Method for removing hydrogen fluoride in tetrafluoroethylene production process

A production process, tetrafluoroethylene technology, applied in the direction of chemical instruments and methods, chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve the problems of excessive fluoride ion content, reduced operating rate of equipment, low quality, etc., to achieve good economy and Social benefit, reduction of hydrogen fluoride content, effect of reducing fluoride ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

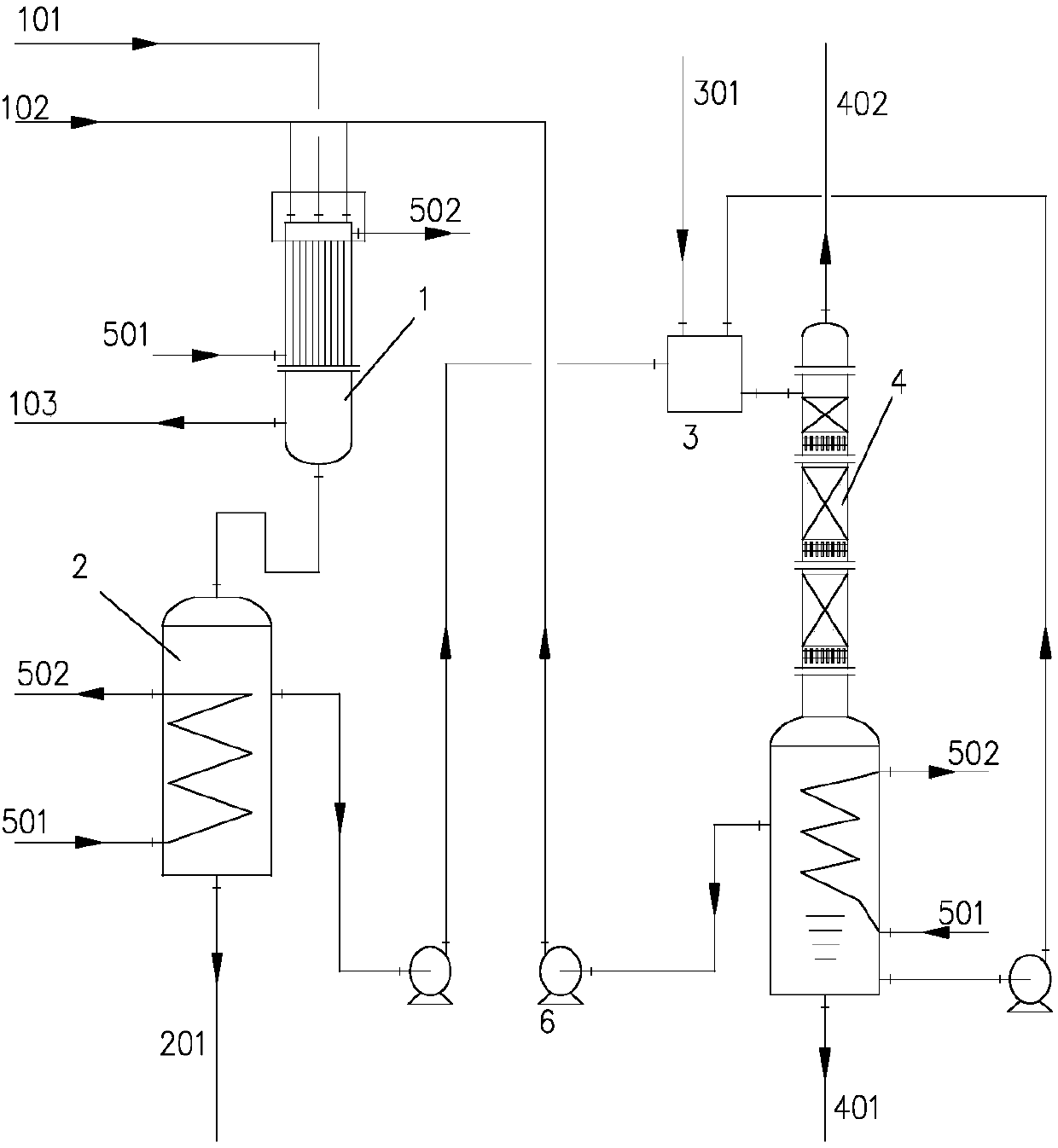

[0037] see figure 1 , the system used for removing hydrogen fluoride used in the method comprises a defluorination tower 1 clarification stratified tank 2, a mixer 3, and a regeneration tower 4;

[0038] The top of the defluorination tower is connected with a cracked gas feed pipe 101 and a defluorination agent feed pipe 102, and the gas phase material outlet 103 provided at the bottom of the defluorination tower is used to transport the defluorination cracked gas to the follow-up system; the defluorination tower The bottom is connected to the clarified stratified tank 2 through a pipeline, and the clarified stratified tank is connected to the mixer 3 through a pipeline, and the mixer 3 is connected to the regeneration tower 4; the lower part of the regeneration tower is passed through a lye circulation pipeline It is connected to the mixer; the bottom of the regeneration tower is provided with a sodium fluoride waste liquid discharge port 401, and an emptying valve 402 is pro...

Embodiment 2

[0047] Adopt and the system of embodiment 1 system, the operation of removing hydrogen fluoride comprises steps:

[0048] The first step is defluorination by extraction reaction: the cracked gas containing tetrafluoroethylene, water vapor and hydrogen fluoride flows into the defluorinator in parallel with the defluorinating agent from the regeneration tower at 135-150 ° C, and the cracked gas after defluorination goes to In the follow-up system, the mixed liquid after defluorination enters the clarification and stratification tank. The defluorinating agent is tetrabutoxysilane, the density is 0.899g / m 3 The amount of additional defluorination agent relative to the cracked gas material is 0.3kg / t; the defluorination pressure is controlled to 0.05Mpa, the defluorination temperature is 45°C; the liquid-gas mass ratio is 7:1; the residence time of the material in the defluorination device is 2~ 3min.

[0049] The second step is clarification and stratification: the mixed liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com