Fabrication method of slice cell, slice cell and photovoltaic module

A battery and slicing technology, applied in the field of solar energy utilization, can solve the problems of slicing battery efficiency loss, efficiency loss restricting the development of photovoltaic module technology, photovoltaic module power loss, etc., to achieve the effect of improving photoelectric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In order to solve the technical problem of efficiency loss of sliced batteries, the present invention provides a preparation method of sliced batteries, sliced batteries and photovoltaic modules.

[0027] In the first embodiment provided by the present invention, the method for preparing a sliced battery includes the following steps:

[0028] S101. After scribing and splitting the whole battery by laser, a plurality of independent sub-cells are obtained, and the sub-cells have at least one fracture surface.

[0029] The entire battery is scribed at the preset position by laser to obtain a groove-shaped scribe. At this time, only the scribe is formed on the surface of the entire battery, and the entire battery is not separated from the groove-shaped scribe position. Open to form multiple independent sub-cells; the groove-shaped slits provide guidance for subsequent slivers, that is, when mechanical slitting is used, the entire battery will be split along the slit...

Embodiment 1

[0061] S101. Take a whole piece of HIT battery, and the whole piece of HIT battery has a transparent conductive oxide layer on it. The entire HIT battery is sliced by laser at a preset position, wherein the preset position is between the two main grid lines and parallel to the main grid lines; After processing, a HIT cell with 5 busbar half-cut patterns is formed.

