Stainless steel water meter case and production process thereof

A production process and water meter case technology, applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve problems such as air pollution, high labor intensity of workers, water metal pollution, etc., to improve product qualification rate and realize automation The effect of controlling and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

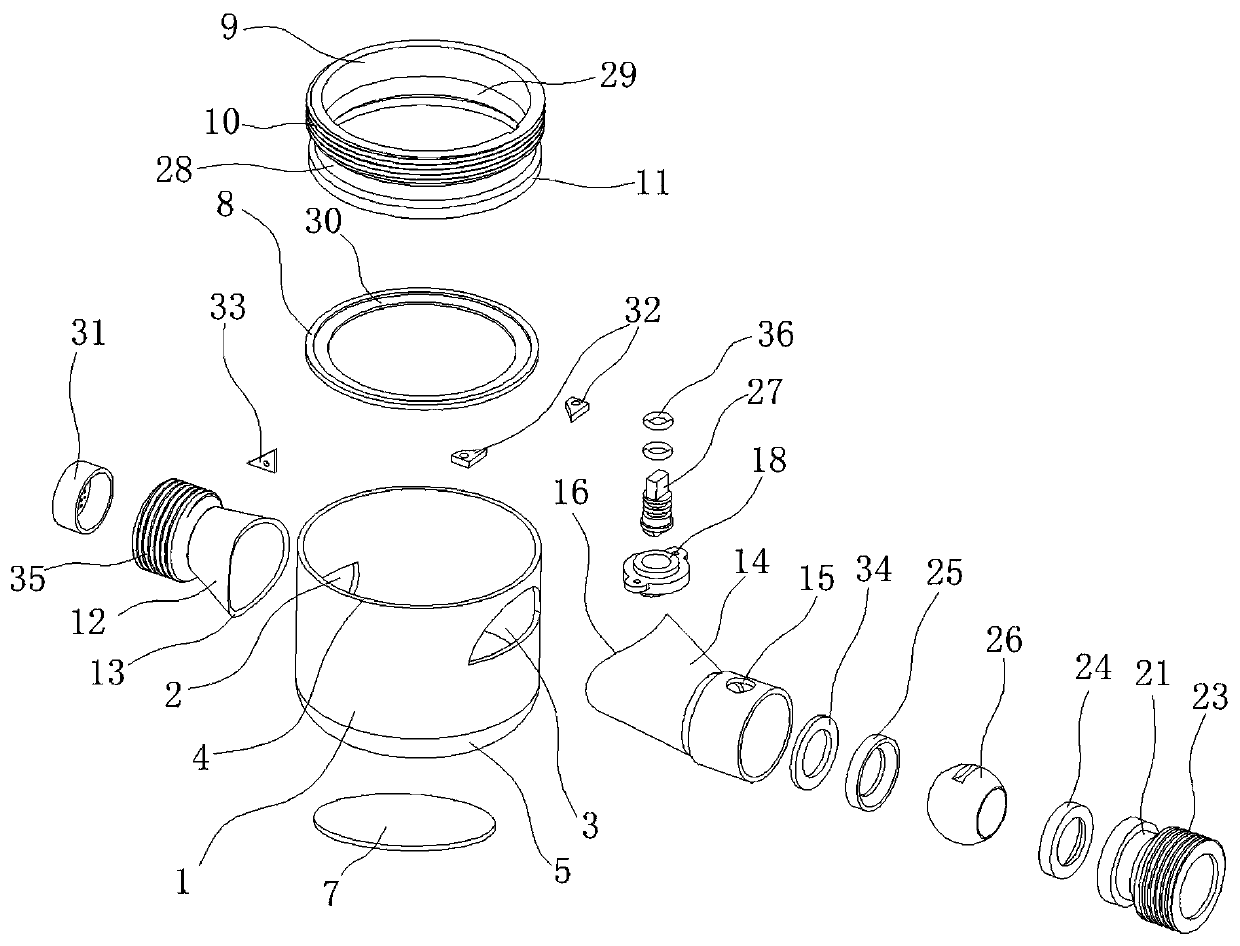

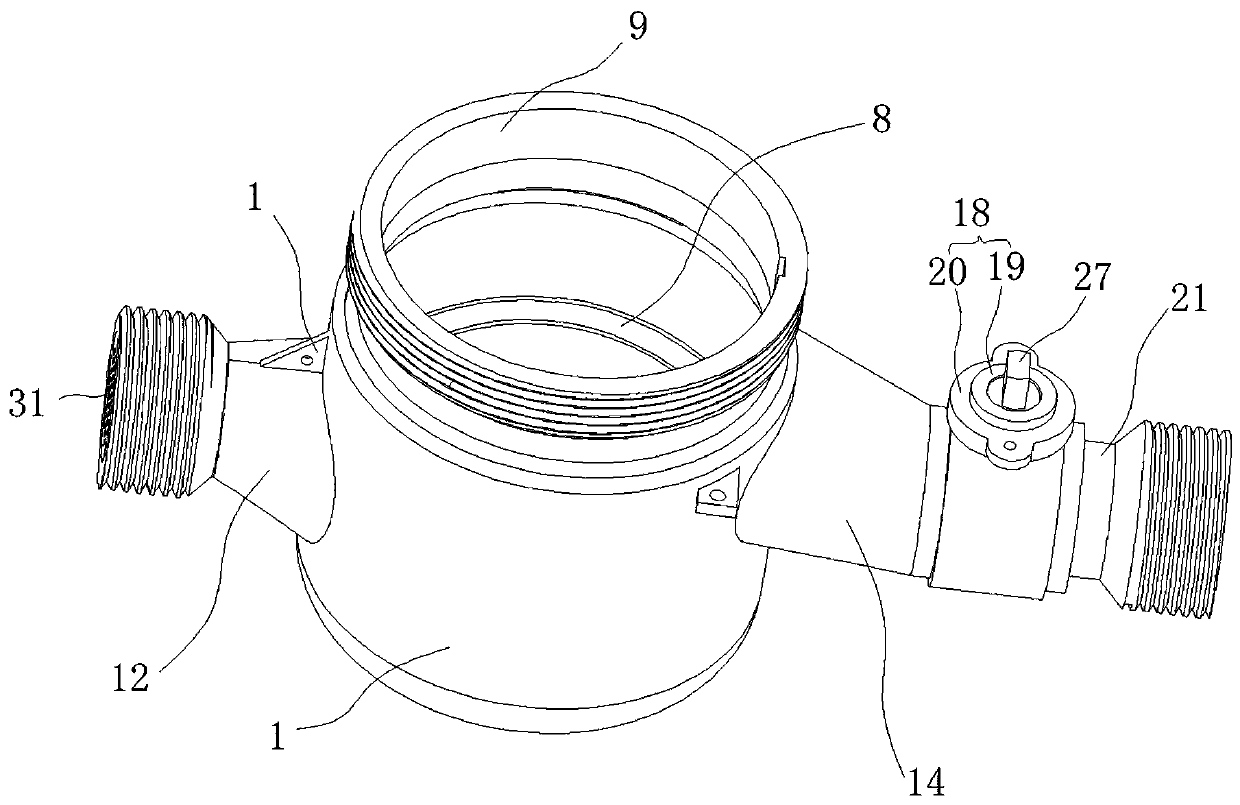

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] refer to Figure 1 ~ Figure 3 , a watch case body production process:

[0035] 1) The stainless steel round pipe is cut into a round pipe section 1 by a laser cutting machine, and the water inlet hole 2 and the water outlet hole 3 are passed through the laser cutting machine on the round pipe section 1. In order to facilitate matching and positioning, the water inlet hole 2 and the water outlet hole 3 are all arranged in a semicircle, and the upper end of the round pipe section 1 is formed with an upper end welding port 4, and the lower end of the round pipe section 1 is pressed out of a transition arc 5 and a lower end welding port 6 by a hydraulic press. In order to ensure the stability of the main body of the watch case, Make the diameter of the lower end welding port 6 smaller than the diameter of the stainless steel round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com