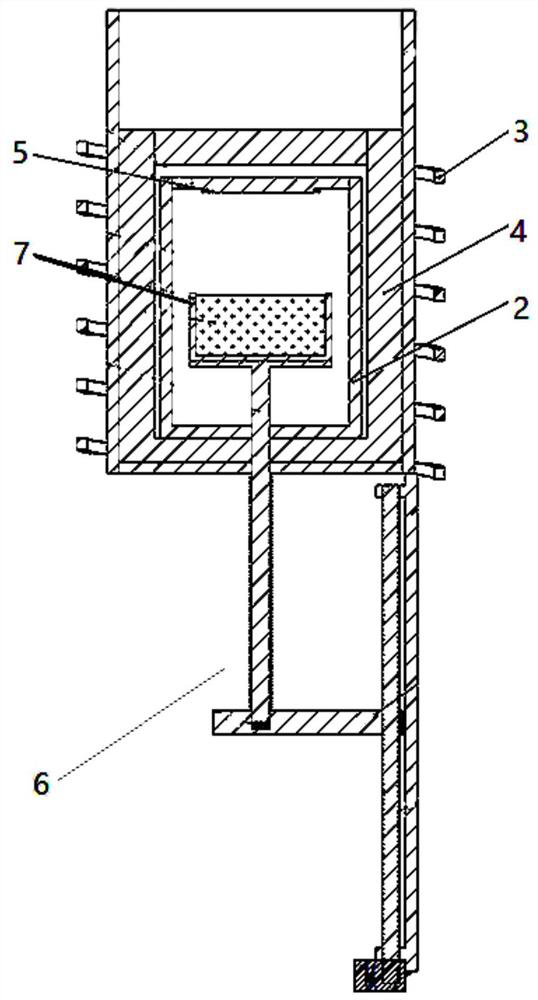

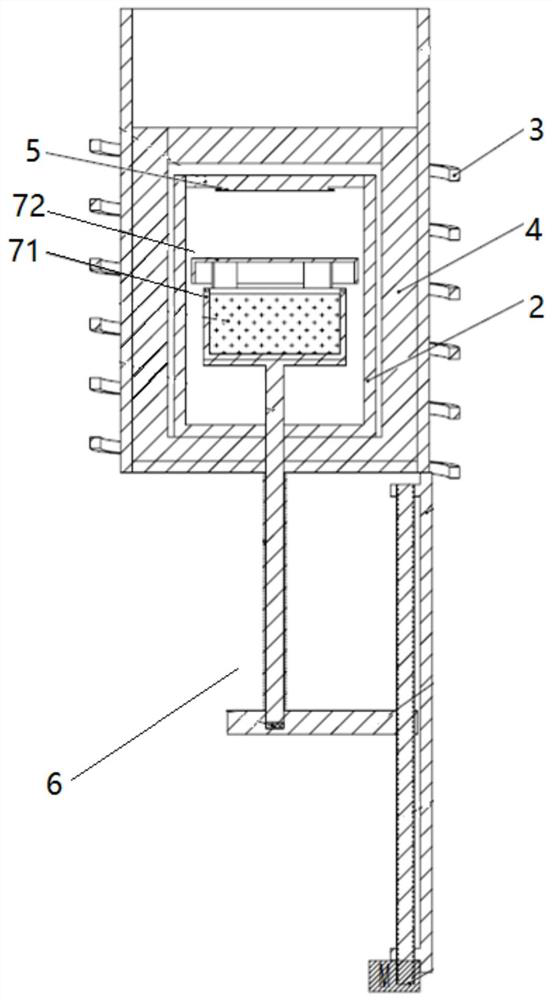

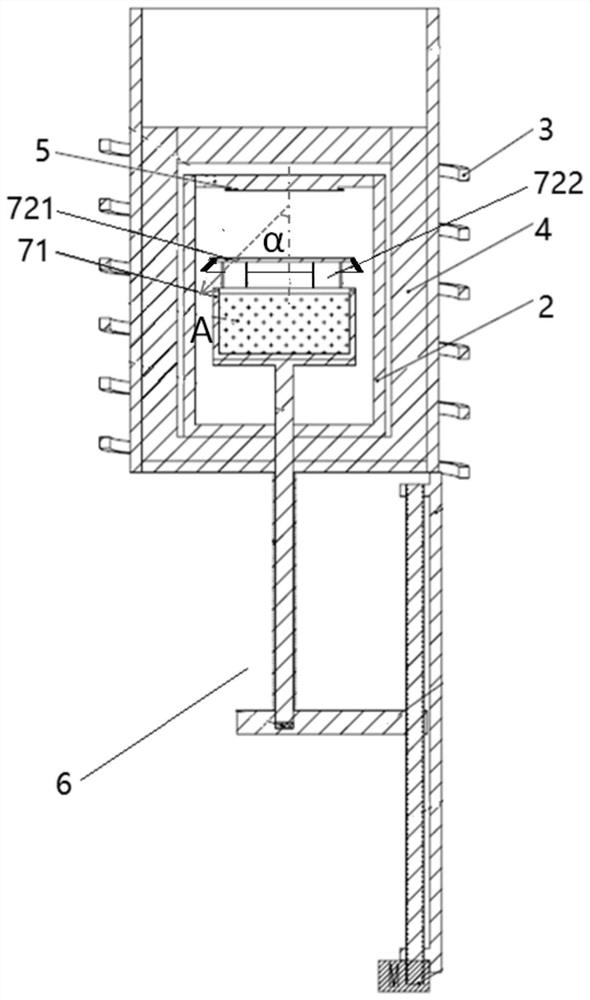

A kind of crystal growing device and its application

A technology of crystal growth and heating device, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of poor stability, accuracy and flexibility, poor stability of crystal growth environment, affecting the quality of growing crystals, etc. The effect of improving utilization rate, small roughness and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0084] As a specific implementation, the implementation of a method of using a crystal growth device includes the following steps:

[0085] (1) Load 1000g of SiC raw material into the barrel-shaped charging part, move the charging part to the lower part of the high temperature zone of the crucible to start the crystal growth program, and pump the pressure in the furnace chamber to 10 -5 Pa, raise the furnace temperature to 1773K in 1h, feed Ar gas, the pressure is 5-10 5 keep pa at this temperature for 2 hours; this step can remove impurities such as silicon carbide powder, water vapor, grease, etc. in the crucible and charging part;

[0086] (2) Move the middle and lower part of the charging part to the high temperature area, and reduce the pressure to 0-10 in 2 hours 4 Pa, the furnace temperature rises to 2273-2473K, and then enters the crystal growth stage; wherein, the crystal growth time is 50-200h, and Ar gas is continuously introduced, and the high temperature area is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com