A kind of cigs solar thin film cell of flexible substrate and preparation method thereof

A solar thin film and flexible substrate technology, applied in the field of solar cells, can solve problems such as affecting the overall output of solar cells, increasing contact resistance of solar cells, and inability to fully absorb incident light, so as to increase current and quantum efficiency, reduce contact resistance, The effect of improving battery output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

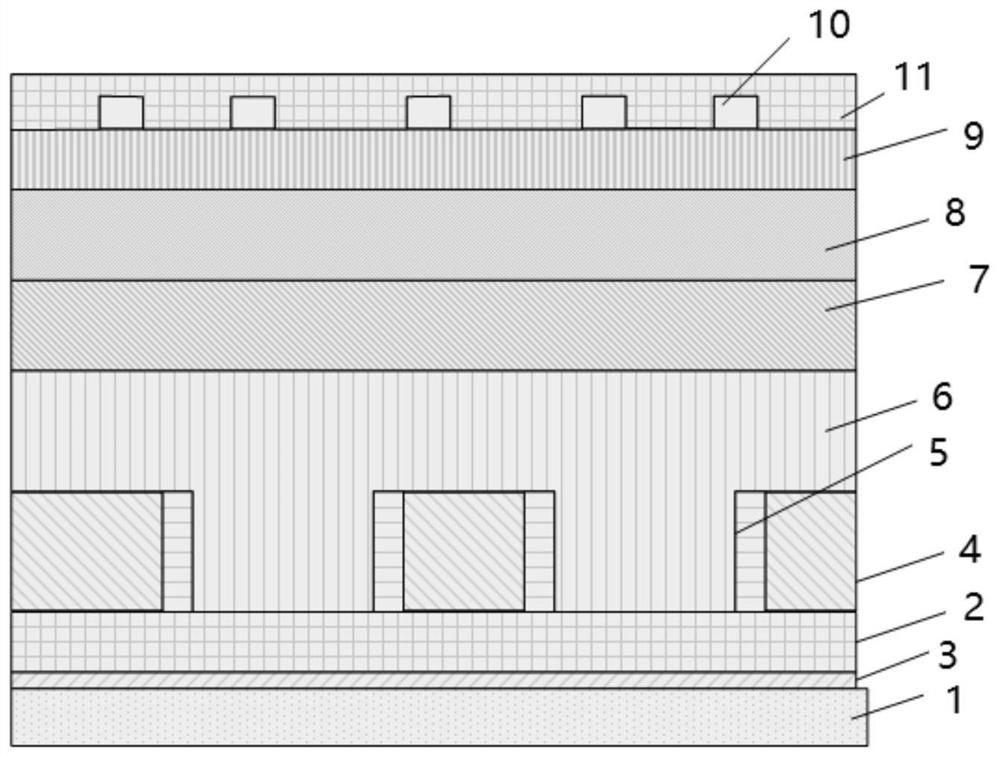

[0051] The invention discloses a CIGS solar thin film battery with a flexible substrate, as attached figure 1 As shown, it includes a flexible substrate 1 and a back electrode layer 2, an absorption layer 6, a buffer layer 7, an intrinsic zinc oxide high resistance layer 8, and a transparent surface electrode layer 9 stacked on the flexible substrate 1 in sequence; the absorption layer 6 and the back electrode An alkali metal-doped composite layer 4 is arranged between the layers 2; a channel is provided on the alkali metal-doped composite layer 4, and the absorption layer 6 is partially filled in the channel and directly physically contacts the back electrode layer 2; on the transparent surface electrode layer 9 A tin electrode is provided, and the tin electrode is welded on the surface of the transparent surface electrode by means of ultrasonic welding.

[0052] Specifically, the substrate 1 of the above-mentioned flexible substrate CIGS solar thin film cell is a flexible su...

Embodiment 2

[0088] The present invention also provides a method for preparing an electrode of a CIGS solar thin-film battery with a flexible substrate, comprising the following steps:

[0089] S1. Prepare an alkali metal-doped composite layer 4 on the flexible substrate 1 by magnetron sputtering, and then prepare a back electrode layer 2 on the alkali metal-doped composite layer 4;

[0090] S2. Prepare a corrugated Ag film on the back electrode layer 2, prepare an alkali metal-doped composite layer 4 on the corrugated Ag film layer, etch a channel in the middle of the alkali metal-doped composite layer 4, and fill the channel with an upper absorption layer 6;

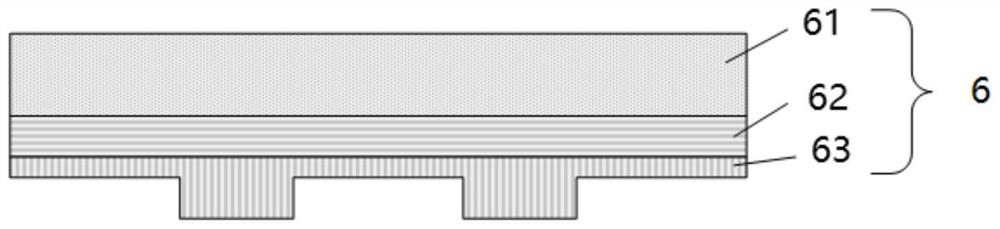

[0091] S3. Depositing the third CIGS absorbing layer 63 on the back electrode layer 2 and the alkali metal-doped composite layer 4 by multiple sputtering methods, and depositing the second CIGS absorbing layer 62 on the third CIGS absorbing layer 63 in sequence and a first CIGS absorber layer 61;

[0092] S4, preparing a buffer l...

Embodiment 3

[0113] Such as Figure 9 , Figure 10 and Figure 11 As shown, in the implementation of the present invention, a packaging structure 12 of a flexible solar thin film battery, the packaging structure 12 is rectangular, including a protective film, a structural film and a back film pressed from top to bottom. Usually, in order to facilitate processing, CIGS thin-film solar cells with flexible substrates are generally made into rectangles, and the core object of packaging is CIGS thin-film solar cells with flexible substrates, so the packaging structure 12 is rectangular. The size of the structural film and the CIGS solar thin film battery of the flexible substrate are the same; the size of the back film is larger than that of the CIGS solar thin film battery of the flexible substrate; the protective film includes the main body and the side, the main body is the same size as the CIGS solar thin film battery of the flexible substrate, and the side is It is arranged on the four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com