Preparation method of full nutrition formula food

A technology of formula food and complete nutrition, which is applied in the field of preparation of complete nutrition formula food, can solve the problem that the mixing uniformity of complete nutrition formula powder cannot meet the requirements, and achieve the effect of stable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

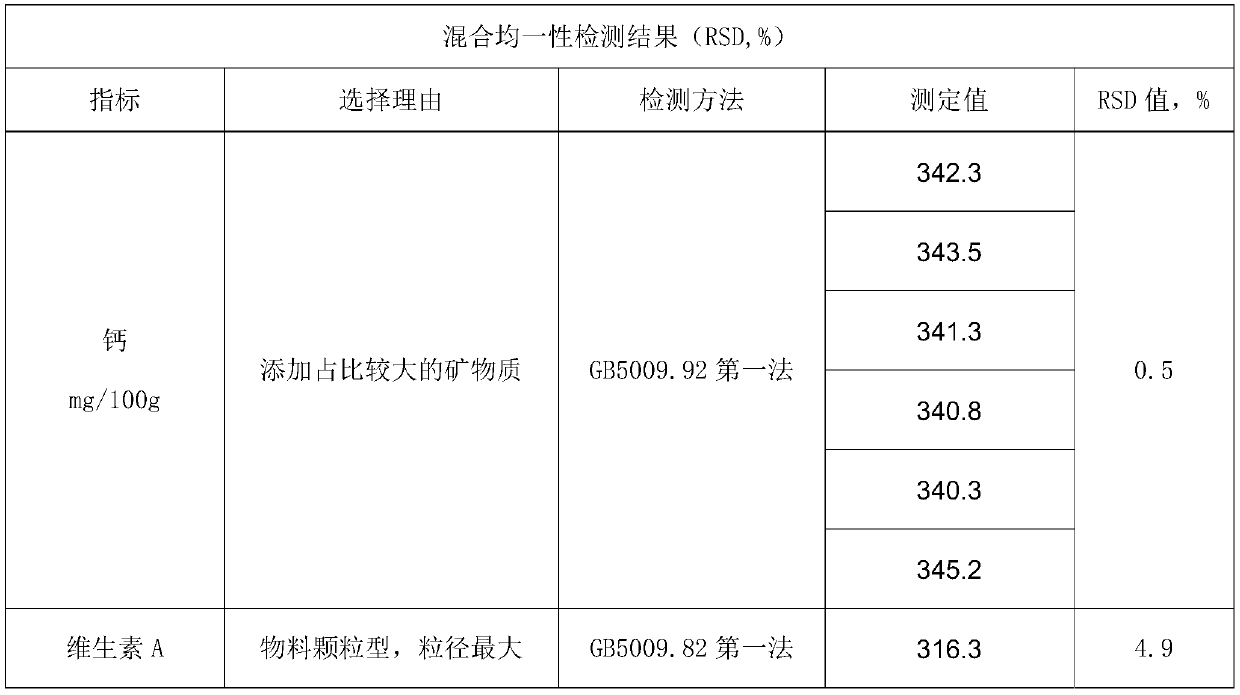

Examples

Embodiment 1

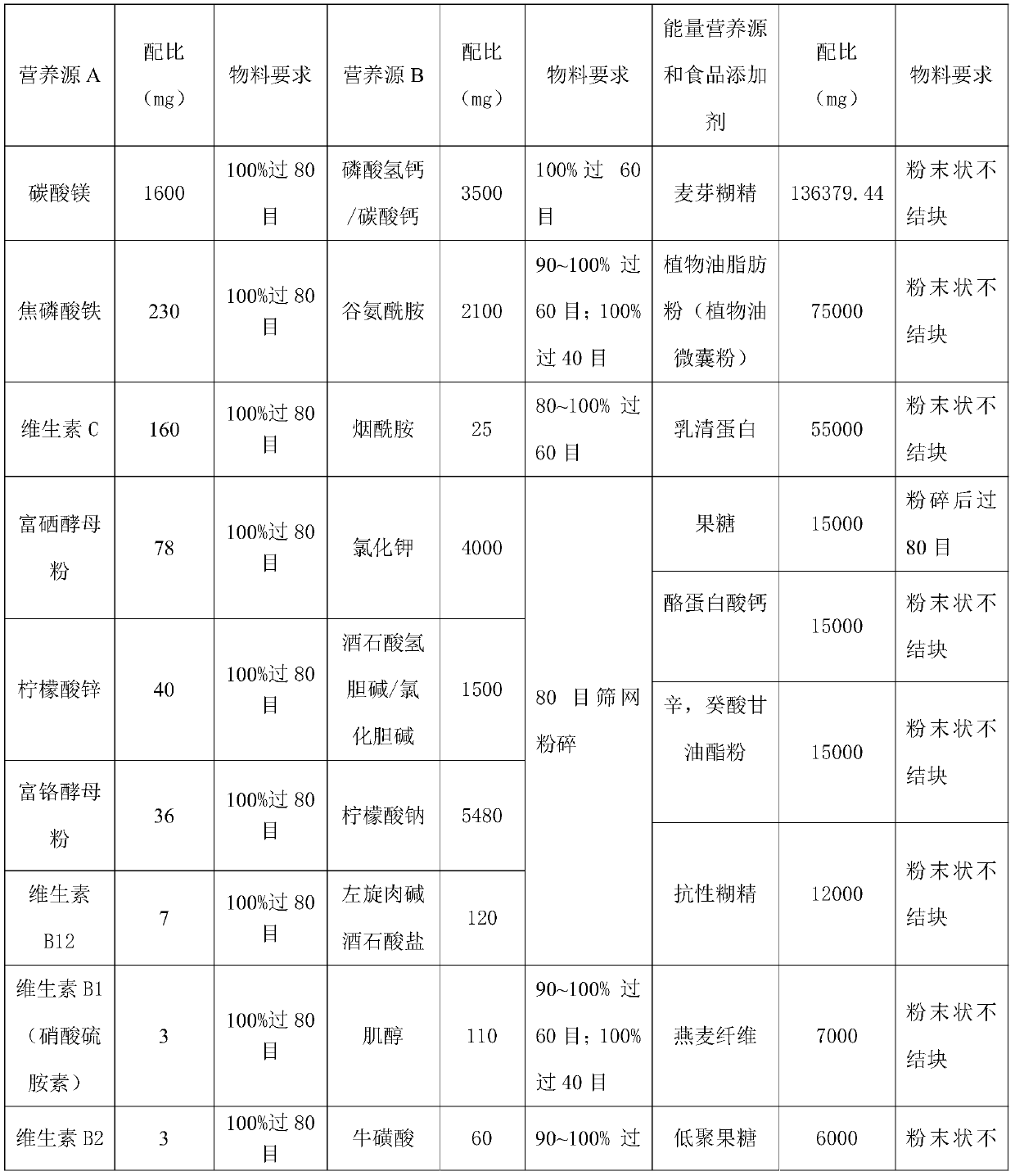

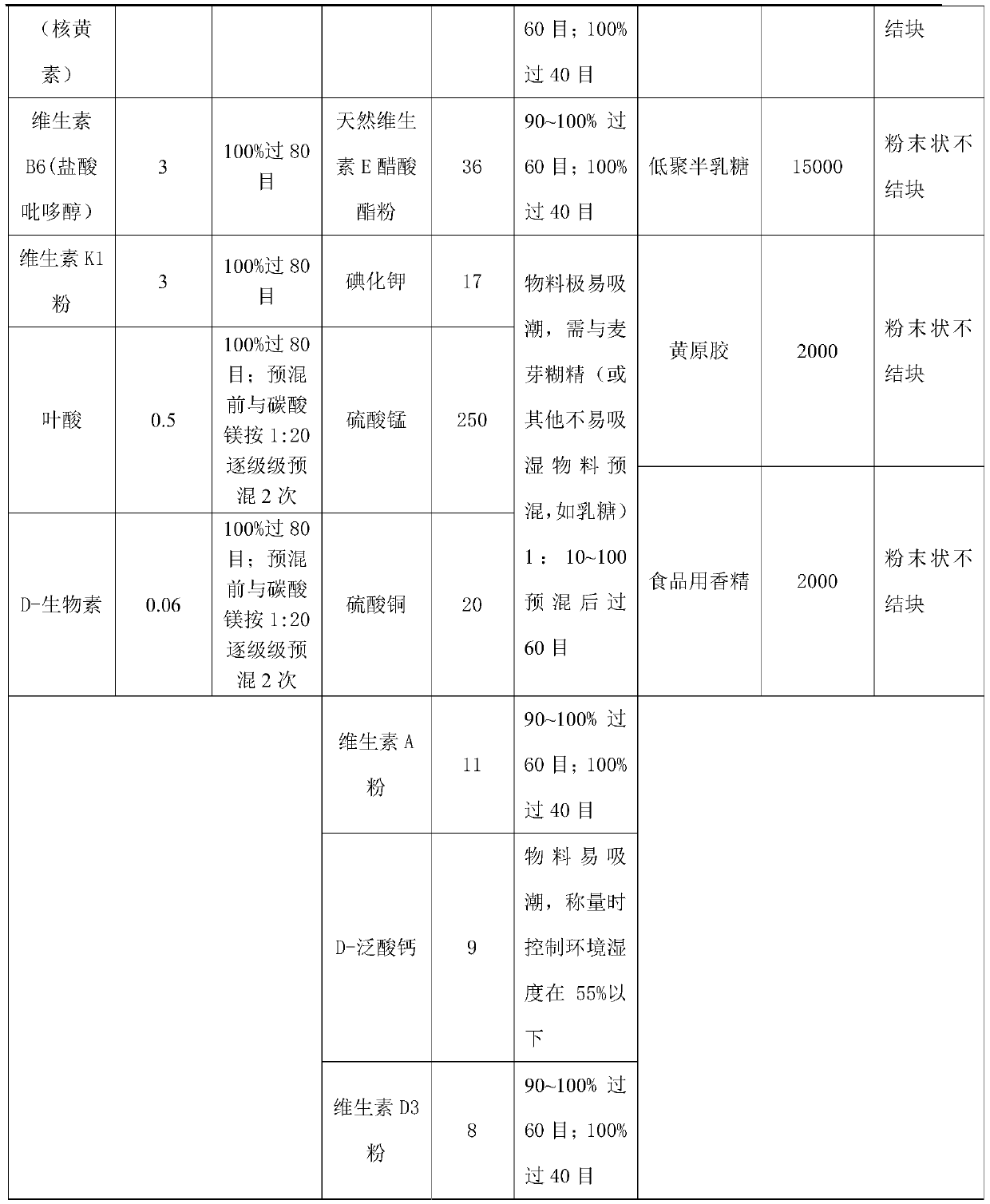

[0026] 1. The product formula is shown in Table 1 below:

[0027] Table 1 raw material components and proportioning

[0028]

[0029]

[0030] 2. A method for preparing a nutritionally complete formula food, comprising the following steps:

[0031] (1) The ratio of materials, control requirements and pretreatment shall be processed according to the requirements of Table 1, among which:

[0032] All materials of nutrient source A are required to pass 100% through an 80-mesh sieve; folic acid and D-biotin are premixed with magnesium carbonate at a ratio of 1:20 for 2 times step by step before mixing;

[0033] The materials of calcium hydrogen phosphate or calcium carbonate, glutamine, niacinamide, inositol, taurine, natural vitamin E acetate powder, vitamin A and vitamin D3 in nutrient source B require that 90-100% of them pass through a 60-mesh sieve and 100% pass through a 40-mesh sieve; potassium iodide, manganese sulfate, choline bitartrate or choline chloride and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com