Method for producing organic compost fertilizer

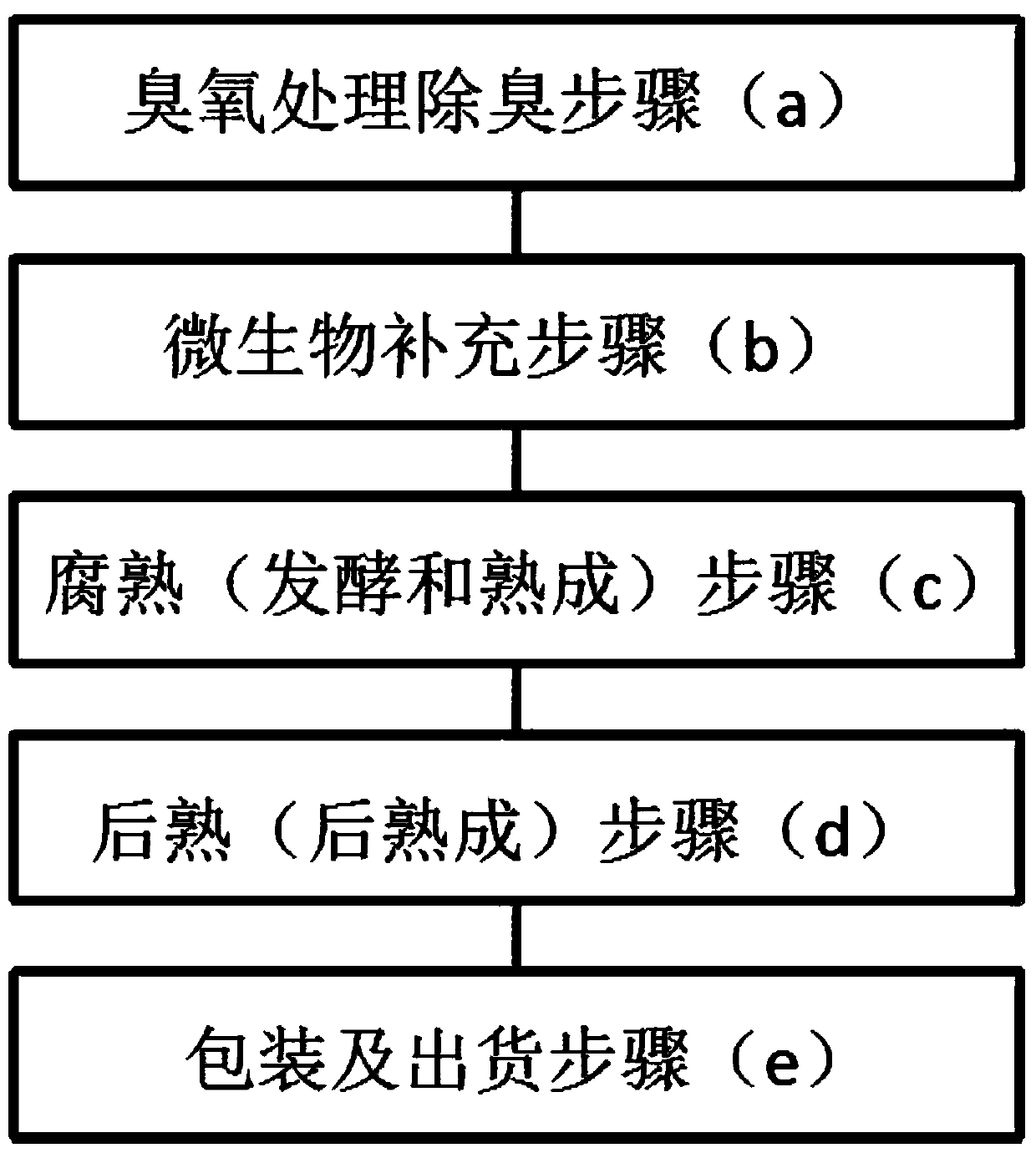

A technology of organic composting and production methods, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts. It can solve the problems of odor reduction, corruption, and low-quality composting, and achieve the effect of reducing odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