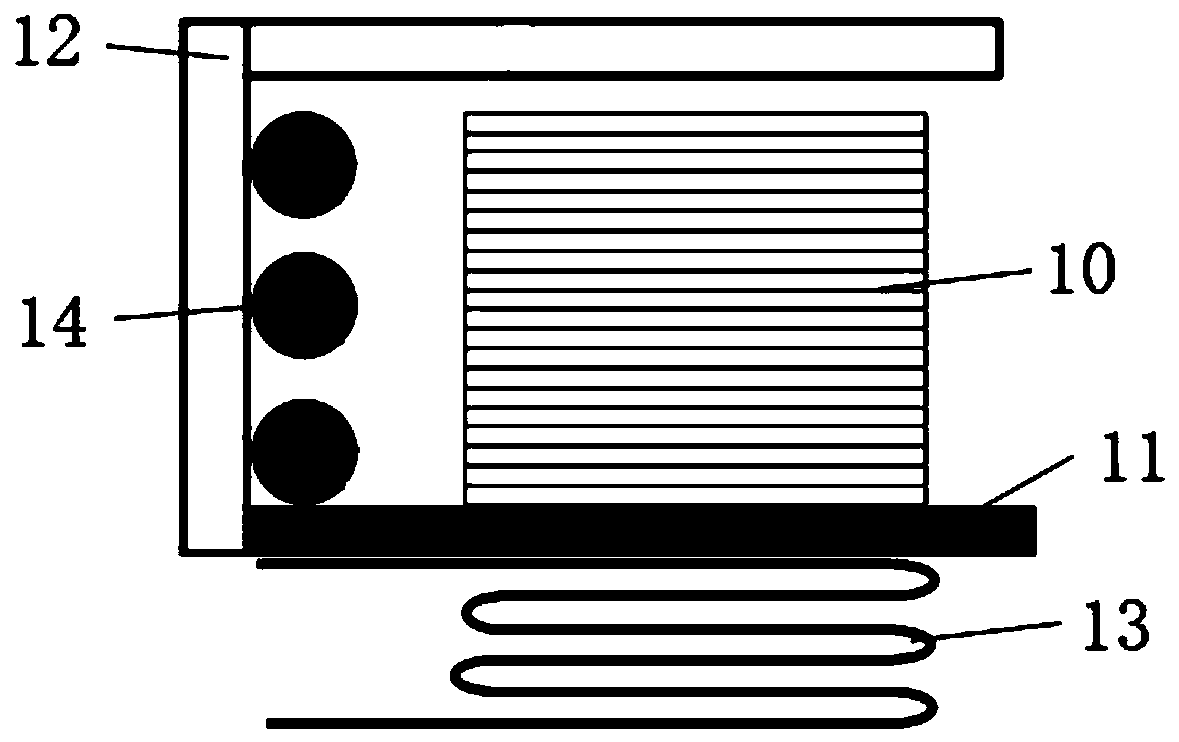

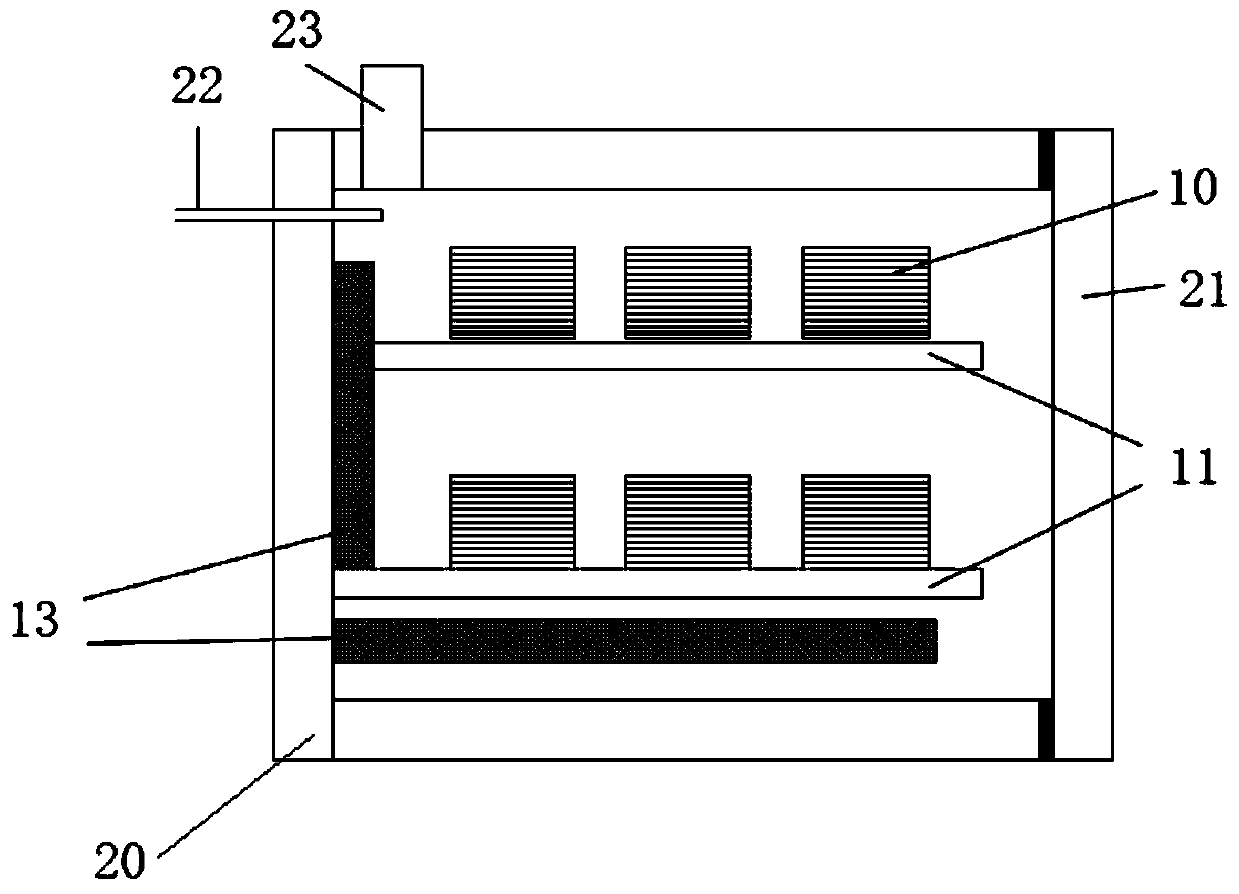

[0062] S102. Stack and place the 5 busbar half-cut graphic HIT cells in sequence on the hollow tray 11 (for details, refer to figure 1 ), push into the annealing station, under the static air environment, turn on the heater 13 and the infrared heating lamp tube 14 in the heat insulation frame 12, and heat the HIT battery sheet of the 5 busbar half-sheet pattern, and the heating time is 30 minutes, 5 The temperature on the surface of the busbar half pattern HIT cell is controlled at 200 degrees Celsius.

[0063] S103. After the heating time is over, push out the tray 11 carrying the HIT cells with 5 busbar half-...

Embodiment 2

[0066] S101. Scribing the entire PERC battery sheet at a preset position with a laser. The preset position is between two busbars and parallel to the busbars; After the slitting process, the independent 5-busbar half-cut pattern PERC cells are formed;

[0067] S102. Stack and place PERC cells with 5 busbar half-cut patterns on the hollowed-out tray 11 (for details, refer to figure 1 ), push into the annealing station, and under the static air environment, turn on the heater 13 and the infrared heating lamp tube 14 in the heat insulation frame 12, and heat the PERC cells with 5 main grid half-sheet patterns, and the heating time is 30 minutes, 5 The temperature on the surface of the busbar half pattern PERC cell is controlled at 200 degrees Celsius.

[0068] S103 , after the heating time is over, push out the tray 11 carrying the PERC cells with 5 busbar half-cut patterns from the annealing station and cool down to room temperature.

[0069] The obtained sliced battery is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com