Device and method for regulating and controlling fly ash deposition layer based on impinging stream technology

A technology of deposition layer and impinging flow, which is applied in the direction of combustion method, lighting and heating equipment, removal of solid residue, etc., can solve the problem of ash in the heating area of the boiler, and achieve the effects of improving efficiency, facilitating regulation, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Based on the ash problem in the heating area of the boiler when using high-alkali coal such as Zhundong coal, this example proposes a method to control the fly ash deposition layer. The surface of coal fly ash is coated with nanoparticles, so that the fly ash particles are modified. By coating the surface of high-alkali coal-burning fly ash with nanoparticles, the surface viscosity can be effectively reduced, and the structure and composition of the fly ash deposition layer can be regulated, so as to significantly improve the ash deposition problem.

Embodiment 2

[0034] Specifically, the method for controlling the fly ash deposition layer in this embodiment uses impinging flow technology to coat the surface of the high-alkali coal-fired fly ash with nanoparticles, and the nanoparticles can be preferably SiO2 according to the situation. 2 、Al 2 o 3 、TiO 2 or kaolin.

Embodiment 3

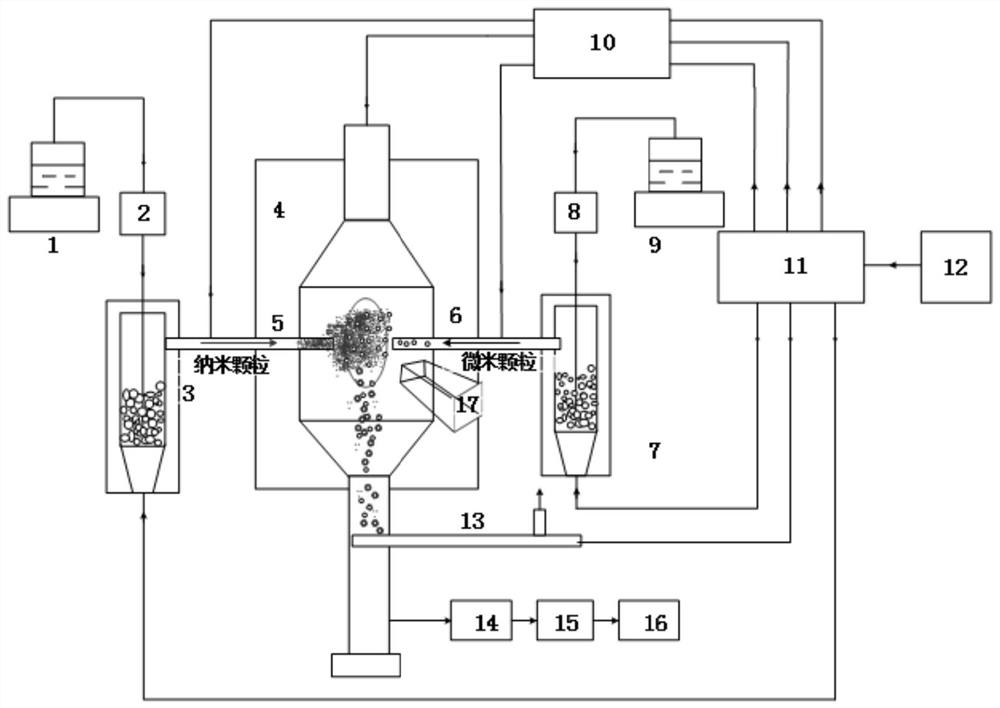

[0036] Such as figure 1 As shown, the device for controlling the fly ash deposition layer based on impinging flow technology in this embodiment includes a high-temperature furnace 4, a nanoparticle injection system and a fly ash injection system, and the nanoparticle injection system and the fly ash injection system are respectively used to inject Nanoparticles and micron fly ash are sprayed inside the high-temperature furnace 4, and the spraying directions are set oppositely. Specifically, the nanoparticle injection system includes a nanoparticle nozzle 5 and a nanoparticle feeding unit, the fly ash injection system includes a fly ash particle nozzle 6 and a fly ash feeding unit, the nanoparticle nozzle 5 and the fly ash particle nozzle 6 The discharge ends of all extend into the interior of the high-temperature furnace 4 and are relatively arranged. The nanoparticles and fly ash are fed through the nanoparticle feeding unit and the fly ash feeding unit respectively, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com