Long-spray-pipe shock wave soot blower with functions of cooling and preventing soot accumulation

A shock wave soot blower and shock wave generator technology, applied in the field of long nozzle shock wave soot blowers, can solve the problems of shortening service life, affecting heat transfer, and dust accumulation, so as to prolong service life and achieve uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

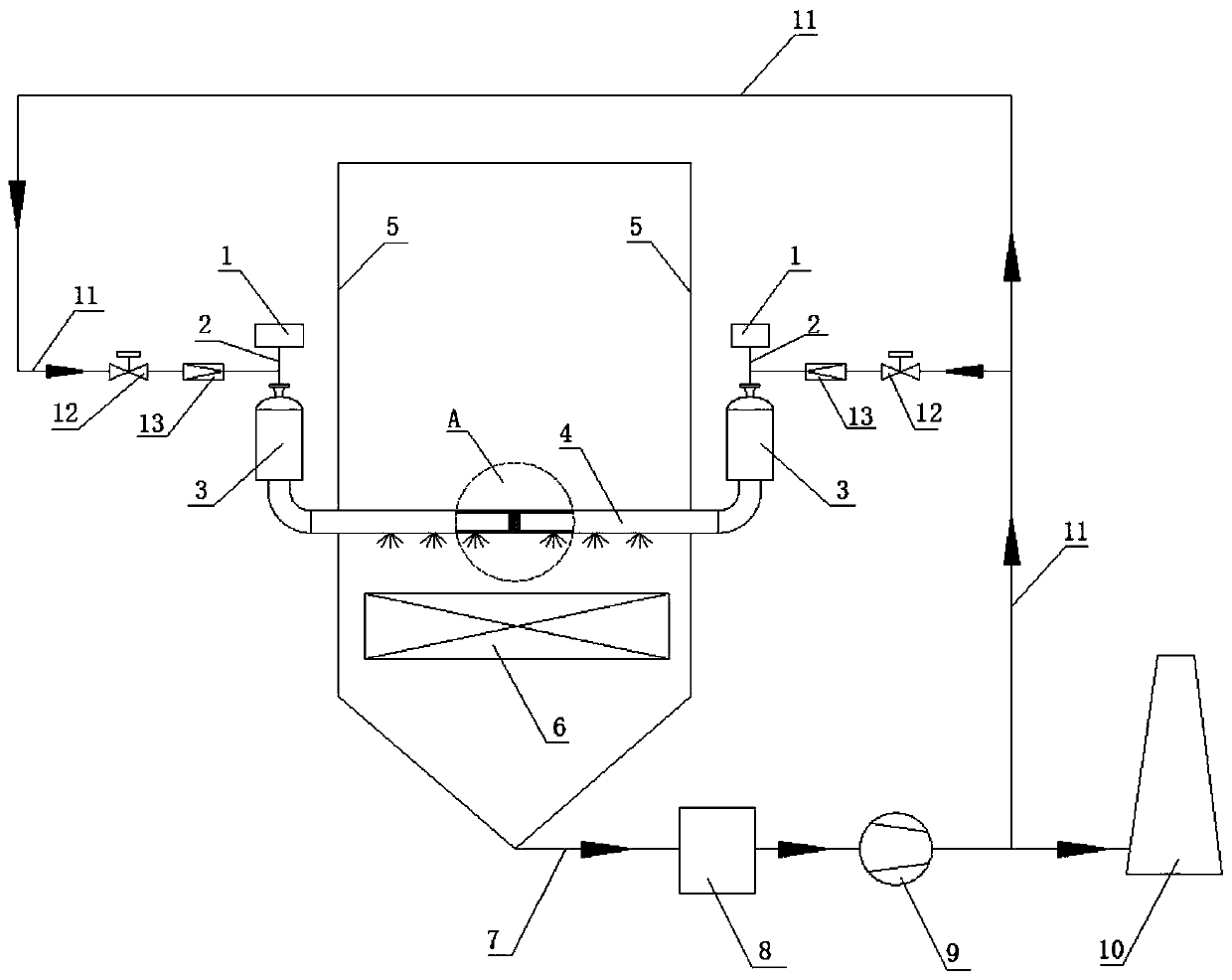

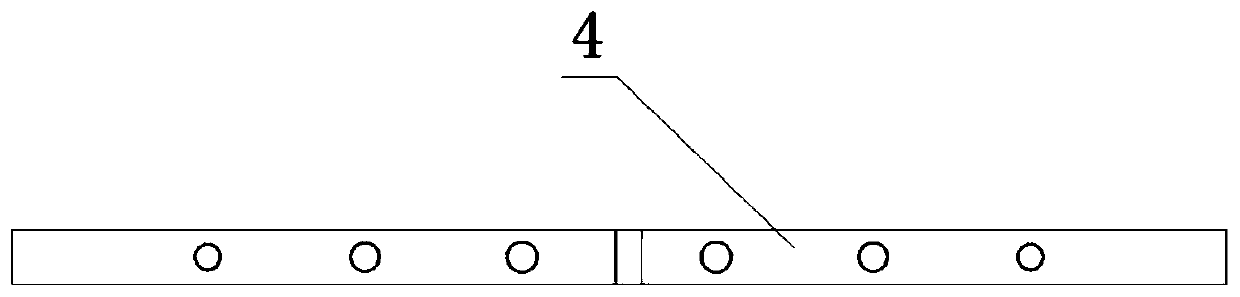

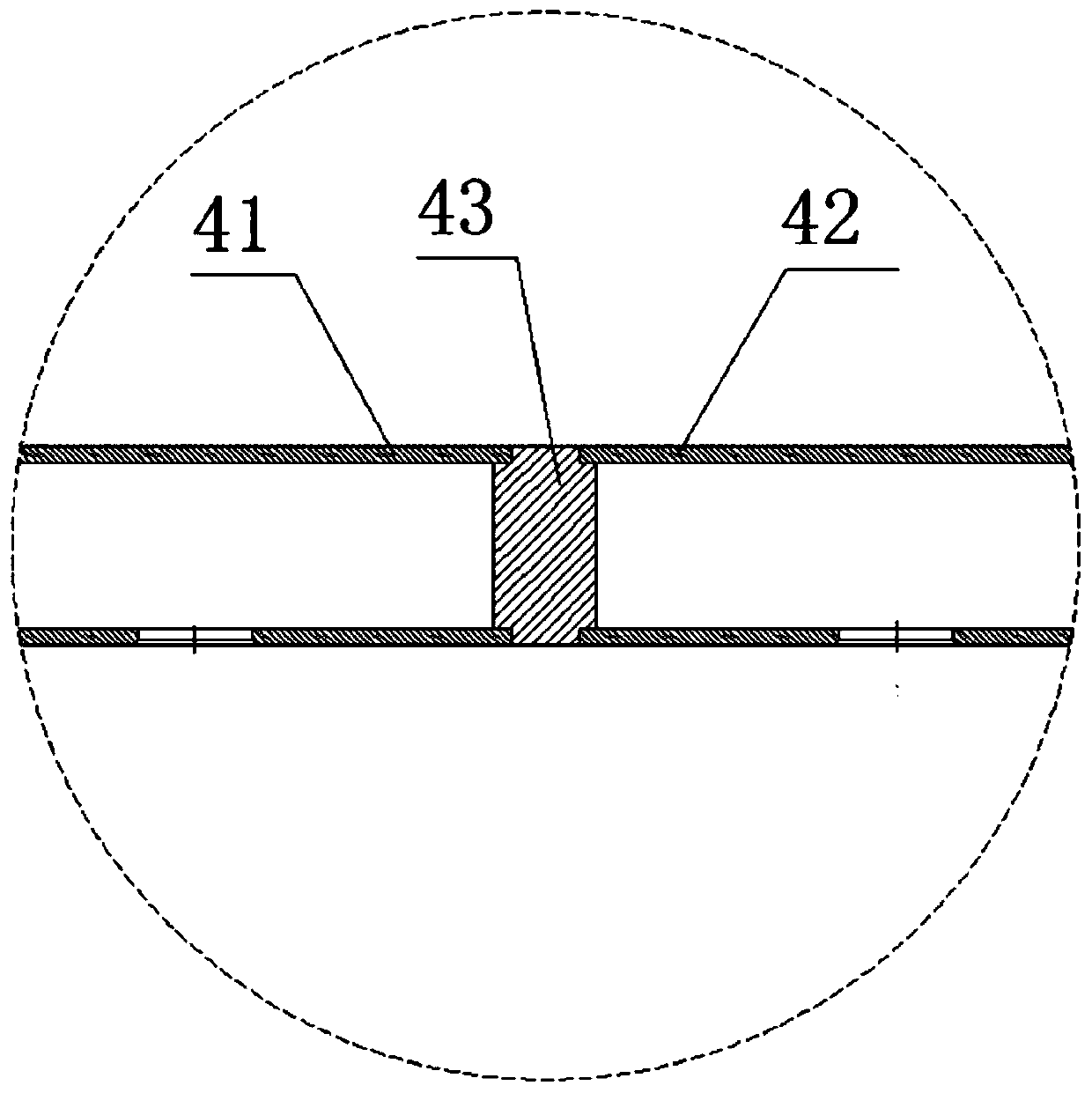

[0022] specific embodiment Figure 1 to Figure 3 As shown, the present invention includes a gas distribution ignition device 1, an ignition pipeline 2, a shock wave generator 3, a long nozzle 4, a furnace wall 5, a convective heat exchange tube bundle 6, a flue gas pipeline 7, a flue gas dust removal and purification system 8, an induction Fan 9, chimney 10, clean flue gas pipe 11, clean flue gas control valve 12, clean flue gas check valve 13, gas distribution ignition device 1 is connected with shock wave generator 3 through ignition pipe 2, and two shock waves are generated The device 3 is symmetrically arranged; the gas outlet of the shock wave generator 3 is connected with the gas inlet of the long nozzle 4, the long nozzle 4 runs through the furnace wall 5 and is arranged in the flue, and the long nozzle 4 consists of a left nozzle 41 which is left and right symmetrical. , the right nozzle 42 and the rigid connecting column 43 are welded, and the bottoms of the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com