Self-powered photoelectric detection structure based on graphene-gallium oxide phase junction, device and preparation method

A photoelectric detection and gallium oxide technology, which is applied in the field of photoelectric detection, can solve the problems such as the reduction of photodetection rate, and achieve the effects of high sensitivity, easy large-scale production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

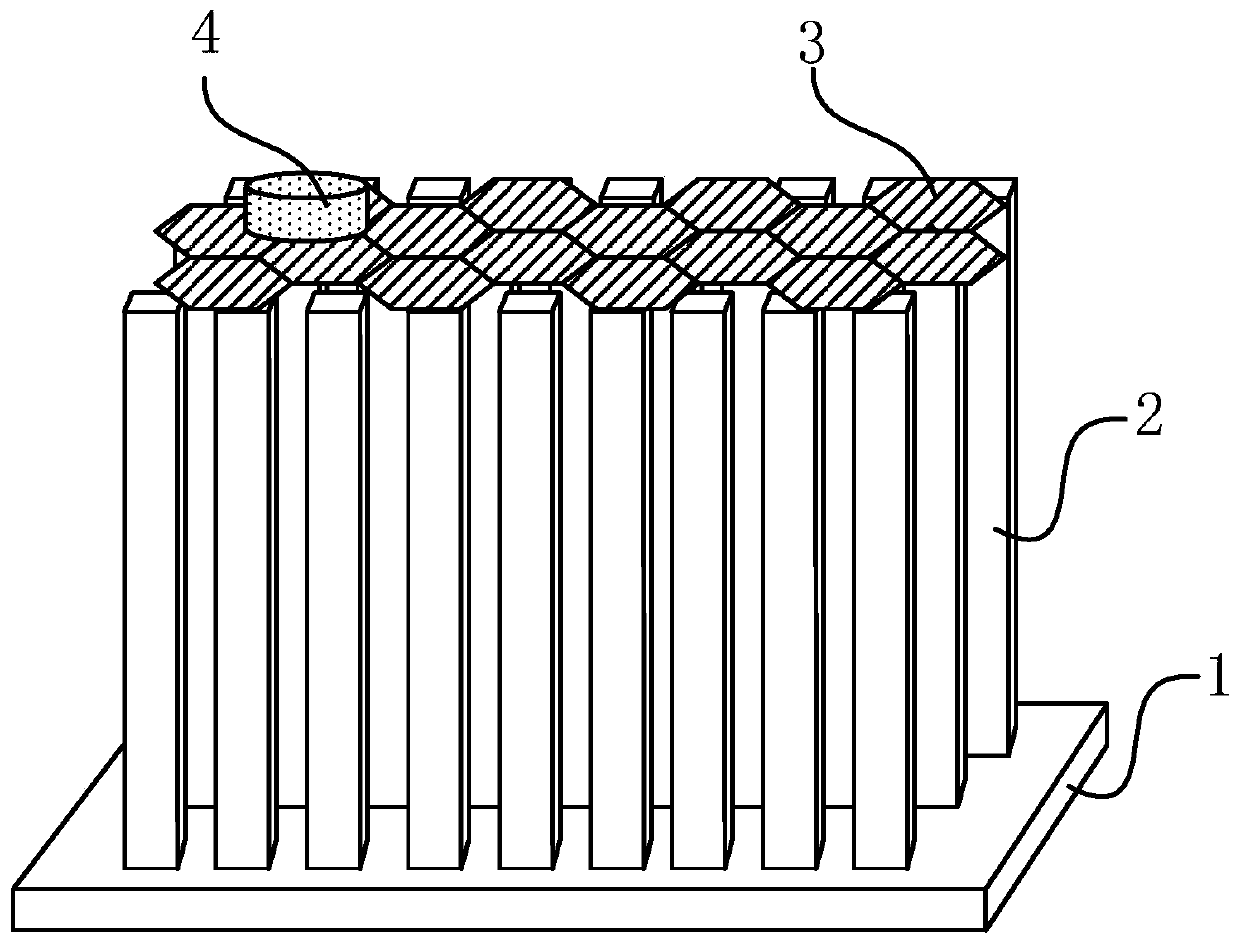

[0037] A graphene-α / β-Ga based 2 o 3 Phase-junction nanocolumn solar-blind ultraviolet detector, its preparation method is as follows:

[0038] (1) Pretreatment of the FTO conductive glass substrate: Ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 10 min, and then drying in an oven.

