Reinforced concrete combined box girder with steel tube-steel plate combined web

A technology of combining webs and combined boxes, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of loss of longitudinal prestress of concrete structures, waste of materials, and difficulty in welding, avoiding the problem of web cracking, and facilitating on-site Construction, the effect of improving application efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

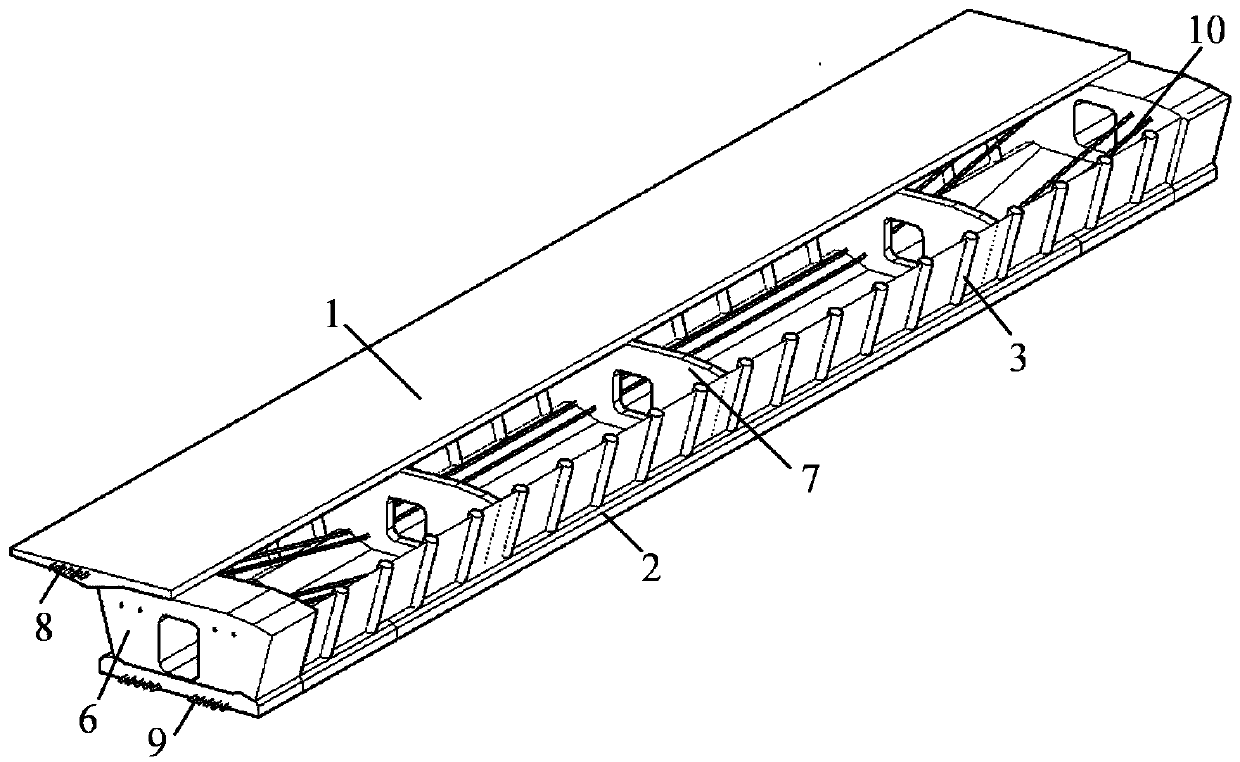

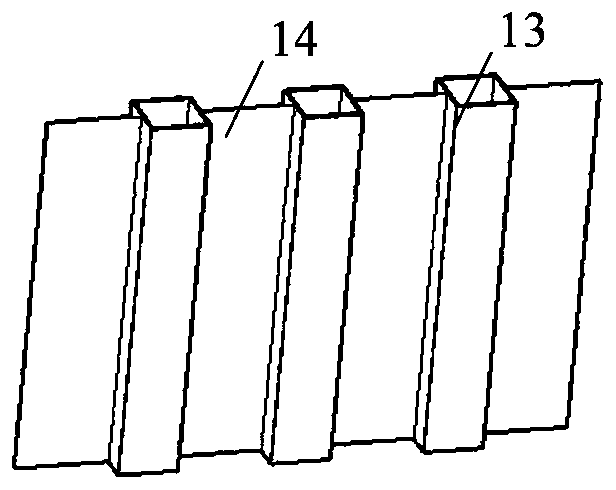

[0033] Such as Figure 1-7 As shown, this embodiment provides a steel-steel-steel composite web steel-concrete composite box girder, including a concrete roof 1, a concrete floor 2, a steel pipe-steel composite web 3, an upper flange steel plate 4, a lower flange steel plate 5, The fulcrum beam 6, the transverse partition 7, the internal prestressed beam 8 of the top plate, the internal prestressed beam 9 of the bottom plate, the external prestressed beam 10 and the connector 11, etc.

[0034] In this embodiment, the upper and lower edges of the combined steel pipe-steel plate web 3 are welded to the upper flange steel plate 4 and the lower flange steel plate 5 respectively, and the connecting piece 11 is arranged on the flange steel plate to form a complete steel member of the combined box girder. Two steel pipe-steel composite webs 3 are connected to the concrete roof 1 and the concrete bottom 2 through connectors 11 to form the main body of the composite box girder.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com