Monolithic visible light catalytic material and preparation method thereof

A catalytic material, visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve problems such as unfavorable recycling, high photocatalytic activity, difficult to maintain, etc. Simple, easy-to-control, and easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

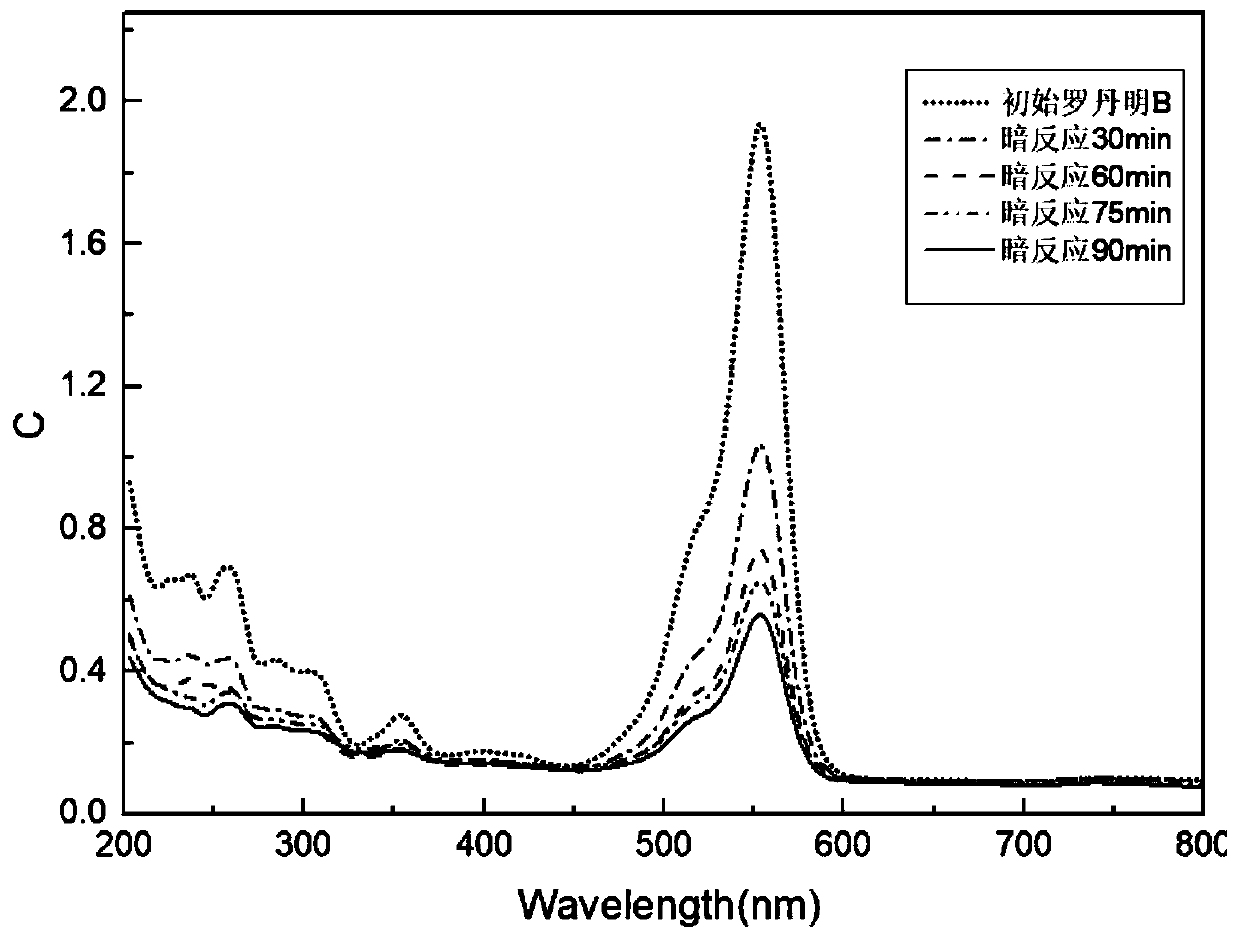

Image

Examples

Embodiment 1

[0023] A monolithic visible photocatalytic material and a preparation method thereof, which are realized according to the following steps:

[0024] (1) Preparation of zirconium oxychloride precursor solution: Weigh 1.5g of zirconium oxychloride, measure 5mL of acetylacetone and 2mL of hydrogen peroxide, and use 20mL of absolute ethanol as a solvent to mix zirconium oxychloride, acetylacetone, Dissolve hydrogen peroxide in absolute ethanol, and stir evenly to obtain a zirconium oxychloride precursor solution;

[0025] (2) Preparation of boric acid solution: Take a certain mass of boric acid according to the molar ratio of zirconium oxychloride to boric acid being 1:6, dissolve boric acid in 20mL of absolute ethanol, heat and stir in a water bath at 60°C for 15min to obtain a boric acid solution.

[0026] (3) Preparation of glucose solution: according to zirconium oxychloride, glucose mass ratio is 3:1, take the glucose of certain quality, dissolve glucose in 20mL deionized wate...

Embodiment 2

[0035] A monolithic visible photocatalytic material and a preparation method thereof, which are realized according to the following steps:

[0036] (1) Preparation of zirconium oxychloride precursor solution: Weigh 1g of zirconium oxychloride, measure 2mL of acetylacetone and 1.5mL of hydrogen peroxide, and use 15mL of absolute ethanol as a solvent to mix zirconium oxychloride, acetylacetone, Dissolve hydrogen peroxide in absolute ethanol, and stir evenly to obtain a zirconium oxychloride precursor solution;

[0037] (2) Preparation of boric acid solution: Take a certain mass of boric acid according to the molar ratio of zirconium oxychloride and boric acid being 1:5, dissolve boric acid in 20mL of absolute ethanol, heat and stir in a water bath at 60°C for 15min to obtain a boric acid solution.

[0038] (3) Preparation of glucose solution: according to the mass ratio of zirconium oxychloride and glucose of 1:1, a certain amount of glucose was weighed, and the glucose was diss...

Embodiment 3

[0043] A kind of integral visible light catalytic material and preparation method thereof are realized according to the following steps:

[0044] (1) Preparation of zirconium oxychloride precursor solution: Weigh 1.2 g of zirconium oxychloride, measure 3 mL of acetylacetone, 2 mL of hydrogen peroxide, use 20 mL of absolute ethanol as a solvent, mix zirconium oxychloride, acetylacetone, Dissolve hydrogen peroxide in absolute ethanol, stir evenly to obtain zirconium oxychloride precursor solution;

[0045] (2) Preparation of boric acid solution: according to the molar ratio of zirconium oxychloride and boric acid as 1:8, a certain mass of boric acid was weighed, and the boric acid was dissolved in 25 mL of absolute ethanol, heated and stirred in a 60°C water bath for 15 min to obtain a boric acid solution.

[0046] (3) preparation of glucose solution: according to zirconium oxychloride, glucose mass ratio is 4:1 to take by weighing a certain quality of glucose, glucose is dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com