Graphite negative material, preparation method thereof and cell

A graphite anode and raw material technology, applied in the direction of graphite, battery electrodes, chemical instruments and methods, etc., can solve the problems of high cost, limited development and application, etc., and achieve the effects of low cost, good charge-discharge cycle performance, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the graphite negative electrode material of one embodiment of the present invention, comprises the following steps:

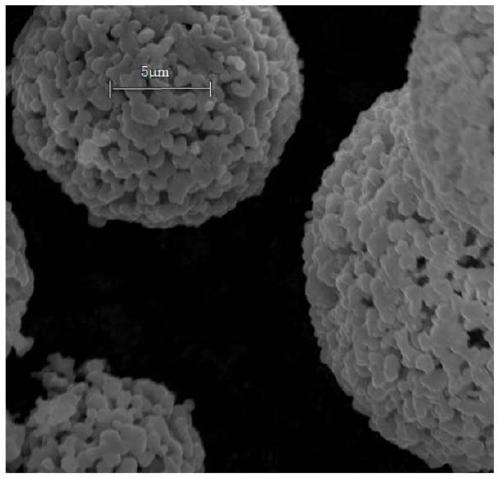

[0035] S101: Mixing the cellulose raw material, catalyst and dispersant, ball milling and drying to obtain nanocrystalline spheroidized precursor particles.

[0036] Among them, the cellulose raw material can be the rhizome, core shell, etc. of plants rich in cellulose, which is not particularly limited here, and can be pulverized by a crushing device to obtain a cellulose raw material with a desired particle size. It can also directly adopt commercially available industrial cellulose raw materials.

[0037] In the present invention, the catalyst is a co-catalyst composed of a nickel-containing compound and an electron-deficient compound. Since nickel is a transition metal element, it has a strong hydrodehydrogenation effect, and the electron-deficient compound has the effect of stabilizing carbocations. Under the synergistic e...

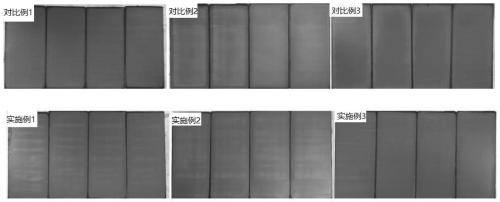

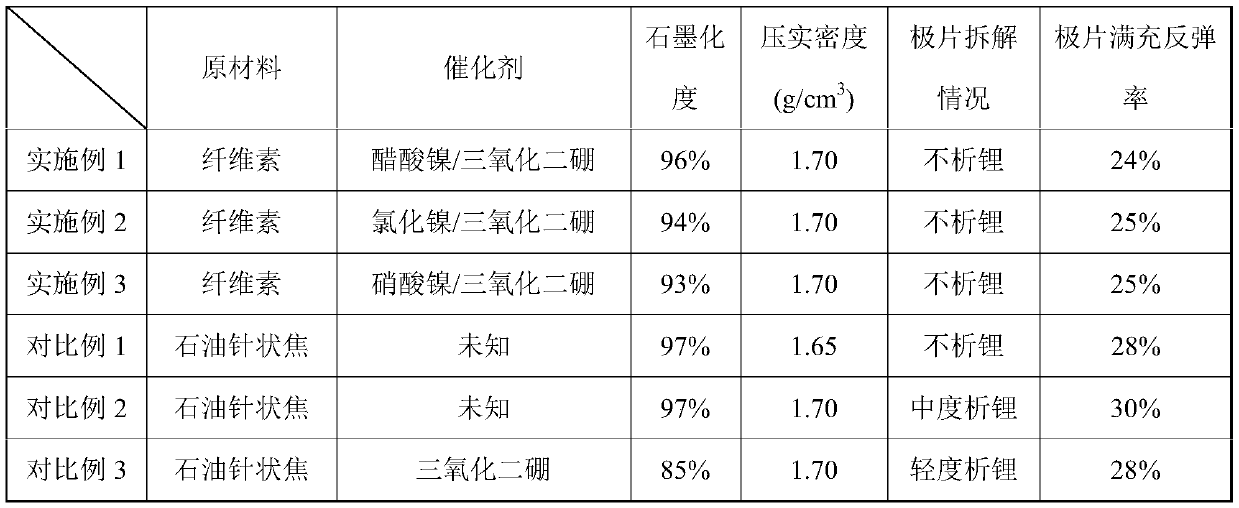

Embodiment 1

[0054] Mix cellulose raw material, dispersion medium, dispersant (content 1%), defoamer (content 0.2-0.5%), co-catalyst nickel acetate / boron trioxide (content 0.5-2%) into the planetary ball mill, The planetary ball is ground for 5-10 hours to obtain a slurry (solid content: 40%), and the slurry is sprayed and granulated to obtain nanocrystalline spheroidized precursor particles with a particle size of 5-30 μm.

[0055] The spray-dried nanocrystalline spheroidized precursor particles were placed in a muffle furnace for heat treatment, and a stepwise heating program was adopted with an upper limit temperature of 1000°C for sintering for 96 hours.

[0056] After cooling, it was transferred to a medium frequency induction graphitization furnace, and nitrogen gas was introduced to carry out high-temperature graphitization. The graphitization temperature was 2000°C and the time was 24 hours. After graphitization, cool and demagnetize and pass through a 250-mesh sieve to prepare the...

Embodiment 2

[0060] Mix cellulose raw material, dispersion medium, dispersant (content 1%), defoamer (content 0.2-0.5%), co-catalyst nickel chloride / boron trioxide (content 0.5-2%) into the planetary ball mill , planetary ball milling for 5-10 hours to obtain slurry (solid content: 40%), and the slurry is sprayed and granulated to obtain nanocrystalline spheroidized precursor particles with a particle size of 5-30 μm.

[0061] The spray-dried nanocrystalline spheroidized precursor particles were placed in a muffle furnace for heat treatment, and a stepwise heating program was adopted with an upper limit temperature of 1000°C for sintering for 96 hours.

[0062] After cooling, it was transferred to a medium frequency induction graphitization furnace, and nitrogen gas was introduced to carry out high-temperature graphitization. The graphitization temperature was 2000°C and the time was 24 hours. After graphitization, cool and demagnetize and pass through a 250-mesh sieve to prepare the graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com