Method for carrying out biochemical treatment on landfill leachate by using circulating upflow sludge bed

A landfill leachate, circulating upstream technology, applied in the treatment of polluted groundwater/leachate, water/sludge/sewage treatment, anaerobic digestion treatment, etc., can solve difficult operation and management, high operating cost and poor biodegradability and other problems, to achieve the effect of simple operation and management, low operating cost and large volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

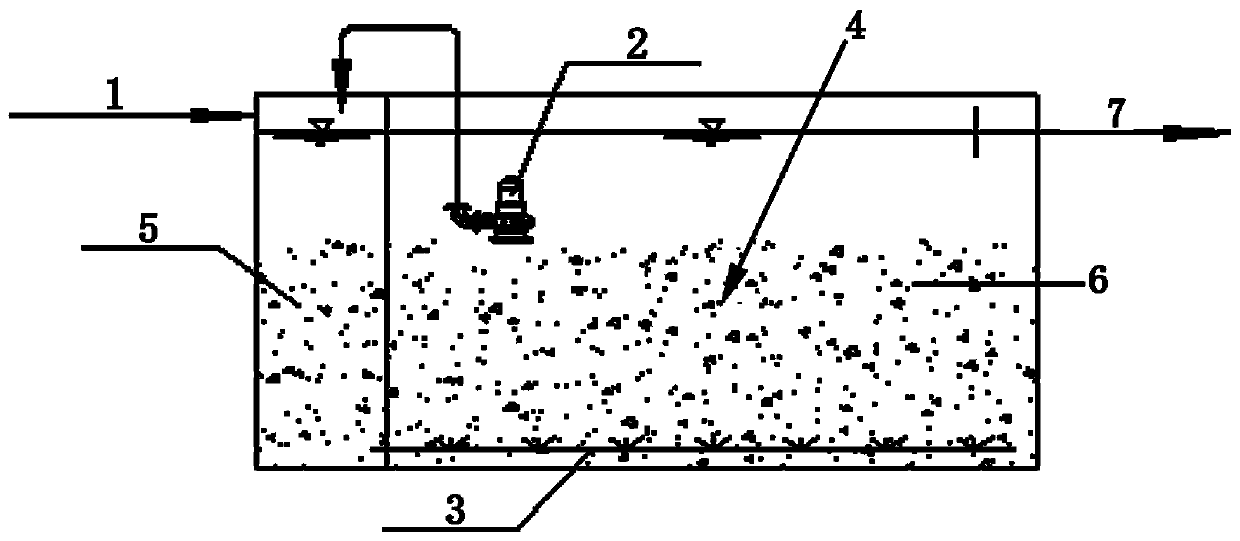

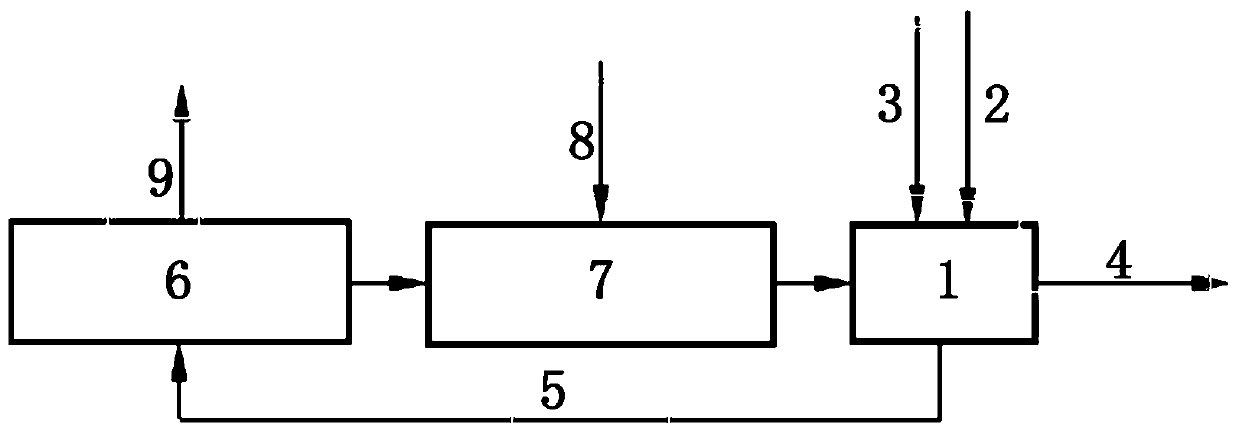

[0053] See figure 1 , figure 2 Shown: biochemical treatment method of landfill leachate in circulating upstream sludge bed, process flow of landfill leachate treatment:

[0054] Preheat the mixing pool

[0055] The preheating mixing tank uses the waste heat in the leachate discharged outward to heat the leachate and industrial starch entering the leachate treatment tank to 15-20°C and mix fully to increase the BOD of the leachate 5 The ratio of / CODcr is straight, improving the biodegradability of leachate.

[0056] The mixed solution enters the circulating upflow sludge bed anaerobic reaction tank.

[0057] Circulating upstream sludge bed anaerobic reaction tank

[0058] The mixed solution is injected upwards from the bottom by the water distributor in the anaerobic reaction tank, and then the water in the reaction tank is introduced into the reflux tank by the circulating pump, and then the reflux tank is injected from the bottom by the water distributor, and the wastew...

Embodiment 2

[0070] Add 0.08t industrial sugar and 3t water to 15t leachate.

[0071] The reaction time of anaerobic reaction is 15d, and that of facultative oxygen reaction is 10d.

[0072] The substrate is also called industrial starch, which is industrial sugar or municipal sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com