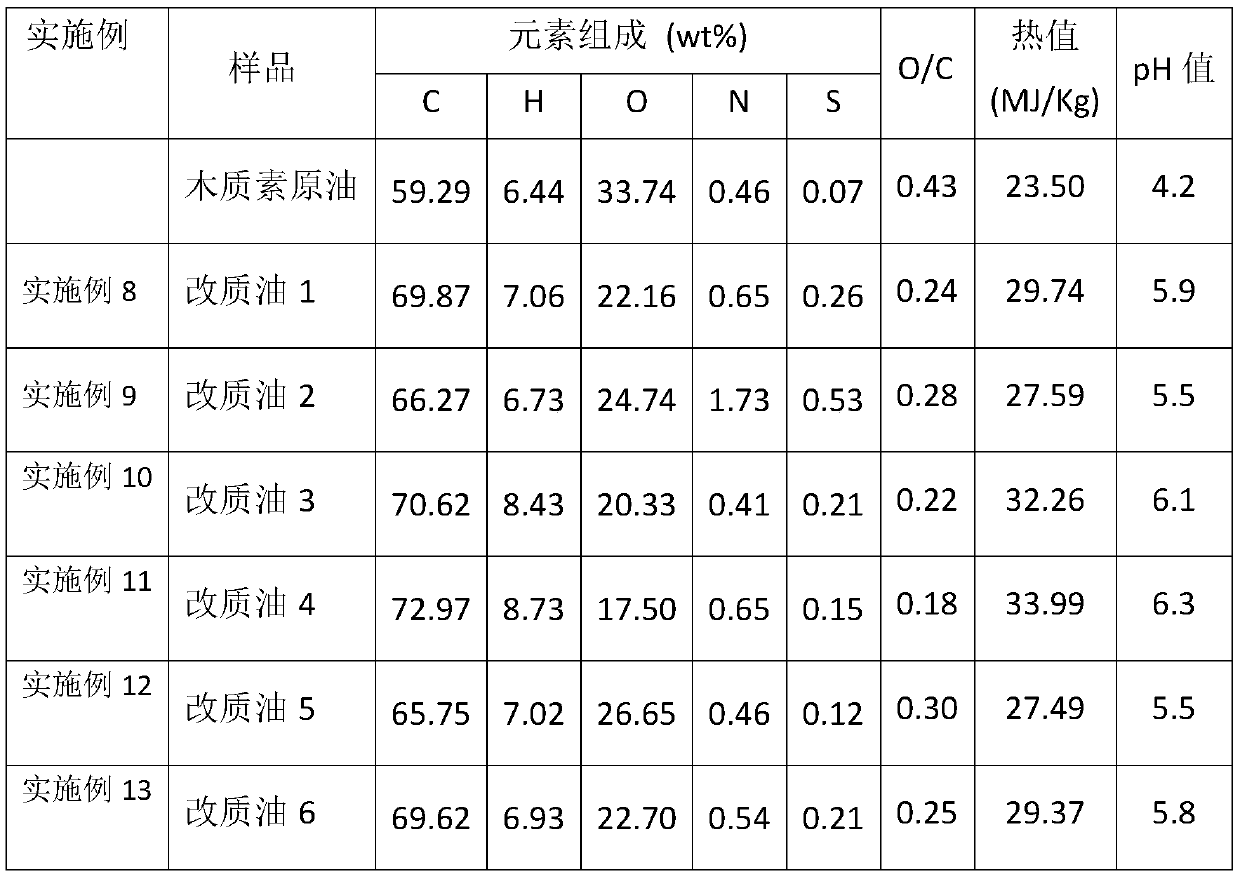

Examples

Embodiment 1

[0032] Example 1: Ni 5 / Preparation of MgO-550 catalyst

[0033] Supported catalyst Ni 5 / MgO-550 is prepared by a two-step process:

[0034] (1) Preparation of MgO carrier: 92 grams of MgCl 2 ·6H 2O was fully dissolved in 100 mL of deionized water, and then ammonia water was added dropwise to the above solution under vigorous stirring until no new precipitates occurred. The obtained white precipitate was separated by filtration and washed repeatedly with deionized water at 50 °C until the washing liquid was washed with AgNO 3 The solution does not detect Cl - . The obtained white solid was dried in an oven at 120° C., and then transferred to a muffle furnace for calcination at 850° C. for 4 hours to obtain the MgO catalyst carrier.

[0035] (2) 7.75 grams of Ni(NO 3 ) 2 Dissolved in 50mL deionized water, and then to the resulting Ni(NO 3 ) 2 50 g of MgO carrier was added to the solution, and the resulting green paste was fully dried at 120°C and then transferred t...

Embodiment 2

[0036] Example 2: Ni 20 / MgO-850 catalyst preparation

[0037] Supported catalyst Ni 20 / MgO-850 is also prepared by a two-step process

[0038] (1) Preparation of MgO carrier: The preparation method of MgO carrier is the same as the process and Example 1.

[0039] (2) 62.03 grams of Ni(NO 3 ) 2 Dissolved in 200mL deionized water, and then to the resulting Ni(NO 3 ) 2 The solution was added with 100 g of MgO carrier, and the resulting green paste was fully dried at 120°C and then transferred to a muffle furnace, calcined at 850°C for 4 hours, and then heated by 5% H 2 and 95%N 2 In the reducing gas atmosphere formed, the reduction is carried out at 650°C for 4 hours, and the gray-black solid obtained at last is Ni 20 / MgO-850 catalyst.

Embodiment 3

[0040] Embodiment 3: Catalyst Ni 15 / MgO-SiO 2 Preparation of -650

[0041] Supported catalyst Ni 15 / MgO-SiO 2 -650 was prepared by a two-step process:

[0042] (1) Preparation of catalyst carrier: 81.2 grams of MgCl 2 ·6H 2 O and 48.8 g Na 2 SiO 3 Fully dissolve in 100mL deionized water, and then add ammonia water dropwise to the above solution under vigorous stirring until no new precipitate occurs. The obtained white precipitate was separated by filtration and washed repeatedly with deionized water at 50 °C until the washing liquid was washed with AgNO 3 The solution does not detect Cl - . Dry the obtained white solid in an oven at 120°C, and then transfer it to a muffle furnace for calcination at 550°C for 5 hours to obtain MgO-SiO 2 Catalyst carrier.

[0043] (2) 23.25 grams of Ni(NO 3 ) 2 Dissolved in 50mL deionized water, and then to the resulting Ni(NO 3 ) 2 Add 50 g of MgO-SiO to the solution 2 Carrier, the resulting green paste was fully dried at 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com