Novel mobile phone back cover and production process thereof

A mobile phone back cover, a new technology, applied in layered products, other household appliances, synthetic resin layered products, etc., can solve the problem of low efficiency of sheet transfer and PVD coating, low product yield, large odor and bubble point and other problems, to achieve the effect of reducing scratch defects, improving product yield, and good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

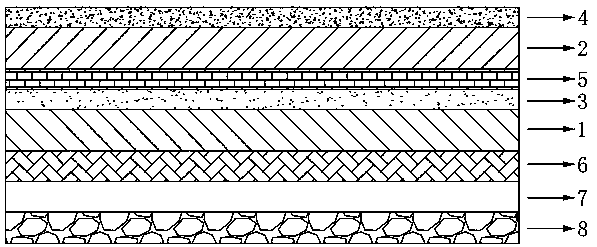

[0053] Such as figure 1 As shown, a new type of mobile phone back cover includes an explosion-proof base material layer 1 and a PC sheet layer 2. The explosion-proof base material layer 1 is an aliphatic TPU film formed by tape casting or coating or is coated with acrylic resin and subjected to UV The acrylic resin film formed by curing or PC substrate, the explosion-proof substrate layer 1 is coated with an adhesive layer 3 formed of acrylic pressure-sensitive adhesive or hot melt adhesive, and one side of the PC sheet layer 2 is coated with a hardened layer 4 , the other side of the PC board layer 2 is coated with a layer of water vapor barrier coating 5 and compounded with the adhesive layer 3 .

[0054] The new mobile phone back cover provided by the above embodiment, because the explosion-proof base material layer is an aliphatic TPU film formed by tape casting or coating, or an acrylic resin film coated with acrylic resin and formed by UV curing, or a PC base material, ...

Embodiment 2

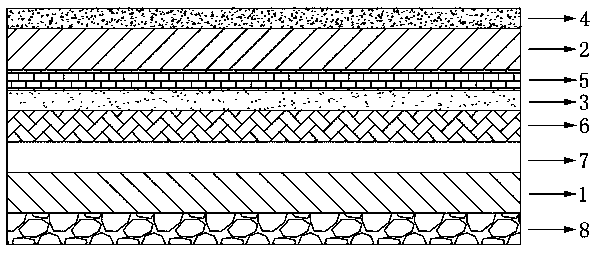

[0069] Such as figure 2 As shown, the difference between the novel mobile phone rear cover provided in this embodiment and the novel mobile phone rear cover in Embodiment 1 is only the difference in the surface structure of the explosion-proof base material layer 1, and the lower layer of the explosion-proof base material layer 1 in the present embodiment A layer of UV ink silk screen printing layer 8 is formed on the surface by UV ink silk screen printing, and a layer of PVD brightening layer 7 is formed on the upper surface of the explosion-proof substrate layer 1 by sputtering, and a layer of PVD brightening layer 7 is formed on the upper surface of PVD brightening layer 7 by UV transfer printing texture. The UV transfer layer 6 , the adhesive layer 3 is coated on the UV transfer layer 6 .

[0070] As another aspect of this embodiment, a new mobile phone back cover production process includes the following steps:

[0071] a) The aliphatic TPU film formed by tape casting o...

Embodiment 3

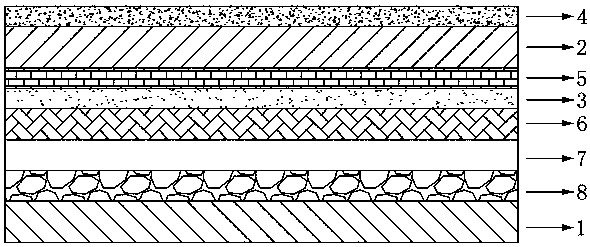

[0082] Such as image 3 As shown, the difference between the novel mobile phone rear cover provided in this embodiment and the novel mobile phone rear cover in Embodiment 1 is only the difference in the surface structure of the explosion-proof base material layer 1, and the upper layer of the explosion-proof base material layer 1 in the present embodiment A layer of UV ink silk screen printing layer 8 is formed on the surface by UV ink silk screen printing, and a layer of PVD brightening layer 7 is formed on the upper surface of UV ink screen printing layer 8 by sputtering, and a layer of PVD brightening layer 7 is formed on the upper surface of PVD brightening layer 7 by UV transfer printing texture. The UV transfer layer 6 , the adhesive layer 3 is coated on the UV transfer layer 6 .

[0083] As another aspect of this embodiment, a new mobile phone back cover production process includes the following steps:

[0084] a) The aliphatic TPU film formed by tape casting or coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com