Waterproof and fireproof thermal insulation wall

A technology for fire prevention and heat preservation and wall body, which is applied in the fields of heat preservation, fire prevention, and building heat preservation materials, etc. It can solve the problems of single function and troublesome operation, and achieve the effect of improving extraction efficiency, reducing water absorption rate and reducing moisture return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

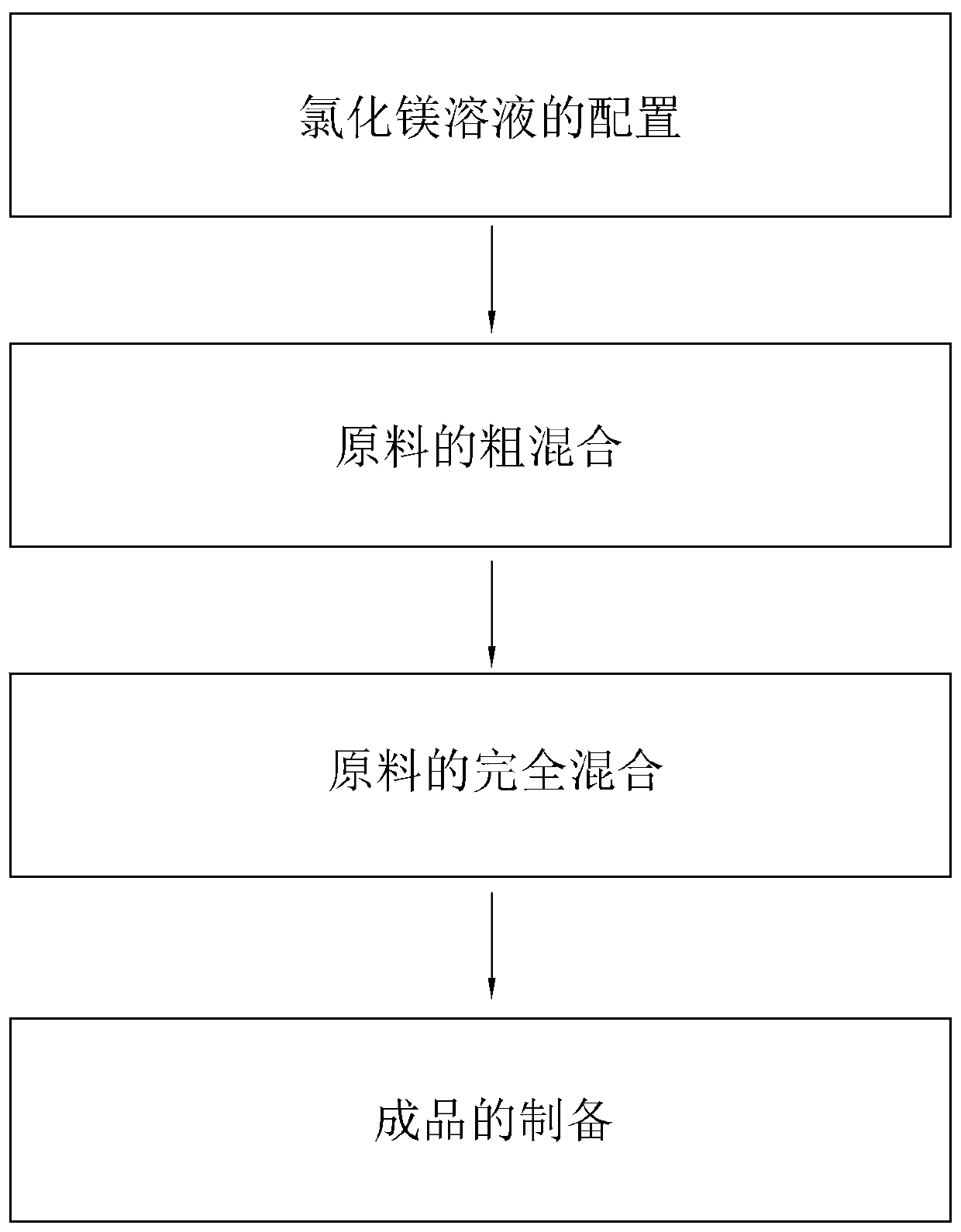

[0049] A waterproof and fireproof insulation wall, the raw material components are shown in Table 1 in parts by weight. Wherein, the preparation method of the waterproof and fireproof insulation wall comprises the following steps:

[0050] Step 1, configuration of magnesium chloride solution: dissolve magnesium chloride with water, firstly dissolve magnesium chloride at a ratio of 1 part of magnesium chloride to 1 part of water, and then add water until the Baume degree is between 26-30, so that sodium chloride and impurities are precipitated in the At the bottom, take the upper clarified liquid;

[0051] Step 2, rough mixing of raw materials: adding polyethylene glycol, sodium dodecylsulfonate, cetyltrimethylammonium bromide, phosphoric acid, silicone water repellent, ferrous sulfate, citric acid to magnesium chloride solution in, stir evenly;

[0052] Step 3, complete mixing of raw materials: continue to add magnesium oxide, expanded perlite, fly ash, hollow glass microsph...

Embodiment 2

[0056] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com