Light emitting device, preparation method thereof and application

A light-emitting device and a common technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of increasing the luminous efficiency of light-emitting devices, the inability to produce green effects, and the luminous efficiency to be improved, so as to improve the appearance Effects of quantum efficiency, improved recombination efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

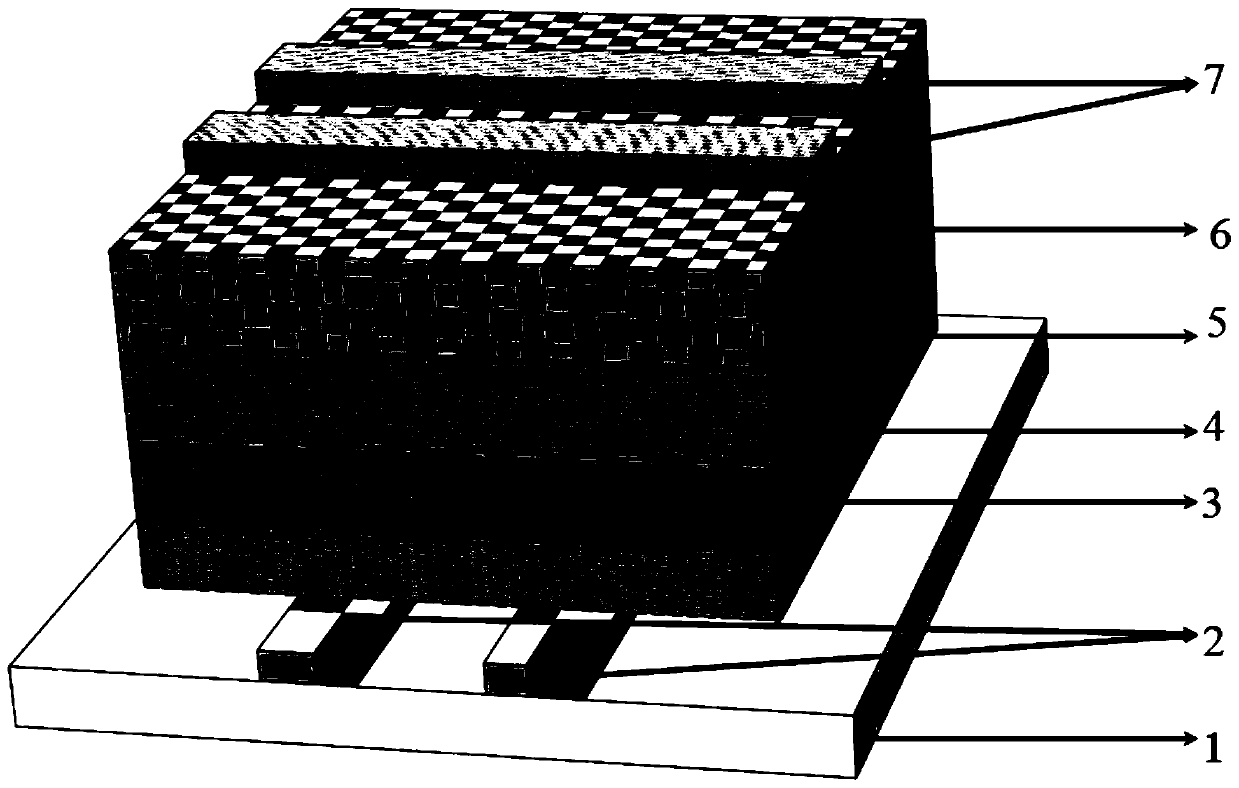

[0114] This embodiment provides a light emitting device, such as figure 1 As shown: the light-emitting device sequentially includes a base layer 1, an anode layer 2, a first hole transport layer 3, a second hole transport layer 4, a quantum rod layer 5, and an electron transport layer 6 combined together from bottom to top And cathode layer 7, wherein base layer 1 is a glass base layer; Anode layer 2 is an ITO conductive glass layer; The first hole transport layer 3 is a PEDOT:PSS hole transport layer; The second hole transport layer 4 is a PVK hole Transport layer; the quantum rod layer 5 is a CdSe / CdS quantum rod layer in the red light band, and its fluorescence emission wavelength is 630nm; the electron transport layer 6 is a ZnMgO layer; the cathode layer 7 is an aluminum electrode layer, and its thickness is 500nm.

[0115] This embodiment also provides a method for preparing a light-emitting device, and the method includes the following steps:

[0116] (1) Deposit an IT...

Embodiment 2

[0124] This embodiment provides a light-emitting device, the light-emitting device sequentially includes a base layer, an anode layer, a first hole transport layer, a second hole transport layer, a quantum rod layer, and an electron transport layer combined together from bottom to top. And the cathode layer, wherein the base layer is a glass base layer; the anode layer is an ITO conductive glass layer; the first hole transport layer is a PEDOT:PSS hole transport layer; the second hole transport layer is a PVK hole transport layer; The layer is a CdSe / CdS quantum rod layer in the red light band, and its fluorescence emission wavelength is 600nm; the electron transport layer is a ZnMgO layer; the cathode layer is an aluminum electrode layer, and its thickness is 1000nm.

