Multi-stage themolysis coupled denitration method using front flow field uniformizing device and device thereof

A uniform and flow field technology, applied in the field of multi-stage pyrolysis coupled denitrification method and its device, can solve the problems of difficulty in controlling ammonia escape, large initial investment and high operating cost, saving reducing agent injection system, improving utilization rate, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

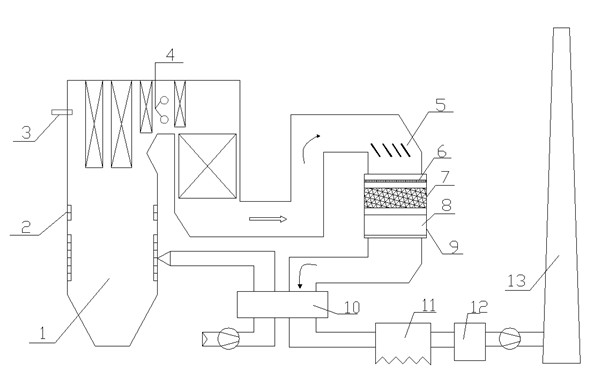

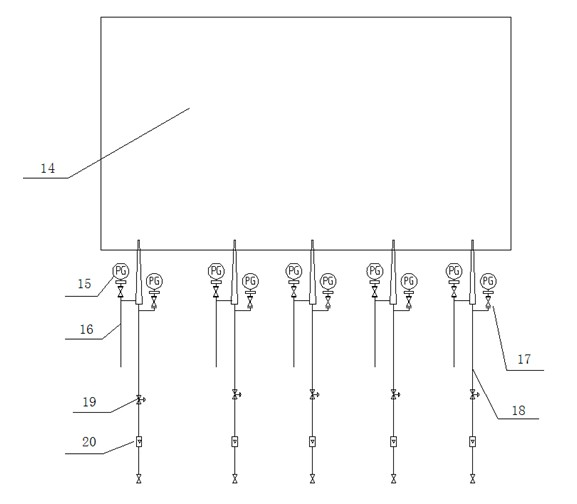

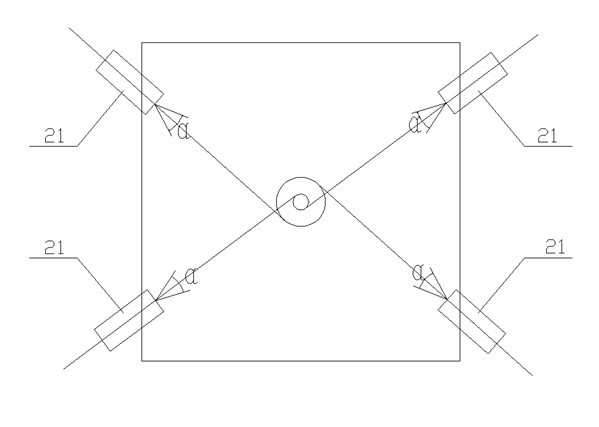

[0026] The following is a further detailed description of the multi-stage pyrolysis coupling denitrification method with a pre-flow field uniform device according to the accompanying drawings and specific examples.

[0027] Such as Figure 1 to Figure 3 As shown, in the invented multi-stage pyrolysis coupling denitrification device, a pre-flow field uniform device is provided on the boiler furnace, more than one layer of reducing agent ammonia replenishment spray guns are fixedly arranged on the boiler front wall, and a boiler horizontal flue is arranged Ammonia supplementation spray gun for reductant above the first floor, and SCR reactor with SCR catalyst fixedly installed at the tail flue of the boiler. As a preferred solution of the present invention, the front flow field uniform device is a swingable tuyere arranged on the furnace of the boiler. In particular, it is preferable that the reducing agent ammonia replenishing spray gun 3 is arranged at the position where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com