A-D-A type nano-corner lattice with thermal activation delayed fluorescence properties and preparation method and application thereof

A technology of A-D-A and thermal activation delay, applied in chemical instruments and methods, organic chemistry, luminescent materials, etc., can solve the problems of short working life of devices, unsatisfactory requirements, poor chemical stability, etc., and achieve electronic energy level adjustable, large Rigidity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also discloses a preparation method of A-D-A type nano cutaway lattice with thermally activated delayed fluorescence properties, the method comprises the following steps:

[0055] S1: to Ar 1 The group is borated, and the brominated fluorenone compound is prepared into a fluorenyl tertiary alcohol by using the Grignard reaction;

[0056] S2: Using the SuZuKi reaction, the borated Ar 1 The compound is coupled with the fluorenyl tertiary alcohol obtained in the S1 step to prepare a compound with Ar 1 The tertiary alcohol compound of the electron donor, as a ring-closing precursor;

[0057] S3: the ring-closing precursor Ar obtained in the step S2 1 For tertiary alcohol compounds, the Friedel-Crafts ring closure reaction is carried out under the environment of normal temperature and organic acid to prepare nano-corner-cut lattices;

[0058] S4: The nano-cornered lattice obtained in the step S3 is subjected to an aromatic nucleophilic reaction with...

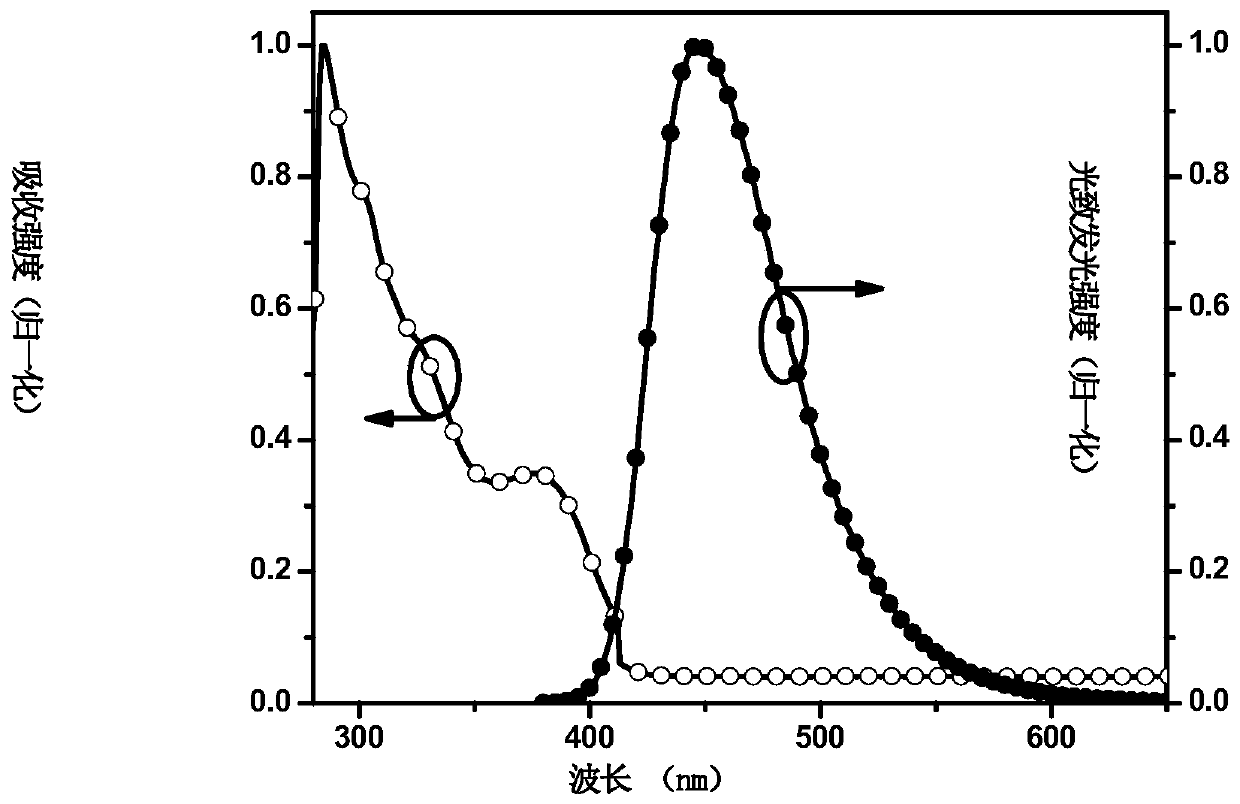

Embodiment 6

[0088] All spin-coating and annealing processes were performed in air atmosphere. Before spin coating, the ITO substrates were cleaned as follows: in each detergent, ultrapure H 2 Ultrasound in O (twice), acetone, ethanol for 10 minutes; UV-O 3 Irradiate for more than 15 minutes. PEDOT:PSS was dissolved in ultrapure H at a ratio of 1:1 wt%. 2 O, and spin-coated on a clean ITO substrate at 4000 rpm for 30 s and annealed at 150 °C for 10 min. in N 2 After cooling for 5 minutes under ambient conditions, on the PEDOT:PSS layer, spin-coat a 10 mg / mL DTrz-Cz-Grid toluene solution at a speed of 2200 rpm to form a light-emitting layer. The spin-coating time is 30 seconds, and annealed at 100°C for 10 minutes. , and use N 2 After flow cooling for 5 minutes, use vapor deposition equipment (SE-4260, ALS Technology, Japan) to form TmPyPb (50nm), LiF (1nm) and Al (120nm) on the upper layer of the light-emitting layer by vacuum deposition, and the pressure of vapor deposition 4 Pa, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com