Split-Hopkinson tension bar test piece fixture and mounting method

A separate, test piece technology, applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of high test accuracy and unlimited test piece materials, and achieve a wide range of applications , high test data accuracy and precision, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

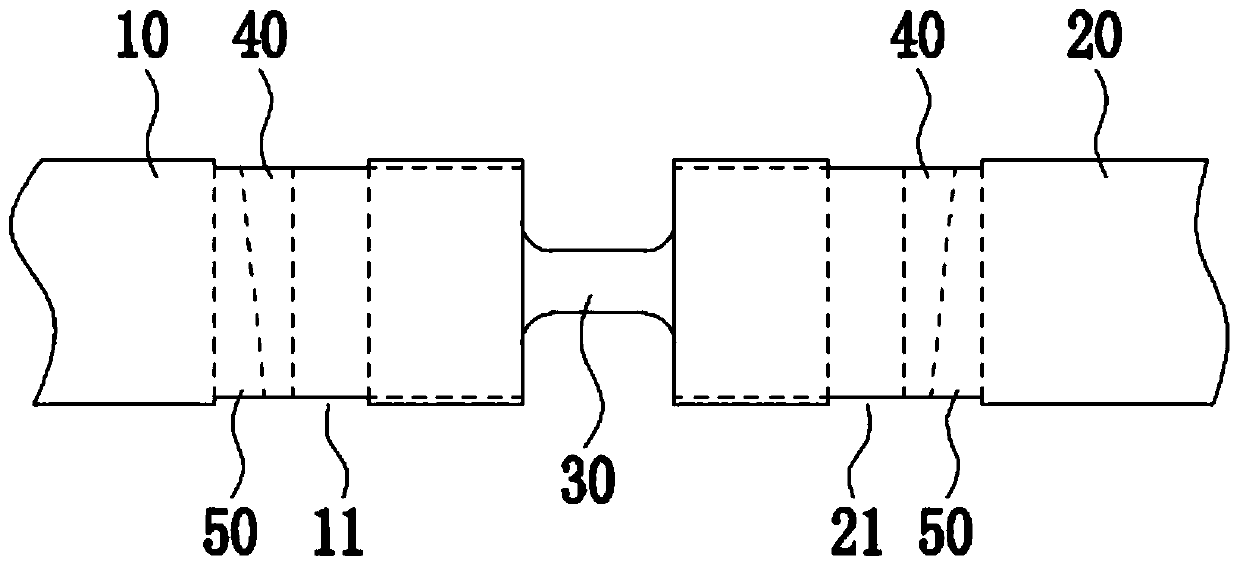

[0050] A separate Hopkinson tie rod specimen fixture, such as figure 1 , 2 As shown, it includes: an incident rod 10, one end of which is provided with a slot I11 for clamping a test piece 30; and a transmission rod 20, one end of which is provided with a slot II21 for clamping a test piece 30; Block B50, which cooperates with each other to fill in the gap between the two ends of the test piece 30 and the slot I11 and slot II21. The purpose of reserving the gap between the slot I11 and the bottom surface of the slot II21 is to facilitate the clamping of the test piece 30 .

[0051] When loading the test piece 30, firstly snap the two ends of the test piece 30 into the slots I11 and II21 respectively, and then insert the wedge block A40 and the wedge-shaped Block B50, when clamping wedge-shaped block A40 and wedge-shaped block B50, insert wedge-shaped block A40 and wedge-shaped block B50 from the notches on both sides of the card slot I11 and card slot II21 respectively, and ...

Embodiment 2

[0055] A kind of split-type Hopkinson rod test piece fixture of the present embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: figure 1 As shown, the said slot I11 and slot II21 are both "T" shaped through slots arranged radially along the rod. During the test, as image 3 As shown, the two ends of the test material are processed into a test piece 30 with a "T"-shaped connection end matched with the through groove. Since this structure is relatively simple, it is very easy to process.

Embodiment 3

[0057] A kind of split-type Hopkinson rod test piece fixture of the present embodiment, the basic structure is the same as that of embodiment 1 or 2, the differences and improvements are as follows: figure 1 As shown, the incident rod 10 and the transmission rod 20 are arranged coaxially, so that during the test, the tensile force of the incident rod 10 and the transmission rod 20 on the test piece 30 is collinear and opposite, preventing the test piece 30 from being biased due to force. Torque is generated to ensure the accuracy and precision of the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com