Method of making wiring board with interposer and electronic component incorporated with base board

A technology of electrical components and base boards, which is applied in the manufacture of printed circuits connected with non-printed electrical components, electrical components, printed circuits, etc., can solve problems such as limited electrical efficiency, improve electrical characteristics, and increase wiring flexibility degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

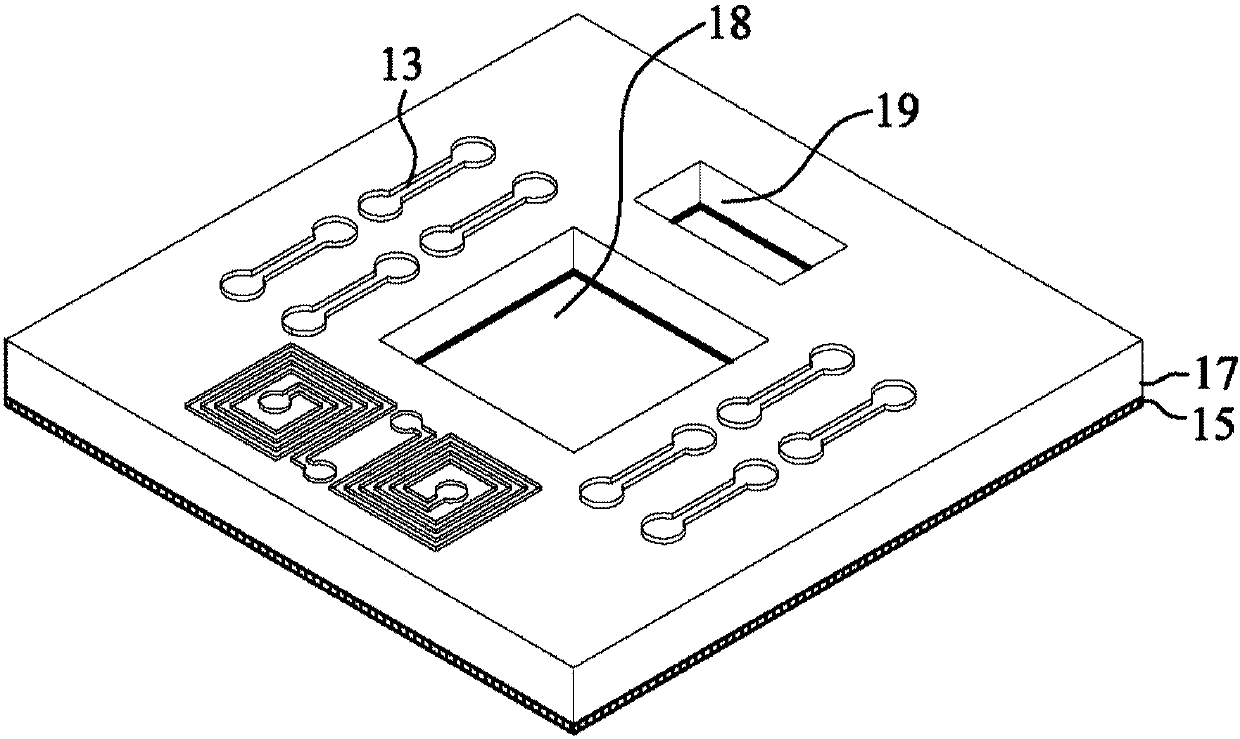

[0091] Figure 18-22 It is a diagram of the manufacturing method of the circuit board with the bottom circuit layer in the second embodiment of the present invention.

[0092] For the purpose of brief description, any descriptions in the above-mentioned embodiment 1 that can be used for the same application are incorporated here, and it is not necessary to repeat the same descriptions.

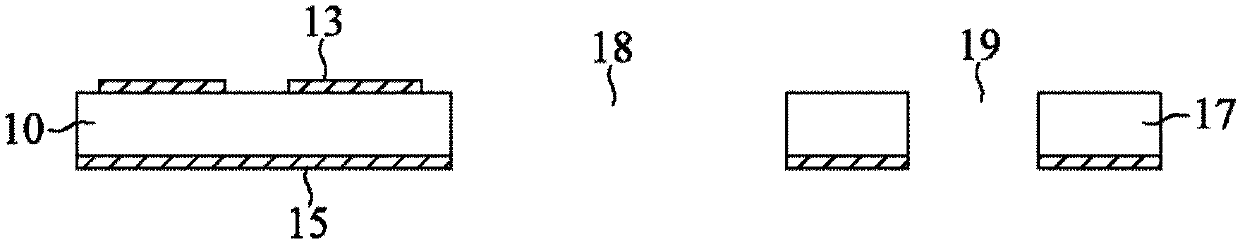

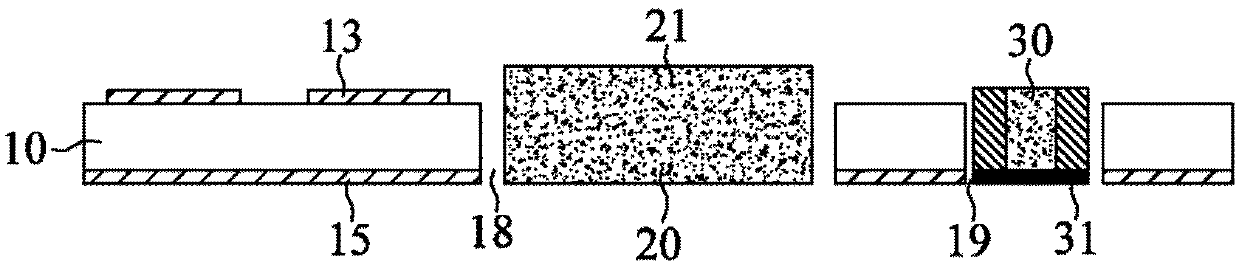

[0093] Figure 18 It is a schematic cross-sectional view of the interposer 20 and the electrical element 30 respectively disposed in the first through opening 18 and the second through opening 19 of the base board 10 . The base plate 10 is similar to figure 1 The structure shown differs in that it also includes metallized vias 14 in the core layer 17 . The metallized via 14 extends through the core layer 17 to provide an electrical connection between the top wiring layer 13 and the bottom metal film 15 .

[0094] Figure 19 It is a schematic cross-sectional view of forming the dielectric ...

Embodiment 3

[0106] Figure 30 It is a schematic cross-sectional diagram of a circuit board according to the third embodiment of the present invention, and its dielectric layer also covers the top surface of the interposer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com