Preparation method of biomass algae-based lithium-sulfur battery positive electrode material

A lithium-sulfur battery and cathode material technology, applied in the field of electrochemistry, can solve the problems of low carbon porosity, complicated preparation process, and low sulfur loading capacity, and achieve improved electrical conductivity, low raw material cost, and improved charge-discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

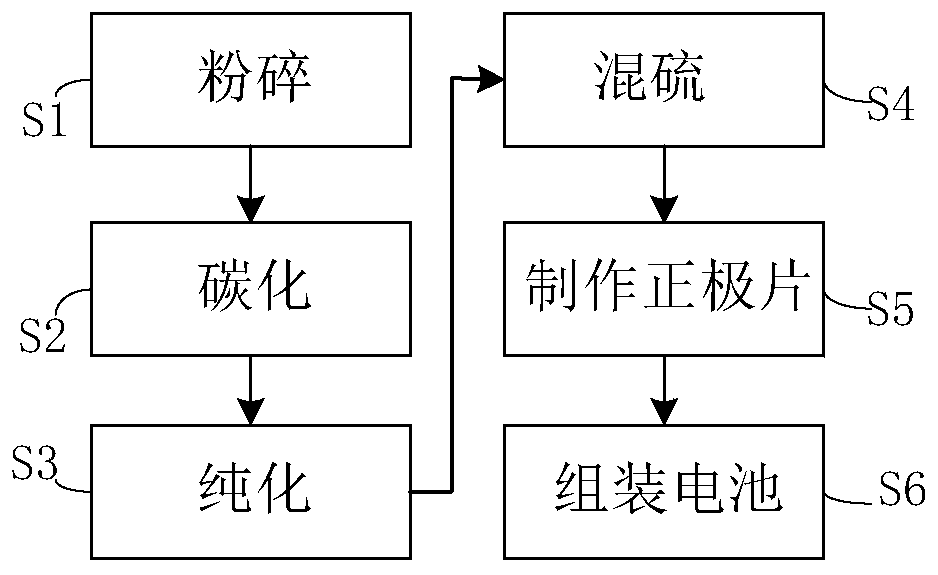

[0034] see figure 1 , figure 1 Schematic diagram of the preparation method for the lithium-sulfur battery cathode.

[0035] This embodiment discloses a preparation method of a seaweed-based sulfur-carbon composite material, a preparation method of a positive electrode sheet of a lithium-sulfur battery, and an assembly method of a lithium-sulfur battery.

[0036] Step S1, crushing: the seaweed is naturally dried and crushed with a multifunctional grinder, and the seaweed powder is filtered through a 60-mesh sieve.

[0037] It should be noted that natural seaweed is rich in raw materials, cheap and easy to obtain, renewable and environmentally friendly. The use of biomass seaweed as raw material to prepare high-performance carbonaceous material not only comprehensively utilizes biomass renewable raw materials, but also facilitates the control of air pollution and water pollution. Because the seaweed itself has a porous structure, the problems of environmental pollution and hi...

Embodiment 2

[0052] The other steps are the same as in Example 1, except that the heat preservation temperature in step S1 is changed from 700°C to 600°C; in step S4, "react in a vacuum oven at 155°C for 720 minutes" is changed to "in a vacuum oven at 140°C 700 minutes to react". Thus, a sulfur-carbon composite material is obtained.

[0053] In order to fully disclose the principles and technical effects of the present invention, the following description will be made in conjunction with the relevant drawings.

[0054] It should be noted that the way of mixing sulfur is not limited to the above-mentioned embodiments, for example, chemical coating of sulfur can also be used to replace the sulfur source with sodium thiosulfate.

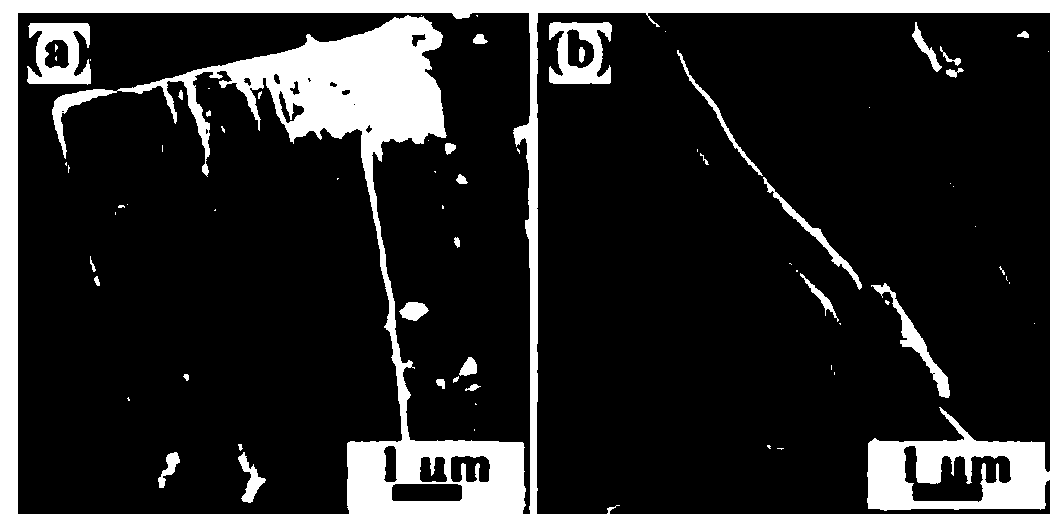

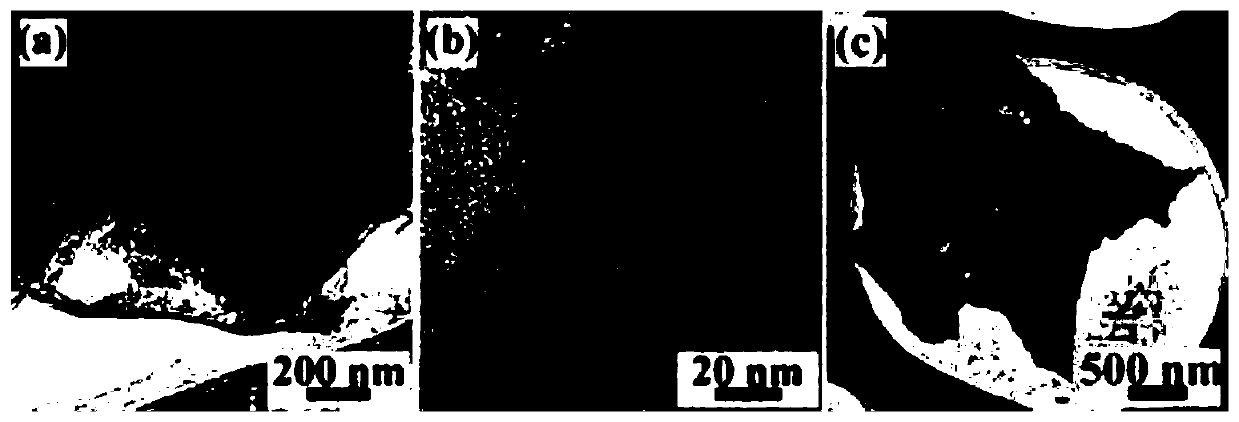

[0055] figure 2 Middle (a) is the scanning electron microscope analysis (SEM) picture taken of seaweed sample preparation before carbonization. It can be seen from the figure that the seaweed (enteromorpha) before carbonization has obvious hierarchical structure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com