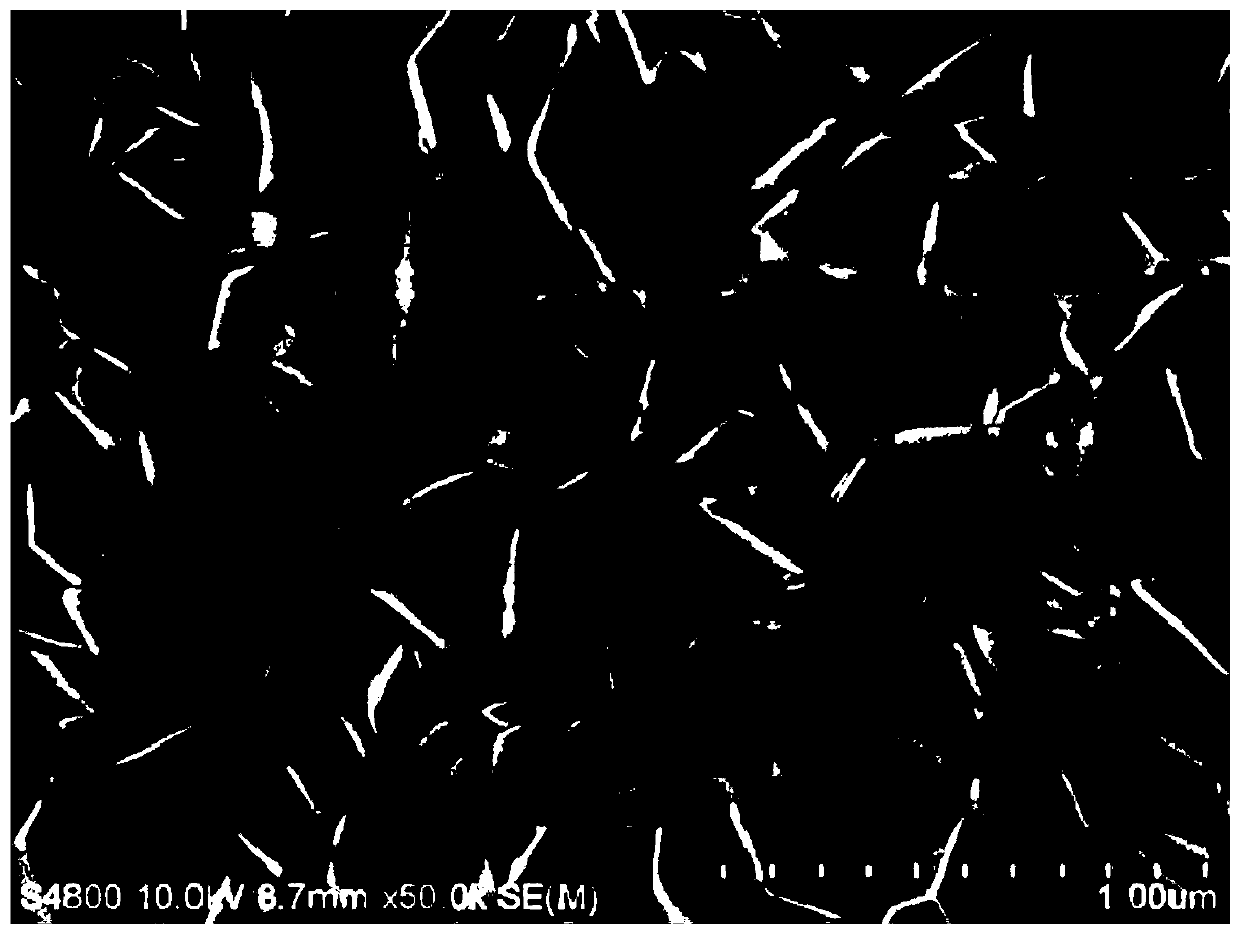

[0039] (2) Preparation of α / β-Ga by hydrothermal method and annealing method 2 o 3 Nanopillar array: lean the FTO conductive glass against the inner wall of the stainless steel autoclave, add 5-10mL of 0.5g / 30mL Ga(NO 3 ) 3 The growth solution (covering 80% of the substrate), tightening the reaction vessel, and heating in an oven at 150° C. for 6 to 12 hours, can obtain GaOOH nanocolumn arrays grown along the (110) crystal plane. After the reaction was completed, the FTO substrate was taken out, rinsed with deionized water, and dried at 50°C. Then the gallium oxyhydroxide nanocolumn array was annealed at 500 °C for 4 hours to prepare α-Ga 2 o 3 array of nanopilla...

Embodiment 2

[0045] Steps (1), (2), (3) and (4) are all the same as in Example 1. After step (4) finishes, use the obtained graphene / nano-column / FTO sample to scoop up another piece of etching and clean it completely clean graphene. PMMA / bilayer graphene / α / β-Ga 2 o 3 After the nanocolumn / FTO sample was air-dried for 8 hours, put it on a constant temperature table to dry the sample completely, and then put it into a dichloromethane solution at 40°C to remove the PMMA glue; to obtain the sample double-layer graphene / α / β-Ga 2 o 3 Nanopillars / FTO.

[0046] The resulting bilayer graphene / α / β-Ga 2 o 3 The nanocolumn / FTO structure is similar to Example 1. Based on bilayer graphene / α / β-Ga 2 o 3 A voltage is applied across the electrodes of the nanocolumn / FTO sun-blind ultraviolet detector to measure the photoelectric performance. The I-t curve is measured at a voltage of 0 volts. It is found that the current changes instantaneously when the ultraviolet light switch is controlled, indicatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com