Phase change material, phase change storage unit and preparation method thereof

A technology of phase change material and phase change memory, which is applied in the field of microelectronics, can solve the problems that the speed requirement of DRAM cannot be met, the data retention cannot be guaranteed, and the phase change speed of data loss is outstanding, achieving outstanding thermal stability, The effect of high yield and fast phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

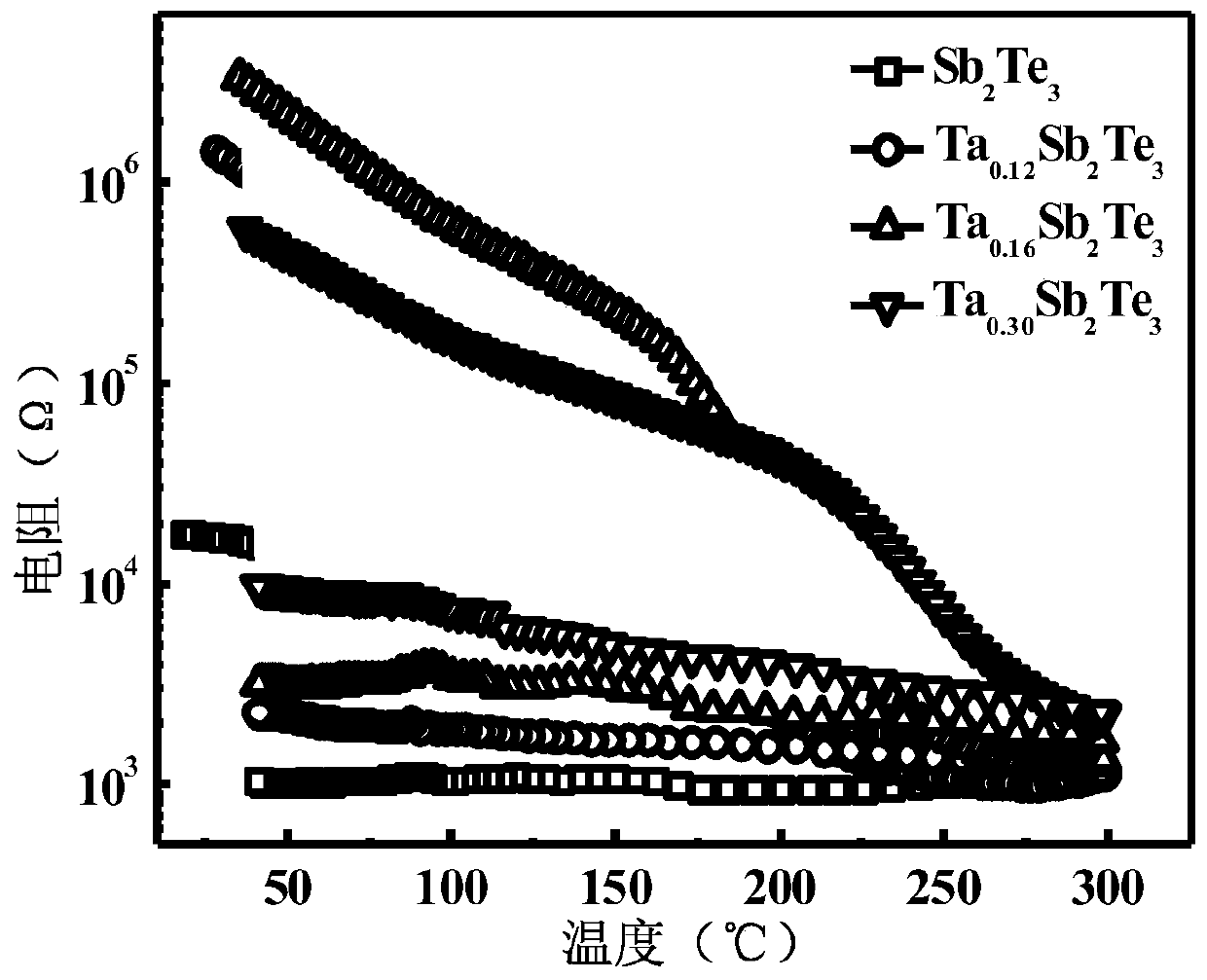

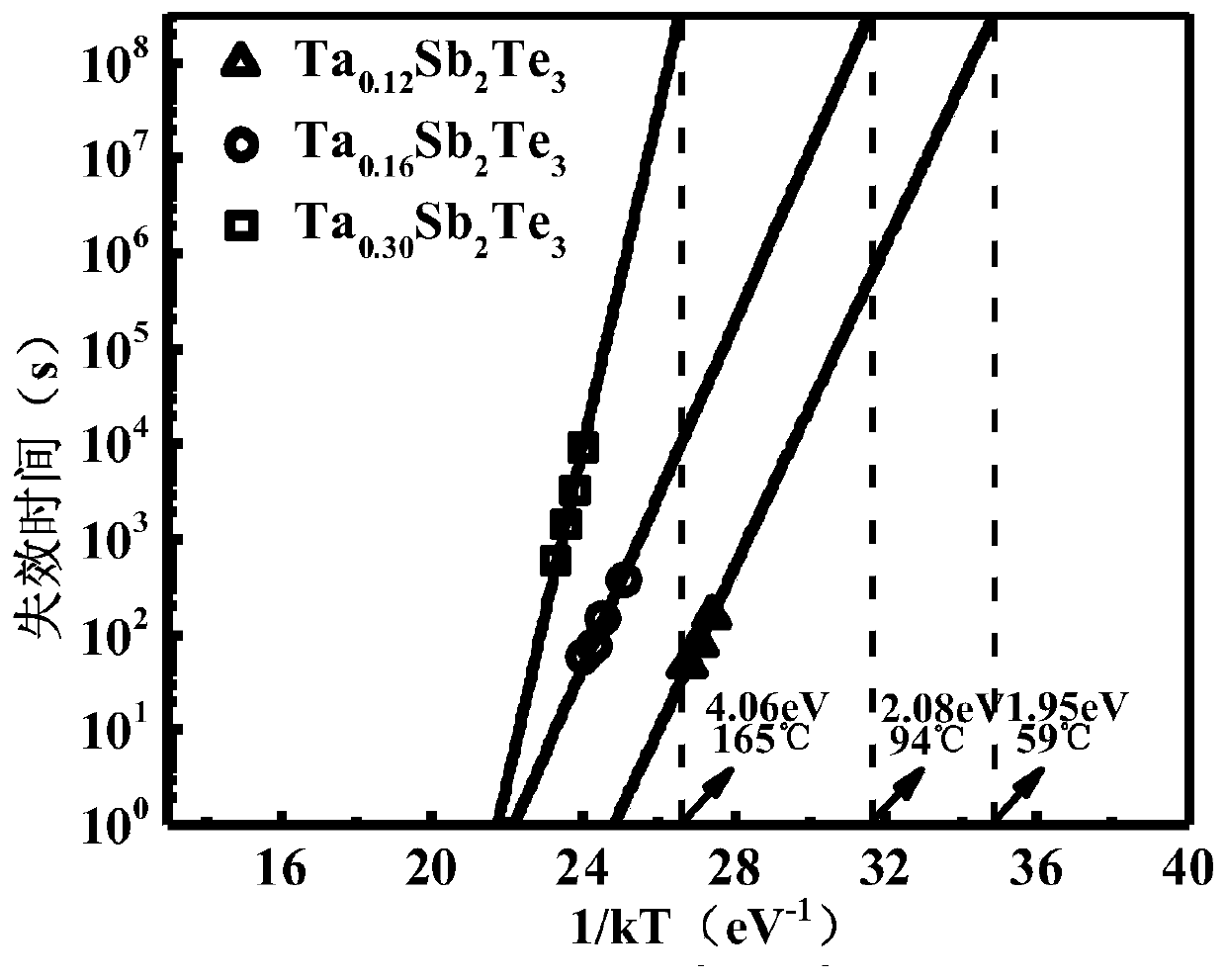

[0031] A phase change material is provided in this embodiment, the phase change material includes tantalum (Ta) element, antimony (Sb) element and tellurium (Te) element, and the chemical formula of the phase change material is Ta x Sb y Te z , wherein, x, y, z all refer to the atomic percentage of elements, and 1≤x≤25, 0.5≤y:z≤3, x+y+z=100.

[0032] Specifically, the Ta x Sb y Te z In , the contents of the three elements can be adjusted to obtain storage materials with different crystallization temperatures, resistivities, and crystallization activation energies. For example, the Ta x Sb y Te zAmong them, it can further satisfy 2≤x≤10, 25≤y≤45, 40≤z≤70, or further satisfy 3.5≤x≤9, 30≤y≤40, 50≤z≤60, and further satisfy 4≤ x≤8, 36≤y≤39.6, 54≤z≤59.4. In this embodiment, x, y, and z preferably satisfy: x=5.7, y=37.7, z=56.6, that is, the chemical formula of the phase change material is Ta 5.7 Sb 37.7 Te 56.6 .

[0033] Specifically, the Ta x Sb y Te z The phase-ch...