[0125] This embodiment also provides a method for preparing a light-emitting device, and the method includes the following steps:

[0126] (1) Deposit an ITO conductive film on the glass base layer, obtain the ...

Embodiment 3

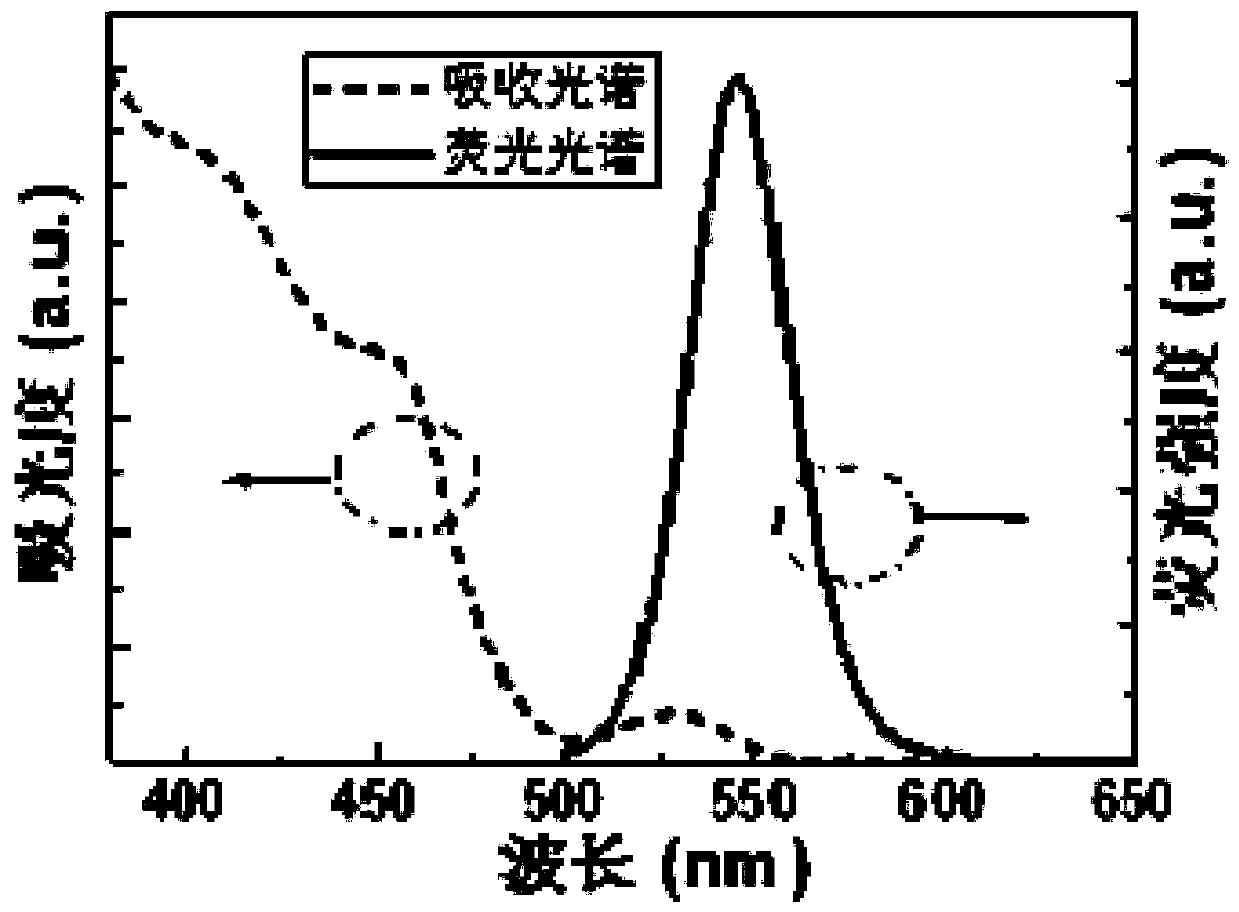

[0134]This embodiment provides a light-emitting device, the light-emitting device sequentially includes a base layer, an anode layer, a first hole transport layer, a second hole transport layer, a quantum rod layer, and an electron transport layer combined together from bottom to top. And the cathode layer, wherein the base layer is a glass base layer; the anode layer is an ITO conductive glass layer; the first hole transport layer is a PEDOT:PSS hole transport layer; the second hole transport layer is a PVK hole transport layer; The layer is a CdSe / CdS quantum rod layer in the green light band, and its fluorescence emission wavelength is 560nm; the electron transport layer is a ZnMgO layer; the cathode layer is an aluminum electrode layer, and its thickness is 100nm.

[0135] This embodiment also provides a method for preparing a light-emitting device, and the method includes the following steps:

[0136] (1) Deposit an ITO conductive film on the glass base layer, obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com