A kind of high nitrogen content hyperbranched triazine-based char-forming agent and its preparation method and flame retardant composite material

A hyperbranched triazine and char-forming agent technology, which is applied in the field of polymer flame-retardant materials, can solve the problems of long reaction time, low nitrogen content, and poor thermal stability of char-forming agents in the synthesis of triazine-based char-forming agents, achieving Low cost, little damage to mechanical properties, enhanced flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of high nitrogen content hyperbranched triazine series char-forming agent, wherein: the structural general formula of described char-forming agent is as follows:

[0022]

[0023] in,

[0024] The reaction principle of the present invention is with reference to following reaction equation:

[0025]

Embodiment 2

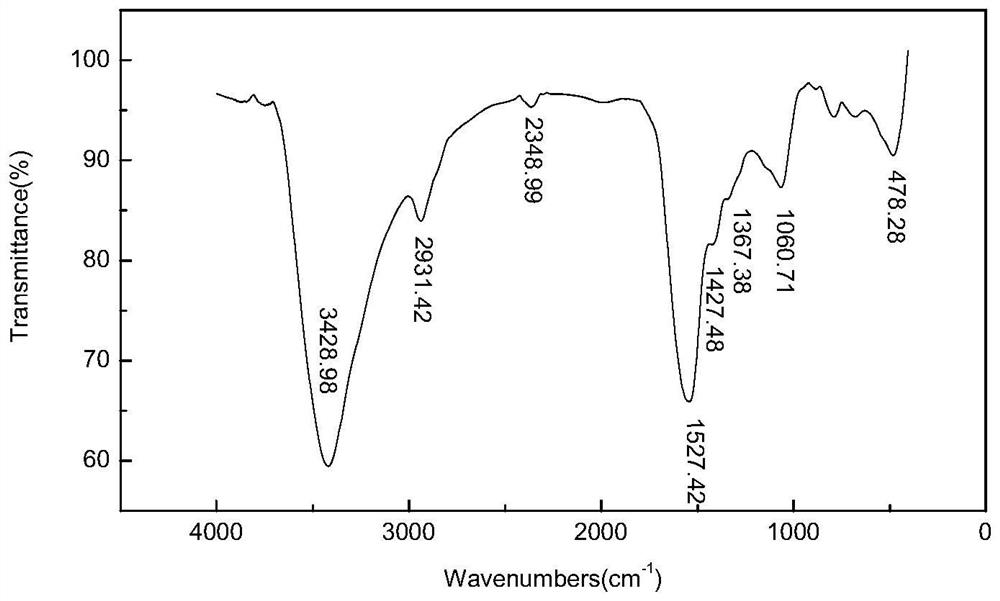

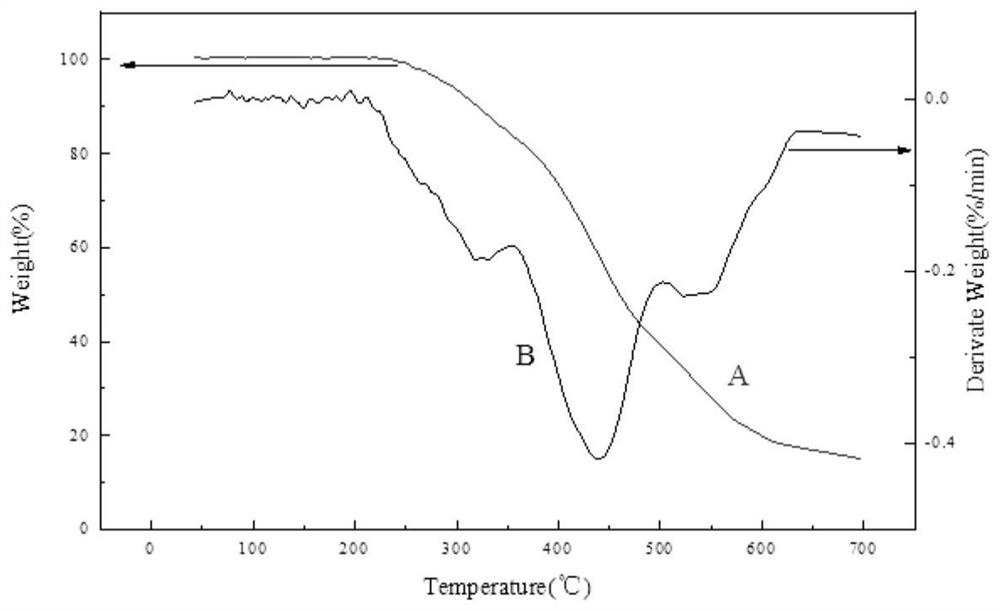

[0026] Embodiment 2: the preparation of a kind of hyperbranched triazine char-forming agent with high nitrogen content comprises the following steps: take 36.5g cyanuric chloride and put it into a 500mL four-necked flask, add 200mL acetone thereinto, place the device in In an ice-water bath, control the temperature of the solution at -10 to 10°C. In this example, it is 0°C, and use an electric stirring paddle to stir; put 20mL of diethanolamine solution into a constant pressure funnel, and add it dropwise to the trimer at a rate of 2 drops / second. In the acetone solution of cyanogen chloride, react continuously in a fume hood for 3 hours; place the device in an oil bath, control the temperature between 40 and 60°C. This embodiment is 50°C, and install a condensation reflux device; measure 7.5mL of di Mix ethylenetriamine and 100mL of 1.0mol / L sodium carbonate aqueous solution, add the mixture dropwise to the flask, control the speed at 1 drop / second, and continue to react in th...

Embodiment 3

[0034] Example 3: The prepared triazine intumescent flame retardant char-forming agent and ammonium polyphosphate APP are compounded into an intumescent flame retardant IFR in a ratio of 1:1, such as image 3 Shown are photos before and after the IFR expansion test. The intumescent flame retardant compounded by high nitrogen content hyperbranched triazine char-forming agent and ammonium polyphosphate in a ratio of 1:1 was pressed into a disc (diameter 1.2cm, thickness 2mm, The total mass is 0.3g) put it on the aluminum foil paper, mark it, put it into a box-type resistance furnace at 400°C, and take it out after 5 minutes.

[0035] Intumescent flame retardant IFR was blended with PP to prepare flame-retardant composite materials. The material ratio of flame-retardant composite materials is shown in Table 1, and the oxygen index test results are shown in Table 2. After the IFR is ground evenly, it is melt-blended with PP to obtain a flame-retardant composite material. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com