Embodiment 2

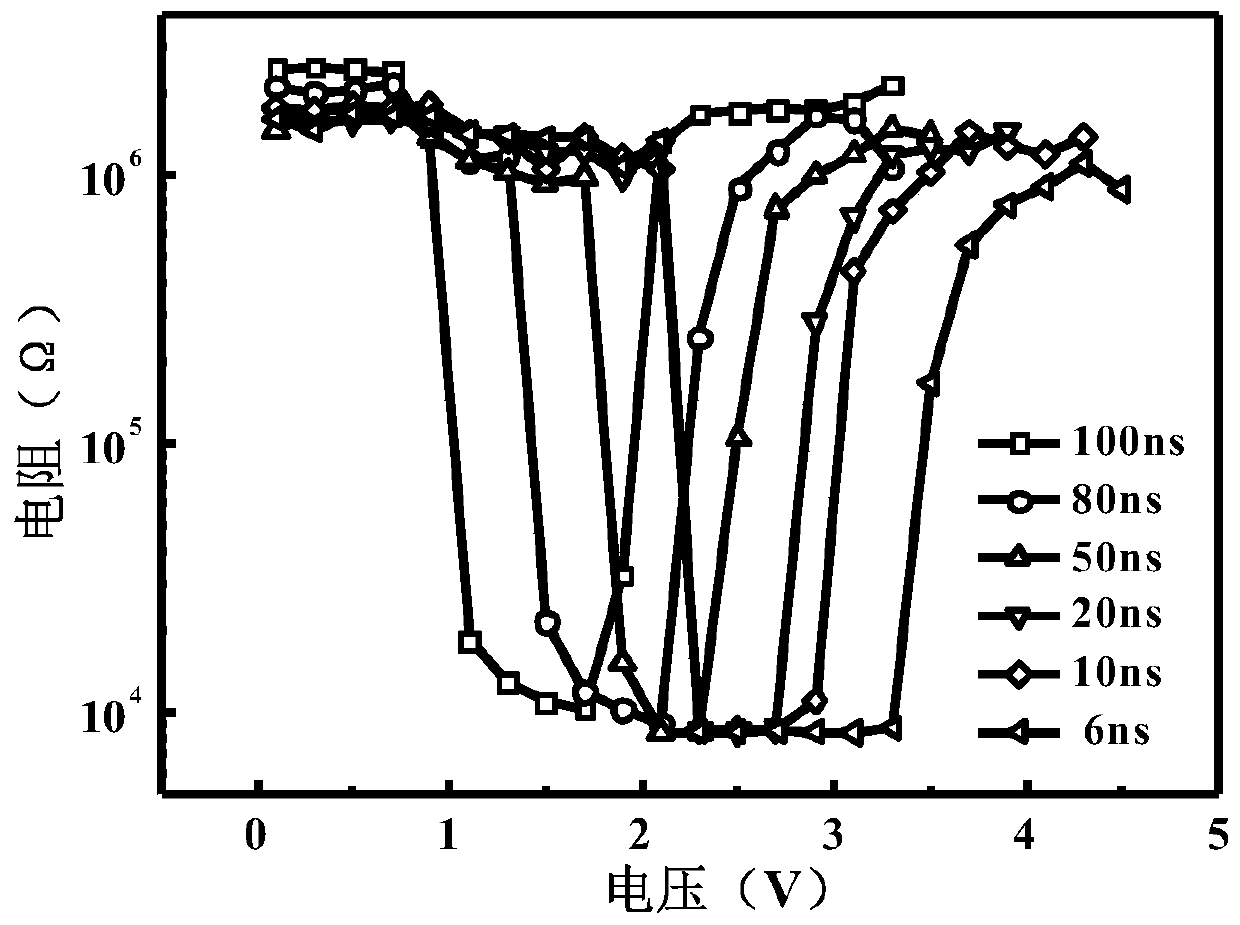

[0041] In this embodiment, a phase-change memory unit is provided, and the phase-change memory unit includes a lower electrode layer, an upper electrode layer, and a phase-change material layer between the lower electrode layer and the upper electrode layer. The variable material layer comprises Ta as described in Example 1 x Sb y Te z Phase change material, that is, the phase change material includes tantalum (Ta) element, antimony (Sb) element and tellurium (Te) element, and the chemical formula of the phase change material is Ta x Sb y Te z , wherein, x, y, z all refer to the atomic percentage of elements, and 1≤x≤25, 0.5≤y:z≤3, x+y+z=100.

[0042] As an example, the thickness range of the phase change material layer is 20nm-150nm.

[0043] As an example, an extraction electrode is formed on the upper electrode layer, through which the upper electrode layer and the lower electrode layer can be integrated with control switches, driving circuits and peripheral circuits o...

Embodiment 3

[0048] In this embodiment, a method for preparing a phase-change memory cell is provided, including the following steps:

[0049] S1: preparing the lower electrode layer;

[0050] S2: Prepare a phase-change material layer on the lower electrode layer, the phase-change material layer includes the phase-change material described in Example 1, that is, the phase-change material includes tantalum (Ta) elements, antimony (Sb) element and tellurium (Te) element, the chemical formula of the phase change material is Ta x Sb y Te z , wherein, x, y, z all refer to the atomic percentage of elements, and 1≤x≤25, 0.5≤y:z≤3, x+y+z=100. ;

[0051] S3: preparing an upper electrode layer on the phase change material layer.

[0052] As an example, the lower electrode layer may be prepared by a sputtering method, an evaporation method, a chemical vapor deposition (CVD), a plasma enhanced chemical vapor deposition (PECVD), or the like. The material of the lower electrode layer includes: one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com