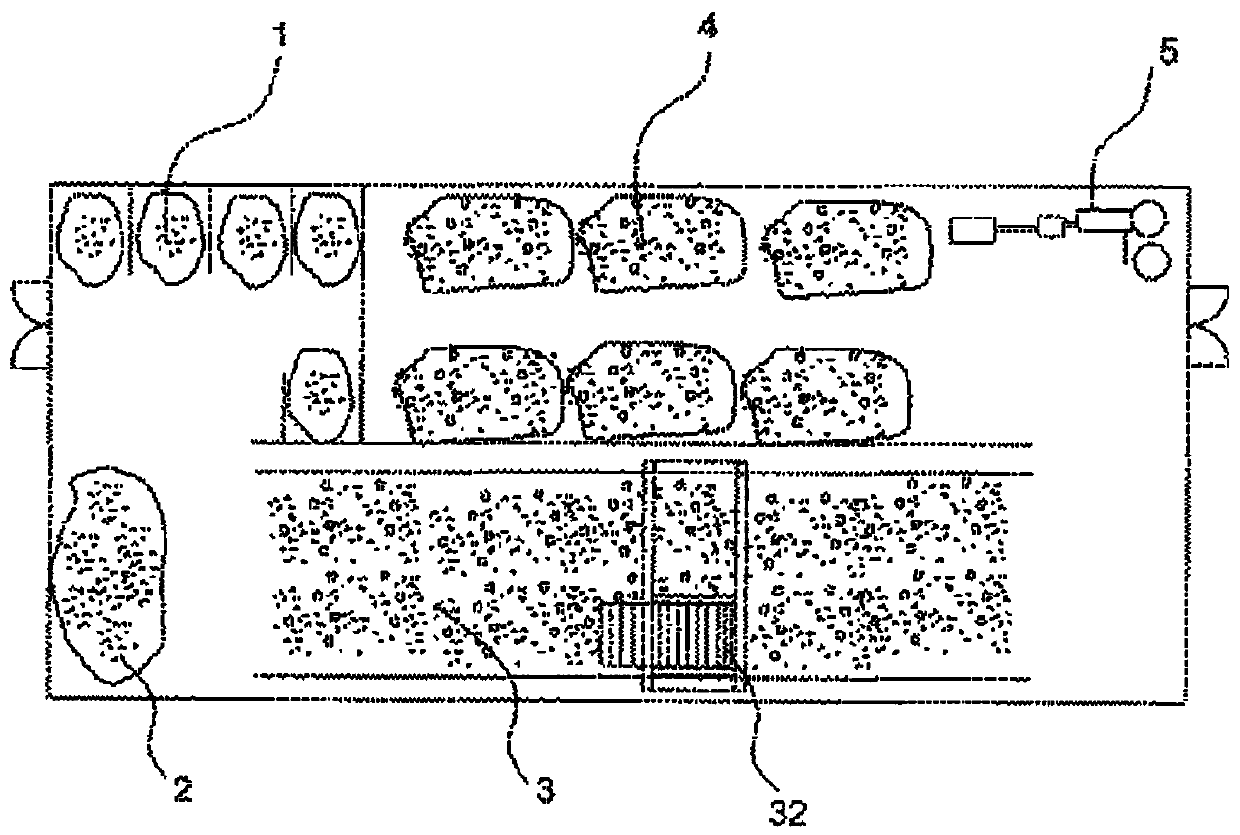

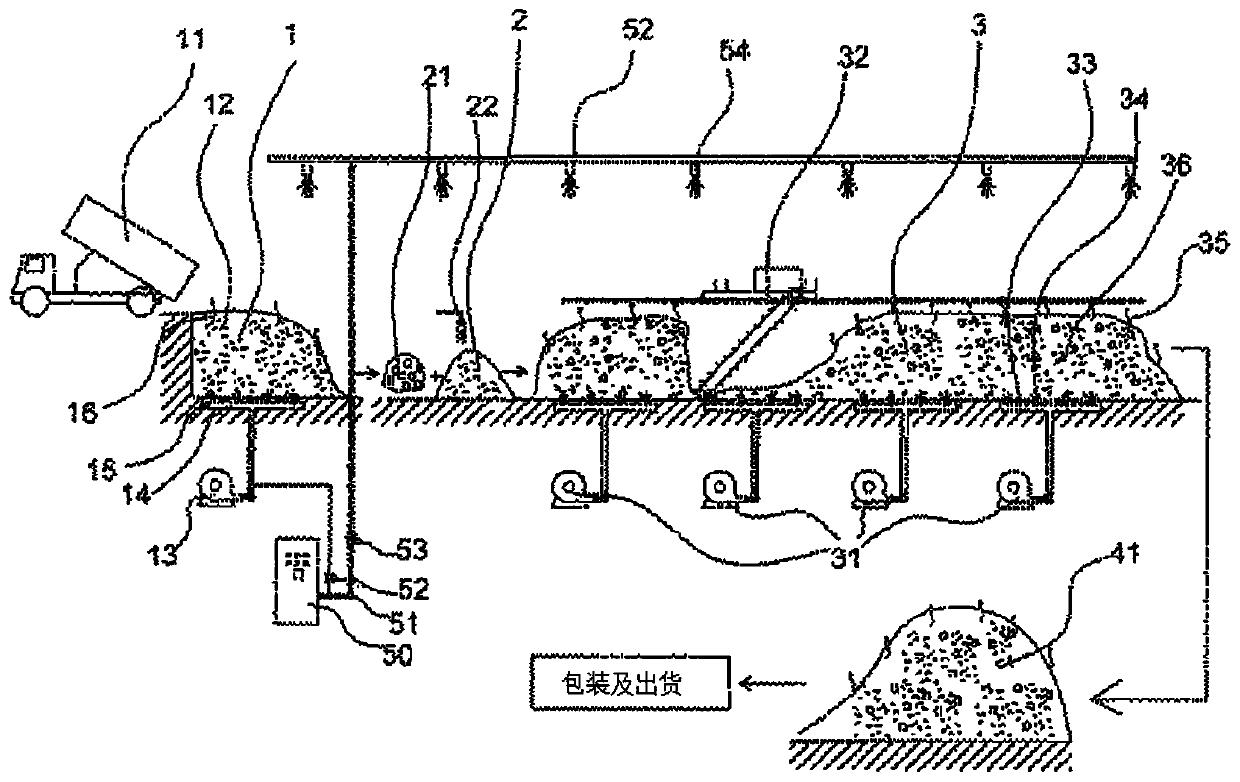

Method used

Image

Examples

Embodiment 1

[0080]

[0081] In the first step of ozone treatment for compost raw materials, for the livestock manure stored in the organic composting production facility of 70-100 tons of livestock manure per day, on the ground of the ozone treatment site, in order to make the ozone (O 3 ) circulation, set the ventilation pipe of the ozone treatment field with air holes, the ventilation pipe of the ozone treatment field is connected with the fan of the ozone treatment field and the ozone generator, the air volume sent by the ozone generator is small and the wind pressure is low, so it is not enough to make it loaded in the ozone treatment Because the livestock manure in the field passes through, the ozone with an ozone concentration of 100ppm is sent out by a fan with a high pressure and a large air volume, thereby removing the odor of the livestock manure with a strong odor.

[0082] In addition, ozone is also decomposed with organic substances through an oxidation reaction, thereby bec...

Embodiment 2

[0089]

[0090] In the first step of ozone treatment of food waste, for the food waste stored in the food waste composting production facility of 50 tons of food waste per day, on the ground of the vertical fermenter (ozone treatment field), in order to make the ozone (O 3 ) circulation, set the ventilation pipe of the ozone treatment field with air holes, the ventilation pipe of the ozone treatment field is connected with the fan of the ozone treatment field and the ozone generator, the air volume sent by the ozone generator is small and the wind pressure is low, so it is not enough to make it loaded in the ozone treatment Food waste from the farm passes through. Therefore, a fan with a high pressure and a large air volume sends out ozone with an ozone concentration of 70ppm to remove the odor of food waste with a strong odor.

[0091] In addition, ozone also undergoes oxidation reactions with organic substances. In particular, the smell of food waste is different from tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com